1030 - Embedded Plate Design - 4_s7.00 2l4r8

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3i3n4

Overview 26281t

& View 1030 - Embedded Plate Design - 4_s7.00 as PDF for free.

More details 6y5l6z

- Words: 1,300

- Pages: 9

1030 - UD ISE Building

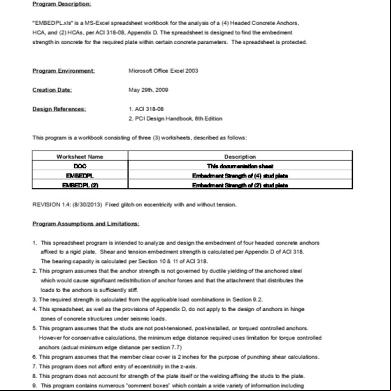

EMBEDDED PLATE DESIGN - 4/S7.00 (REF: ANCHORING TO CONCRETE - ACI Appendix D) LAY-OUT:

1 1/2"

Connection Plate/Angle to be designed separately

7@6 "

dm = 24"

Ax2 d = 11.14"

V

Ax1 Ay

1 1/2"

A

Stress distribution per Case II (AISC 13th Ed. Manual p7-12) This Connection plate/Angle justifies the assumed stress distribution as it stiffens the embed plate PL1" - A36

1 1/2"

6"

1 1/2"

16 - 3/4in. dia. ASTM A108 Grade 1015 or 1020 (6" long min)

Page 1 of 9

1030 - UD ISE Building

REQUIREMENT: A, Axial Load = V, Shear Load = Ax2, Axial Load =

80.00 35.00 60.00

kips <-- From brace kips <-- From beam kips <-- From beam

CALCULATION: Brace Slope: Ay

=

1.0

80 (1) √ [ (1) ² + (0.82) ² ]

= Ax1

=

/ 0.82

61.9

kips

80 (0.82) √ [ (1) ² + (0.82) ² ] 50.73

=

kips

Discussion: Since the diagonal and the horizontal share the same connection, (forces are concurrent) there will be a force interaction. Thus, Ax Ax

= =

max (Ax1, Ax2) kips 60.00

Total Shear, VT = Total Shear, VT =

Ay + V 96.86

kips <- See attached sheet for the calculation.

Per AISC, bolts/stud above the neutral axis are subjected to the tensile force and the effect of the prying action Tensile Load, T =

Ax * d / dm where: Ax = d = dm =

Tensile Load, T =

27.85

60.0 11.14 24

kips in in

kips <- See attached sheet for the calculation.

The thickness required to eliminate prying action is tmin

=

√

4.44 T b' p Fu

where: T= T=

required strength 27.85 kips

b' = g - d - tp where: g = stud's gage = 6.0 in

Page 2 of 9

1030 - UD ISE Building

d = stud diameter = in 0.75 tp = connection plate thickness = 0.50 in b' = p= p=

2.375

<-- assumed

in

tributary length per pair of studs for a tee 6.0 in

Fu = Tensile strength of embed plate Fu = 65.0 in

tmin

=

0.868

in

<

1.00

in.

(OK)

Page 3 of 9

1030 - UD ISE Building

SHEAR CAPACITY OF STUDS (REF: ANCHORING TO CONCRETE - ACI Appendix D)

Stud Diameter, do :

3/4

in. dia. ASTM A108 Grade 1015 or 1020

Fy

= =

Yield Strength of Stud 51 ksi

Fu

= =

Tensile Strength of Stud 65 ksi

L

= =

Nominal Length of Stud in 6.00

tp

= =

Embed Plate Thickness in 1.00

Ase

= =

Shank Area 0.442 in²

ths

= =

Head Thickness, in 0.375 in

hef

= = =

effective embedment depth L + tp - ths - 1/8 6.500 in

fc'

= =

concrete compresive strength 5 ksi

Steel Strength of Studs in Shear Vsa

=

n * 0.6 * Ase * futa

( ø = 0.65 )

where:

øVsa

=

Ase

= =

effective cross-sectional area of studs in² 0.442

futa

= =

ultimate tensile strength of studs 65 ksi

n

= =

no. of studs 16.00 in

179.19

kips

Concrete Breakout Strength of Studs in Shear Studs are not located near free edge perpendicular to the application of the load. Therefore, breakout for shear is not applicable.

