Seader, Henley - (04) Separation Process Principles, 2nd Ed_-split-merge.pdf 4l4l34

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3i3n4

Overview 26281t

& View Seader, Henley - (04) Separation Process Principles, 2nd Ed_-split-merge.pdf as PDF for free.

More details 6y5l6z

- Words: 5,326

- Pages: 25

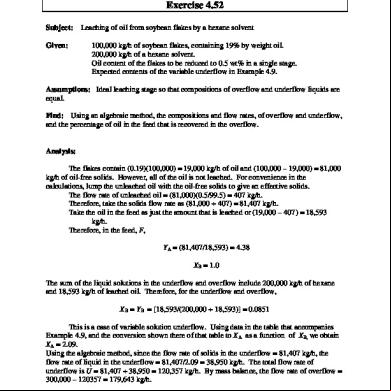

Exercise 4.52 Subject: Given:

Leaching of oil from soybean flakes by a hexane solvent 100,000 kg/h of soybean flakes, containing 19% by weight oil. 200,000 kg/h of a hexane solvent. Oil content of the flakes to be reduced to 0.5 wt% in a single stage. Expected contents of the variable underflow in Example 4.9.

Assumptions: Ideal leaching stage so that compositions of overflow and underflow liquids are equal. Find: Using an algebraic method, the compositions and flow rates, of overflow and underflow, and the percentage of oil in the feed that is recovered in the overflow. Analysis: The flakes contain (0.19)(100,000) = 19,000 kg/h of oil and (100,000 – 19,000) = 81,000 kg/h of oil-free solids. However, all of the oil is not leached. For convenience in the calculations, lump the unleached oil with the oil-free solids to give an effective solids. The flow rate of unleached oil = (81,000)(0.5/99.5) = 407 kg/h. Therefore, take the solids flow rate as (81,000 + 407) = 81,407 kg/h. Take the oil in the feed as just the amount that is leached or (19,000 – 407) = 18,593 kg/h. Therefore, in the feed, F, YA = (81,407/18,593) = 4.38 XB = 1.0 The sum of the liquid solutions in the underflow and overflow include 200,000 kg/h of hexane and 18,593 kg/h of leached oil. Therefore, for the underflow and overflow, XB = YB = [18,593/(200,000 + 18,593)] = 0.0851 This is a case of variable solution underflow. Using data in the table that accompanies Example 4.9, and the conversion shown there of that table to XA as a function of XB, we obtain XA = 2.09. Using the algebraic method, since the flow rate of solids in the underflow = 81,407 kg/h, the flow rate of liquid in the underflow = 81,407/2.09 = 38,950 kg/h. The total flow rate of underflow is U = 81,407 + 38,950 = 120,357 kg/h. By mass balance, the flow rate of overflow = 300,000 – 120357 = 179,643 kg/h.

Exercise 4.52 (continued) Now compute the compositions of the underflow and overflow. In the overflow, with XB = 0.0851, the mass fractions of solute B and solvent C are, respectively, 0.0851 and (1 – 0.0851) = 0.9149. In the underflow, using XA = 2.09 and XB = 0.0851, the mass fractions of solids, B, and C, are, respectively, [2.09/(1 + 2.09)] = 0.676, 0.0851(1 – 0.676) = 0.0276, and (1 – 0.676 – 0.0276) = 0.2964. From above, the oil flow rate in the feed is 19,000 kg/h. The oil flow rate in the overflow = YBV = 0.0851(179,643) = 15,288 kg/h. Thus, the percentage of the oil in the feed that is recovered in the overflow = 15,288/19,000 = 0.805 or 80.5%.

Exercise 4.53 Subject:

Leaching of Na2CO3 from a solid by water.

