Feed Water System 53545n

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3i3n4

Overview 26281t

& View Feed Water System as PDF for free.

More details 6y5l6z

- Words: 540

- Pages: 2

Aalborg Solutions No. 2 · August 2001

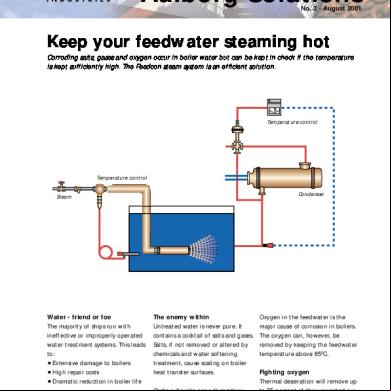

Keep your feedwater steaming hot Corroding salts, gases and oxygen occur in boiler water but can be kept in check if the temperature is kept sufficiently high. The Feedcon steam system is an efficient solution.

Temperature control

Temperature control Condenser

Steam

Water - friend or foe

The enemy within

Oxygen in the feedwater is the

The majority of ships run with

Untreated water is never pure. It

major cause of corrosion in boilers.

ineffective or improperly operated

contains a cocktail of salts and gases. The oxygen can, however, be

water treatment systems. This leads

Salts, if not removed or altered by

removed by keeping the feedwater

to:

chemicals and water softening

temperature above 85ºC.

Extensive High

damage to boilers

repair costs

Dramatic

treatment, cause scaling on boiler heat transfer surfaces.

reduction in boiler life

Fighting oxygen Thermal deaeration will remove up

Carbon dioxide gas will combine

to 75 percent of the unwanted oxy-

A proper system for boiler feed-

with water to form carbonic acid,

gen in feedwater. Chemical oxygen

water will maintain normal boiler

which attacks the boiler and the

scavengers can absorb the remain-

life expectancy up to 30 years.

condensation system.

ing oxygen.

Fighting carbon dioxide

ally offered together with new

Heating of boiler feedwater can

boiler plants but generally decided

keep the carbon dioxide in check.

against by the shipyards, much to

At a temperature of 85 to 90°C,

the regret of shipowners and ship

carbon dioxide is in its steam phase,

managers later. The Feedcon system

and the gas is harmless in this state.

is, however, easy to install and

The temperature must be maintain-

operate.

ed, or corrosion will be triggered

A Feedcon steam injection system

by the changes in the carbon diox-

in a closed, vented feedwater tank

ide contents. Alkaline boiler water

will ensure that the feedwater tem-

SUNROD™ pin tube damaged by

and chemical treatment can help

perature is maintained at a mini-

oxygen corrosion (pittings).

neutralise the effects of the gas as

mum of 85°C, thus preventing oxy-

well as handle the salt problem.

gen corrosion.

being returned to the cascade tank or hotwell tank. This means that

Aalborg’s money-saving Feedcon system

A system for controlling conden-

more steam has to be injected to

sate temperatures also solves the

maintain the temperature. The

Aalborg Industries has a highly

related and costly problem in con-

Feedcon system prevents this waste

effective solution to solving feed-

densate water from the system

of energy and saves the ship opera-

water problems. The system is usu-

which is often super-cooled before

tors unnecessary costs.

Keep your feedwater steaming hot and you will gain A

longer boiler life

Lower

operating costs

Higher

steam output

Less

maintenance

Oxygen content (ppm)

Lower

consumption of chemicals

At atmospheric pressure

Water temperature (°C)

Aalborg Solutions is published by Aalborg Industries After Sales and deals with operation of steam and heating equipment. Ideas and suggestions for topics are most welcome. Aalborg Industries A/S · Gasvaerksvej 24 · P.O. Box 844 · 9100 Aalborg · Denmark Phone: +45 9930 4000 · Telefax: +45 9810 2233 · E-mail: [email protected] For world-wide After Sales addresses, ect., please check http://www.aalborg-industries.com

Keep your feedwater steaming hot Corroding salts, gases and oxygen occur in boiler water but can be kept in check if the temperature is kept sufficiently high. The Feedcon steam system is an efficient solution.

Temperature control

Temperature control Condenser

Steam

Water - friend or foe

The enemy within

Oxygen in the feedwater is the

The majority of ships run with

Untreated water is never pure. It

major cause of corrosion in boilers.

ineffective or improperly operated

contains a cocktail of salts and gases. The oxygen can, however, be

water treatment systems. This leads

Salts, if not removed or altered by

removed by keeping the feedwater

to:

chemicals and water softening

temperature above 85ºC.

Extensive High

damage to boilers

repair costs

Dramatic

treatment, cause scaling on boiler heat transfer surfaces.

reduction in boiler life

Fighting oxygen Thermal deaeration will remove up

Carbon dioxide gas will combine

to 75 percent of the unwanted oxy-

A proper system for boiler feed-

with water to form carbonic acid,

gen in feedwater. Chemical oxygen

water will maintain normal boiler

which attacks the boiler and the

scavengers can absorb the remain-

life expectancy up to 30 years.

condensation system.

ing oxygen.

Fighting carbon dioxide

ally offered together with new

Heating of boiler feedwater can

boiler plants but generally decided

keep the carbon dioxide in check.

against by the shipyards, much to

At a temperature of 85 to 90°C,

the regret of shipowners and ship

carbon dioxide is in its steam phase,

managers later. The Feedcon system

and the gas is harmless in this state.

is, however, easy to install and

The temperature must be maintain-

operate.

ed, or corrosion will be triggered

A Feedcon steam injection system

by the changes in the carbon diox-

in a closed, vented feedwater tank

ide contents. Alkaline boiler water

will ensure that the feedwater tem-

SUNROD™ pin tube damaged by

and chemical treatment can help

perature is maintained at a mini-

oxygen corrosion (pittings).

neutralise the effects of the gas as

mum of 85°C, thus preventing oxy-

well as handle the salt problem.

gen corrosion.

being returned to the cascade tank or hotwell tank. This means that

Aalborg’s money-saving Feedcon system

A system for controlling conden-

more steam has to be injected to

sate temperatures also solves the

maintain the temperature. The

Aalborg Industries has a highly

related and costly problem in con-

Feedcon system prevents this waste

effective solution to solving feed-

densate water from the system

of energy and saves the ship opera-

water problems. The system is usu-

which is often super-cooled before

tors unnecessary costs.

Keep your feedwater steaming hot and you will gain A

longer boiler life

Lower

operating costs

Higher

steam output

Less

maintenance

Oxygen content (ppm)

Lower

consumption of chemicals

At atmospheric pressure

Water temperature (°C)

Aalborg Solutions is published by Aalborg Industries After Sales and deals with operation of steam and heating equipment. Ideas and suggestions for topics are most welcome. Aalborg Industries A/S · Gasvaerksvej 24 · P.O. Box 844 · 9100 Aalborg · Denmark Phone: +45 9930 4000 · Telefax: +45 9810 2233 · E-mail: [email protected] For world-wide After Sales addresses, ect., please check http://www.aalborg-industries.com