Concrete Pryout Strength of Anchor in Shear

Page 4 of 9

1030 - UD ISE Building

Vg

=

k * Ncbg

ø = 0.70

where: k k

= = =

1.0 for hef < 2.5 in 2.0 for hef > 2.5 in 2.00

Ng

=

(ANC/ANCO) * ψec,N * ψed,N * ψc,N * ψ,N * Nb

ψec,N

= =

eccentricity factor 1 <1 1 + (2eN'/3hef) eN'

=

in

0.00

ψec,N

=

1.000

ψed,N

=

1.0

=

0.7 + 0.3

if (Ca,min > 1.5hef)

ca,min

Ca,min 1.5hef

if Ca,min < 1.5hef

15.00

=

in

ψed,N

=

1.000

ψc,N

=

1.000

(cracked concrete)

ψ,N

=

1.000

(for cast-in anchors in cracked concrete)

Nb

=

kc

√fc' (hef)1.5 kc

Nb

=

ANCO

= = =

=

28123.3

24

(for cast-in anchors)

lbs

(2*1.5hef) * (2*1.5hef) 9*hef² 380.25 in² x

sx

x

y

sy

y

Page 5 of 9

1030 - UD ISE Building

ANC

=

(2y + sy) (2x + sx) where: y = =

ANC Ng

=

=

min (1.5hef , c'a1) ; c'a1 = 180 in 9.75 in

x

= =

sy

=

42.00

in

sx

=

6.00

in

1568.25

115988

min (1.5hef , c'a2) 9.75 in

c'a2 =

15

in

in²

lbs

therefore, øVg øVg

= =

162383 162.383

lbs kips

SUMMARY: Steel Strength of Studs in Shear Concrete Pryout Strength of Anchor in Shear

Controlling limit state, øV =

162.38

kips

>

179.19 162.38

kips kips

96.86

kips

(OK)

Page 6 of 9

1030 - UD ISE Building

TENSILE CAPACITY OF STUDS (REF: ANCHORING TO CONCRETE - ACI Appendix D)

Stud Diameter, do :

3/4

in. dia. ASTM A108 Grade 1015 or 1020

Fy

= =

Yield Strength of Stud 51 ksi

Fu

= =

Tensile Strength of Stud 65 ksi

L

= =

Nominal Length of Stud in 6.00

tp

= =

Embed Plate Thickness in 1.00

Ase

= =

Shank Area 0.442 in²

Abrg

= =

Bearing Area 0.790 in²

ths

= =

Head Thickness, in 0.375 in

hef

= = =

effective embedment depth L + tp - ths - 1/8 6.500 in

fc'

= =

concrete compresive strength 5 ksi

Steel Strength of Studs in Tension =

Nsa

n * Ase * futa

( ø = 0.75 )

where:

øNsa

=

Ase

= =

effective cross-sectional area of studs 0.442 in²

futa

= =

ultimate tensile strength of studs 65 ksi

n

= =

no. of studs 8.00 in

172.30

kips

Concrete Breakout Strength of Studs in Tension Ng

=

(ANC/ANCO) * ψec,N * ψed,N * ψc,N * ψ,N * Nb

ø = 0.70

where:

Page 7 of 9

1030 - UD ISE Building

=

ψec,N

=

eccentricity factor 1 <1 1 + (2eN'/3hef) eN'

=

0.00

ψec,N

=

ψed,N

=

1.0

=

0.7 + 0.3

in

1.000 if (Ca,min > 1.5hef)

ca,min

Ca,min 1.5hef

=

if Ca,min < 1.5hef

15.00

in

ψed,N

=

1.000

ψc,N

=

1.000

(cracked concrete)

ψ,N

=

1.000

(for cast-in anchors in cracked concrete)

Nb

=

kc

√fc' (hef)1.5 kc

Nb

=

ANCO

= = =

=

28123.3

24

(for cast-in anchors)

lbs

(2*1.5hef) * (2*1.5hef) 9*hef² in² 380.25 sx

x

x

y

sy

y

ANC

=

(2y + sy) (2x + sx)

where: y = = x

=

min (1.5hef , c'a1) ; c'a1 = 180 in in 9.75 min (1.5hef , c'a2)

c'a2 =

15

in

Page 8 of 9

1030 - UD ISE Building

ANC øNg øNg

9.75

in

sy

=

18.00

in

sx

=

6.00

in

956.25

=

49507 49.51

= =

=

in²

lbs kips

Concrete Pullout Strength of Studs in Tension øNpn

=

n * ψc,P * NP

ø = 0.70

where:

øNpn

=

n

= =

ψc,P

=

Abrg

= =

bearing area of studs 0.79 in²

Np

= =

8*Abrg *f'c 31.6

252.8

no. of studs in 8.00 (cracked concrete)

1.0

(for 0.75'' dia studs)

kips

kips

Concrete side-face blowout strength of studs in tension The side-face blowout failure mode must be investigated when the edge distance is less than 0.4 hef edge dist. =

in

15

>

0.4 hef =

2.60

in

(OK)

SUMMARY: Steel Strength of Studs in Tension Concrete Breakout Strength of Studs in Tension Concrete Pullout Strength of Studs in Tension