Given: Lo = 3,750 kg/h of a solid containing 1,350 kg/h Na2CO3, ed with So = 4,000 kg/h of water. Assumptions: Ideal leaching stage so that compositions of overflow and underflow liquid are equal. Underflow contains 40 wt% water on a solute-free basis. Find: Compositions and flow rates, L1 and S1, respectively, of overflow and underflow. Analysis: Let x = mass fraction of Na2CO3 (solute). Lo + So = 3,750 + 4,000 = 7,750 = L1 + S1 (a) Total balance: Na2CO3 balance: x Lo Lo = 1,350 = x L1 L1 + xS1 S1 Insoluble solids balance: (3,750 − 1,350) = 2,400 = (1 − 0.40) 1 − xS1 S1 = 0.60 1 − xS1 S1 Equilibrium:

x L1 =

xS1 S1 S1 − (0.60) 1 − xS1 S1

=

(1) (2) (3)

xS1

(4)

0.4 + 0.6 xS1

Eqs. (1) to (4) can be reduced to one quadratic equation in xS1 . Solving,

xS1 = 01189 . ; x L1 = 0.2523 ; S1 = 4,540 kg / h ; and L1 = 3,210 kg / h

The material balance may be summarized as follows:

Component Insoluble oxide Na2CO3 Water Total

Lo , Solids, kg/h 2.400 1,350 0 3,750

So , Solvent, kg/h 0 0 4,000 4,000

L1 , Overflow, kg/h 0 810 2,400 3,210

S1 , Underflow, kg/h 2,400 540 1,600 4,540

The % extraction of Na2CO3 = 810/1,350 x 100% = 60%

Exercise 4.54 Subject:

Leaching of Na2CO3 from a solid by water.

Given: Lo = 3,750 kg/h of a solid containing 1,350 kg/h Na2CO3, ed with So = 4,000 kg/h of water. Assumptions: Ideal leaching stage so that compositions of overflow and underflow liquid are equal. Underflow contains 40 wt% water on a solute-free (dissolved Na2CO3-free) basis. Only 80% of the Na2CO3 is dissolved. Find: Compositions and flow rates, L1 and S1, respectively, of overflow and underflow. Analysis: Because only 80% of the Na2CO3 is dissolved, the underflow will contain (3,750 1,350) = 2,400 kg/h of insoluble oxide plus (0.20)(1,350) = 270 kg/h of solid Na2CO3 or a total of 2,670 kg/h of total solids. Let: V = kg/h of overflow L = kg/h of liquid in the underflow. Total underflow = L + 2,670 kg/h y = mass fraction of dissolved Na2CO3 in overflow or underflow liquid (equilibrium) Total mass balance: Na2CO3 mass balance:

Lo + So = 4,000 + 3,750 = 7,750 = V + L + 2,670 1,350 = 270 + y(V + L)

(1) (2)

Solving Eqs. (1) and (2), V + L = 5,080 kg/h and y = 0.2126 Flow rate of underflow on a solute-free basis = (1 - y)L + 2,670 = 0.7874 L + 2,670 kg/h Therefore the flow rate of water in the underflow = 0.40(0.7874 L + 2,670) Water mass balance:

4,000 = (1 - 0.2126)V + 0.40(0.7874 L + 2,670)

Solving linear Eqs. (1) and (3), L = 2,260 kg/h and V = 2,820 kg/h The material balance may be summarized as follows:

Component Insoluble oxide Insoluble Na2CO3 Soluble Na2CO3 Water Total

Lo , Solids, kg/h 2.400 1,350 0 3,750

So , Solvent, kg/h 0 0 0 4,000 4,000

The % extraction of Na2CO3 = 600/1,350 x 100% = 44.4%

Overflow, kg/h 0 0 600 2,220 2,820

Underflow, kg/h 2,400 270 480 1,780 4,930

(3)