Controlling limit state, øV =

49.51

kips

>

1.20

(OK)

172.30 49.51 252.80

kips kips kips

27.85

kips

(OK)

Check Interaction Equation Na Nn/Ω

+

Va vn/Ω

<

1.2

27.9 49.5

+

96.9 162

=

1.16

<

Page 9 of 9

EMBEDDED PLATE DESIGN - 4/S7.00 (REF: ANCHORING TO CONCRETE - ACI Appendix D) LAY-OUT:

1 1/2"

Connection Plate/Angle to be designed separately

7@6 "

dm = 24"

Ax2 d = 11.14"

V

Ax1 Ay

1 1/2"

A

Stress distribution per Case II (AISC 13th Ed. Manual p7-12) This Connection plate/Angle justifies the assumed stress distribution as it stiffens the embed plate PL1" - A36

1 1/2"

6"

1 1/2"

16 - 3/4in. dia. ASTM A108 Grade 1015 or 1020 (6" long min)

Page 1 of 9

1030 - UD ISE Building

REQUIREMENT: A, Axial Load = V, Shear Load = Ax2, Axial Load =

80.00 35.00 60.00

kips <-- From brace kips <-- From beam kips <-- From beam

CALCULATION: Brace Slope: Ay

=

1.0

80 (1) √ [ (1) ² + (0.82) ² ]

= Ax1

=

/ 0.82

61.9

kips

80 (0.82) √ [ (1) ² + (0.82) ² ] 50.73

=

kips

Discussion: Since the diagonal and the horizontal share the same connection, (forces are concurrent) there will be a force interaction. Thus, Ax Ax

= =

max (Ax1, Ax2) kips 60.00

Total Shear, VT = Total Shear, VT =

Ay + V 96.86

kips <- See attached sheet for the calculation.

Per AISC, bolts/stud above the neutral axis are subjected to the tensile force and the effect of the prying action Tensile Load, T =

Ax * d / dm where: Ax = d = dm =

Tensile Load, T =

27.85

60.0 11.14 24

kips in in

kips <- See attached sheet for the calculation.

The thickness required to eliminate prying action is tmin

=

√

4.44 T b' p Fu

where: T= T=

required strength 27.85 kips

b' = g - d - tp where: g = stud's gage = 6.0 in

Page 2 of 9

1030 - UD ISE Building

d = stud diameter = in 0.75 tp = connection plate thickness = 0.50 in b' = p= p=

2.375

<-- assumed

in

tributary length per pair of studs for a tee 6.0 in

Fu = Tensile strength of embed plate Fu = 65.0 in

tmin

=

0.868

in

<

1.00

in.

(OK)

Page 3 of 9

1030 - UD ISE Building

SHEAR CAPACITY OF STUDS (REF: ANCHORING TO CONCRETE - ACI Appendix D)

Stud Diameter, do :

3/4

in. dia. ASTM A108 Grade 1015 or 1020

Fy

= =

Yield Strength of Stud 51 ksi

Fu

= =

Tensile Strength of Stud 65 ksi

L

= =

Nominal Length of Stud in 6.00

tp

= =

Embed Plate Thickness in 1.00

Ase

= =

Shank Area 0.442 in²

ths

= =

Head Thickness, in 0.375 in

hef

= = =

effective embedment depth L + tp - ths - 1/8 6.500 in

fc'

= =

concrete compresive strength 5 ksi

Steel Strength of Studs in Shear Vsa

=

n * 0.6 * Ase * futa

( ø = 0.65 )

where:

øVsa

=

Ase

= =

effective cross-sectional area of studs in² 0.442

futa

= =

ultimate tensile strength of studs 65 ksi

n

= =

no. of studs 16.00 in

179.19

kips

Concrete Breakout Strength of Studs in Shear Studs are not located near free edge perpendicular to the application of the load. Therefore, breakout for shear is not applicable.

Concrete Pryout Strength of Anchor in Shear

Page 4 of 9

1030 - UD ISE Building

Vg

=

k * Ncbg

ø = 0.70

where: k k

= = =

1.0 for hef < 2.5 in 2.0 for hef > 2.5 in 2.00

Ng

=

(ANC/ANCO) * ψec,N * ψed,N * ψc,N * ψ,N * Nb

ψec,N

= =

eccentricity factor 1 <1 1 + (2eN'/3hef) eN'

=

in

0.00

ψec,N

=

1.000

ψed,N

=

1.0

=

0.7 + 0.3

if (Ca,min > 1.5hef)

ca,min

Ca,min 1.5hef

if Ca,min < 1.5hef

15.00

=

in

ψed,N

=

1.000

ψc,N

=

1.000

(cracked concrete)

ψ,N

=

1.000

(for cast-in anchors in cracked concrete)

Nb

=

kc

√fc' (hef)1.5 kc

Nb

=

ANCO

= = =

=

28123.3

24

(for cast-in anchors)

lbs

(2*1.5hef) * (2*1.5hef) 9*hef² 380.25 in² x

sx

x

y

sy

y

Page 5 of 9

1030 - UD ISE Building

ANC

=

(2y + sy) (2x + sx) where: y = =

ANC Ng

=

=

min (1.5hef , c'a1) ; c'a1 = 180 in 9.75 in

x

= =

sy

=

42.00

in

sx

=

6.00

in

1568.25

115988

min (1.5hef , c'a2) 9.75 in

c'a2 =

15

in

in²

lbs

therefore, øVg øVg

= =

162383 162.383

lbs kips

SUMMARY: Steel Strength of Studs in Shear Concrete Pryout Strength of Anchor in Shear

Controlling limit state, øV =

162.38

kips

>

179.19 162.38

kips kips

96.86

kips

(OK)

Page 6 of 9

1030 - UD ISE Building

TENSILE CAPACITY OF STUDS (REF: ANCHORING TO CONCRETE - ACI Appendix D)

Stud Diameter, do :

3/4

in. dia. ASTM A108 Grade 1015 or 1020

Fy

= =

Yield Strength of Stud 51 ksi

Fu

= =

Tensile Strength of Stud 65 ksi

L

= =

Nominal Length of Stud in 6.00

tp

= =

Embed Plate Thickness in 1.00

Ase

= =

Shank Area 0.442 in²

Abrg

= =

Bearing Area 0.790 in²

ths

= =

Head Thickness, in 0.375 in

hef

= = =

effective embedment depth L + tp - ths - 1/8 6.500 in

fc'

= =

concrete compresive strength 5 ksi

Steel Strength of Studs in Tension =

Nsa

n * Ase * futa

( ø = 0.75 )

where:

øNsa

=

Ase

= =

effective cross-sectional area of studs 0.442 in²

futa

= =

ultimate tensile strength of studs 65 ksi

n

= =

no. of studs 8.00 in

172.30

kips

Concrete Breakout Strength of Studs in Tension Ng

=

(ANC/ANCO) * ψec,N * ψed,N * ψc,N * ψ,N * Nb

ø = 0.70

where:

Page 7 of 9

1030 - UD ISE Building

=

ψec,N

=

eccentricity factor 1 <1 1 + (2eN'/3hef) eN'

=

0.00

ψec,N

=

ψed,N

=

1.0

=

0.7 + 0.3

in

1.000 if (Ca,min > 1.5hef)

ca,min

Ca,min 1.5hef

=

if Ca,min < 1.5hef

15.00

in

ψed,N

=

1.000

ψc,N

=

1.000

(cracked concrete)

ψ,N

=

1.000

(for cast-in anchors in cracked concrete)

Nb

=

kc

√fc' (hef)1.5 kc

Nb

=

ANCO

= = =

=

28123.3

24

(for cast-in anchors)

lbs

(2*1.5hef) * (2*1.5hef) 9*hef² in² 380.25 sx

x

x

y

sy

y

ANC

=

(2y + sy) (2x + sx)

where: y = = x

=

min (1.5hef , c'a1) ; c'a1 = 180 in in 9.75 min (1.5hef , c'a2)

c'a2 =

15

in

Page 8 of 9

1030 - UD ISE Building

ANC øNg øNg

9.75

in

sy

=

18.00

in

sx

=

6.00

in

956.25

=

49507 49.51

= =

=

in²

lbs kips

Concrete Pullout Strength of Studs in Tension øNpn

=

n * ψc,P * NP

ø = 0.70

where:

øNpn

=

n

= =

ψc,P

=

Abrg

= =

bearing area of studs 0.79 in²

Np

= =

8*Abrg *f'c 31.6

252.8

no. of studs in 8.00 (cracked concrete)

1.0

(for 0.75'' dia studs)

kips

kips

Concrete side-face blowout strength of studs in tension The side-face blowout failure mode must be investigated when the edge distance is less than 0.4 hef edge dist. =

in

15

>

0.4 hef =

2.60

in

(OK)

SUMMARY: Steel Strength of Studs in Tension Concrete Breakout Strength of Studs in Tension Concrete Pullout Strength of Studs in Tension

Controlling limit state, øV =

49.51

kips

>

1.20

(OK)

172.30 49.51 252.80

kips kips kips

27.85

kips

(OK)

Check Interaction Equation Na Nn/Ω

+

Va vn/Ω

<

1.2

27.9 49.5

+

96.9 162

=

1.16

<

Page 9 of 9