Exercise 4.55 Subject: Crystallization from a mixture of benzene and naphthalene. Given: 6,000 lb/h of 40 wt% benzene and 60 wt% naphthalene in liquid state at 50oC, which is cooled to 15oC. Assumptions: Equilibrium at 15oC. Equilibrium phase diagram of Fig. 4.23. Find: Flow rates and compositions of crystals and mother liquor. Analysis: The feed is (0.60)(6,000) = 3,600 lb/h of naphthalene and 2,400 lb/h of benzene. In the figure below: A is the feed solution at 50oC. It lies in the homogeneous solution region. C is the feed solution at 15oC. It now lies in the two-phase region and separates into naphthalene crystals at D and mother liquor at B. From the diagram, the mother liquor at 15oC contains 31.5wt% naphthalene and, therefore, 68.5 wt% benzene. Because all of the benzene is in the mother liquor, the mother liquor flow rate is 2,400/(0.685) = 3,500 lb/h. Therefore, the naphthalene crystals flow rate is 6,000 - 3,500 = 2,500 lb/h. The % crystallization of naphthalene is 2,500/3,600 x 100% = 69.4%.

Exercise 4.56 Subject: Crystallization from a mixture of benzene and naphthalene. Given: 6,000 lb/h of 40 wt% benzene and 60 wt% naphthalene in liquid state at 50oC to be cooled to obtain crystals of naphthalene. Assumptions: Equilibrium upon cooling, using phase diagram of Fig. 4.23. Find: Temperature necessary to crystallize 80% of the naphthalene. Flow rates and compositions of crystals and mother liquor. Analyze: The feed is (0.60)(6,000) = 3,600 lb/h of naphthalene and 2,400 lb/h of benzene. If 80% of the naphthalene is crystallized, the crystals flow rate will be (0.8)(3,600) = 2,880 lb/h. This leaves (3,600 - 2,880) = 720 lb/h of naphthalene in the mother liquor, with 2,400 lb/h of benzene. The total flow rate of mother liquor is 720 + 2,400 = 3,120 lb/h. Therefore, the naphthalene concentration in the mother liquor is 720/3,120 x 100% = 23 wt%. In the figure below, A is the feed solution at 50oC. It lies in the homogeneous solution region C is the feed solution in the two-phase region, which separates into naphthalene crystals at D and mother liquor at B, with the 23 wt% solubility. It is seen that a temperature of 3oC is needed to achieve a naphthalene solubility of 23 wt%.

Exercise 4.57 Subject: Crystallization from a mixture of benzene and naphthalene. Given: 10,000 kg/h of 90 wt% benzene and 10 wt% naphthalene in liquid state at 30oC to be cooled to 0oC to obtain crystals. Assumptions: Equilibrium upon cooling to 0oC, using phase diagram of Fig. 4.23. Find: Flow rates and compositions of crystals and mother liquor. Analyze: The feed is (0.10)(10,000) = 1,000 kg/h of naphthalene and 9,000 kg/h of benzene. In the figure below: A is the feed solution at 30oC. It lies in the homogeneous solution region. C is the feed solution at 0oC. It now lies in the two-phase region and separates into benzene crystals at B and mother liquor at D. From the diagram, the mother liquor at 0oC contains 15 wt% naphthalene and, therefore, 85 wt% benzene. Because all of the naphthalene is in the mother liquor, the mother liquor flow rate is 1,000/(0.15) = 6,667 kg/h. Therefore, the benzene crystals flow rate is 10,000 - 6,667 = 3,333 kg/h. The % crystallization of benzene is 3,333/9,000 x 100% = 37.0%.

Exercise 4.58 Subject: Crystallization of Na2SO4 from an aqueous solution by cooling. Given: 1,000 lb/h of Na2SO4 dissolved in 4,000 lb/h of H2O at 50oC. Assumptions: Equilibrium according to phase diagram of Fig. 4.24. Find: Temperature at which crystallization begins. Temperature to obtain 50% crystallization of the sulfate. Hydrate form of the crystals. Analysis: In the diagram below, the feed of 20 wt% sulfate, at point A, is in the homogeneous solution region at 50oC. Crystallization begins at point B, corresponding to a temperature of 24oC. As the temperature is lowered further, crystals of the decahydrate, Na 2SO 4 ⋅10H 2 O form. For 50% crystallization of Na2SO4 , must crystallize 0.5(1,000) = 500 lb/h. For the decahydrate, with molecular weights of 18 for water and 142 for the sulfate, the crystals contain: (10)(18) = 634 lb/h or water of crystallization 142 Therefore, the total flow rate of crystals = 500 + 634 = 1,134 lb/h. This leaves 4,000 - 634 = 3,366 lb/h of water and 1,000 - 500 = 500 lb/h of sulfate in the mother liquor. The total flow rate of mother liquor is 3,366 + 500 = 3,866 lb/h. Thus, the concentration of sulfate in the mother liquor = 500/3,866 x 100% = 12.9 wt% Na2SO4. From the diagram below, the required temperature for this concentration at C in the mother liquor is 18oC. 500

Exercise 4.59 Subject: Dissolving crystals of Na2SO4 with water. Given: 500 kg of Na 2SO 4 ⋅10H 2 O crystals and 500 kg of Na2SO4 crystals at 20oC. Assumptions: Equilibrium according to phase diagram of Fig. 4.24. Find: Amount of water to dissolve the crystals at 20oC. Analysis: From Fig. 4.24, the solubility of Na2SO4 in water at 20oC is 15 wt% Na2SO4. Molecular weight of Na2SO4 = 142. Molecular weight of Na 2SO 4 ⋅10H 2 O = 322. Therefore, the kg of Na2SO4 in Na 2SO 4 ⋅10H 2 O = 500(142/322) = 220 kg. The water in Na 2SO 4 ⋅10H 2 O = 500 - 220 = 280 kg. Total Na2SO4 in the crystals = 500 + 220 = 720 kg. Therefore, need a total of 720(85/15) = 4,080 kg water. Additional water needed = 4,080 - 280 = 3,800 kg.

Exercise 4.60 Subject: Adsorption of phenol (B) from an aqueous solution at 20oC with activated carbon. Given: One liter of aqueous solution containing 0.01 mol phenol. Freundlich isotherm equation for adsorption of phenol from aqueous solution by activated carbon at 20oC. Assumptions: Attainment of equilibrium. Find: Grams of activated carbon for (a) 75%, (b) 90%, and (c) 98% adsorption of phenol Analysis: At equilibrium, Eq. (1) in Example 4.12 is: q B* = 2.16cB0.233 (1) * where, q B = mmol phenol adsorbed/g carbon cB = mmol phenol in solution/liter solution For each case, cB = 0.01(1,000 mmol/mol)(1-fraction adsorbed) mmol adsorbed = 0.01(1,000 mmol/mol)(1 liter)(fraction adsorbed) g activated carbon needed = mmol adsorbed/ q B* Using these equations, the results are as follows: Case g activated cB at equilib, mmol phenol q B* , adsorbed carbon mmol/L mmol/g (a) 75% adsorbed 2.5 7.5 2.67 2.81 (b) 90% adsorbed 1.0 9.0 2.16 4.17 (c) 98% adsorbed 0.2 9.8 1.48 6.62

Exercise 4.61 Subject: Adsorption of a colored substance (B) from an oil by clay particles at 25oC. Given: Oil with a color index of 200 units/100 kg oil. Adsorption equilibrium data Assumptions: One adsorption equilibrium . Find: (a) Freundlich equation for the adsorption equilibrium data. (b) kg clay to reduce color index to 20 units/100 kg oil for 500 kg of oil Analysis: (a) From Eq. (4-30), the Freundlich equation is q B* = AcB1/ n , where here, q B* = color units/100 kg clay and cB = color units/100 kg oil By nonlinear regression of the data, A = 0.6733 and (1/n) = 0.5090 The linearized form of the Freundlich equation is log q B* = log A + (1 / n) log cB By linear regression of the data with the linearized form, A = 0.6853, (1/n) = 0.5050 The two results are close and both fit the data quite well. Use the nonlinear regression result: qB* = 0.6733cB0.509 (b)

(1)

Q = 500 kg oil S = kg clay cB(F ) = 200 units/kg oil Need, at equilibrium, cB = 20 units/kg oil From Eq. (1), qB* = 0.6733(20) 0.509 = 3.09 units/kg clay

Apply Eq. (4-29 for a material balance on the color units: q B* = 3.09 = −

Q Q 500 500 cB + cB( F ) = − (20) + (200) S S S S

Solving Eq. (2), S = 29,100 kg of clay

(2)

Exercise 4.45 Subject: Comparison of solvents for single-equilibrium-stage liquid-liquid extraction. Given: Feed, F = 13,500 kg/h of 8 wt% acetic acid (B) in water (A) at 25oC. Four solvents (C), each with a different distribution coefficient, KC, in mass fractions, xB, for acetic acid, as given in the table below, according to Eq. (2-20), where (1) is the extract of flow rate E and (2) is the raffinate of flow rate R, where for a single equilibrium stage, the raffinate is to contain only 1 wt% B

K DB = xB( E ) / xB( R )

(1)

Assumptions: Water is insoluble in the solvent and the solvent is insoluble in water. Find: The kg/h, S, of each solvent required. Analysis: In Eq. (1), xB(R ) = 0.01. Therefore, xB(E ) = 0.01 K DB A total material balance gives:

(2)

F = 13,500 = E + R - S

(3)

An acetic acid material balance gives: xB( F ) F = (0.08)(13,500) = 1,080 = xB( E ) E + xB( R ) R = xB( E ) E + 0.01R

(4)

92 wt% of the feed is water, or (0.92)(13,500) = 12,420 kg/h. Since all of the water appears in the raffinate, which is 99 wt% water, R = 12,420/0.99 = 12,546 kg/h. Eq. (3) becomes: S = E - 954 (5) and Eq. (4) becomes:

xB(E ) E = 954.5

(6)

Eqs. (2), (5), (6) are three equations in three unknowns: S, E, and xB(E ) . For each solvent, solve Eq. (2) for xB(E ) . Solve (6) for E. Solve (5) for S. The results are:

Solvent Methyl acetate Isopropyl ether Heptadecanol Chloroform

KD 1.273 0.429 0.312 0.178

xB(E ) 0.01273 0.00429 0.00312 0.00178

E, kg/h

S, kg/h

74.984 222,500 305,940 536,260

74,030 221,500 305,000 535,300

Although methyl acetate is the best solvent, the solvent rates required are very large. To reduce the solvent rate, use a countercurrent, multiple-stage system.

Exercise 4.46 Subject:

Liquid-liquid extraction of ethylene glycol from water by furfural with one stage.

Given: Feed, F = 45 kg, of 30 wt% ethylene glycol (B) and 70 wt% water (A). Phase equilibrium diagrams of Fig. 4.14a and 4.14e for 25oC. Find: (a) Minimum amount of solvent. (b) Maximum amount of solvent. (c) % glycol extraction and amounts of solvent-free extract and raffinate for 45 kg solvent. (d) Maximum possible glycol purity in extract. Maximum purity of water in raffinate. Analysis: For a single stage, all mixtures of feed, F, and solvent, S, lie on a straight line between these two points as shown in the following ternary diagram of Fig. 4.14a. (a) The minimum amount of solvent corresponds to the maximum solubility of the solvent in the feed. This is point M1 in the diagram below. By the inverse lever arm rule, S/F = 0.097. Therefore, Smin = 0.0972(45) = 4.4 kg. In this case, no extract is obtained. (b) The maximum amount of solvent corresponds to maximum solubility of the feed in the solvent. This is point M2 in the diagram below. By the inverse lever arm rule, S/F = 11.15. Thus, Smax = 11.2(45) = 504 kg. In this case, no raffinate is obtained.

Exercise 4.46 (continued) Analysis: (continued) (c) With 45 kg of solvent, S/F = 1. Therefore, the mixing point, M3 is at the mid point between F and S in the diagram below. A tie line drawn through point M3 determines the raffinate, R, and the extract, E. By total material balance, R + E = F + S = 45 + 45 = 90. By the inverse lever arm rule, R/E = 0.61. Combining these equations gives: E = 55.9 kg, R = 34.1 kg. From the diagram, the composition of the extract is: 19 wt% B, 76 wt % C, and 5 wt% A. Therefore, the extract contains (0.19)(55.9) = 10.62 kg B. The composition of the raffinate is 8 wt% B, 84 wt% A, and 8 wt% C. The % extraction of glycol (B) = 10.62/[(0.30)(45)] x 100% = 78.7%. The amount of solvent-free extract = (55.9)(1 - 0.76) = 13.4 kg. The amount of solvent-free raffinate = (34.1)(1 - 0.08) = 31.4 kg.

Exercise 4.46 (continued) Analysis: (continued) (d) The maximum possible glycol purity in the extract occurs when the minimum amount of solvent is used, as discussed in part (a), giving raffinate R1. In this case, have say just one drop of extract, corresponding to point E1, which connects to R1 by a tie line in the diagram below. At point E1, have 48 wt% glycol. The maximum purity of water in the raffinate occurs when the maximum amount of solvent is used, as discussed in part (b), giving extract E2. In this case, have say just one drop of raffinate, corresponding to point R2, which connects to E2 by a tie line in the diagram below. At point R2, have 90 wt% water.

Exercise 4.47 Subject: Representation of the composition of a ternary mixture on a triangular diagram. Given: A triangular diagram where each vertex represents a pure component. Assumptions: Consider the case of an equilateral triangular diagram. Prove: The composition of any point inside the triangle is proportional to the length of the respective perpendicular drawn from the point to the side of the triangle opposite the vertex in question. Analysis: In the triangular diagram below, the pure components are E, R, and S. A mixture of these components is represented by the point M. For the equilateral triangle shown, the sum of the lengths of the three perpendiculars drawn from an interior point, such as M, to the three sides equals the altitude, is the same length from each side. Therefore, divide each altitude into 100 divisions and number these divisions starting with 0 at the base to 100 at the apex. Thus, if the divisions represent wt% (or mol%), the sum of the perpendiculars equals 100%. In the diagram below, each division is 10%. The perpendicular s measures 28% and is the composition of S. The perpendicular r measures 18% and is the composition of R. The perpendicular e measures 54% and is the composition of E. This proof is extended to a triangle of any shape on pages 11 to 18 of "Chemical Process Principles, Part I" by Hougen, Watson, and Ragatz.

Exercise 4.48 Subject:

Liquid-liquid extraction of acetic acid from chloroform by water at 18oC and 1 atm.

Given: Equilibrium data for the ternary mixture Assumptions: Equilibrium stages. Find: (a) Compositions and weights of raffinate and extract when 45 kg of a 35 wt% chloroform (C) and 65 wt% acetic acid (A) feed mixture (F) is extracted with 22.75 kg of water (S) in a single-stage extraction. (b) Compositions and weights of raffinate and extract if the raffinate from part (a) is extracted again with half its weight of water. (c) Composition of the raffinate from part (b) if all the water is removed from it. Use a right-triangle diagram of the equilibrium data, which is easily produced Analysis: with a spreadsheet. (a) In the diagram on the next page, the feed and solvent are represented by points F and S, respectively. The mixing point is M1, which is the sum of the feed and solvent (67.75 kg) with an overall composition of 33.58 wt% S, 23.25 wt% C, and 43.17 wt% A. A tie line ing through point M1 locates, on the equilibrium curve, the extract E1 and the raffinate R1. If the inverse lever arm rule is used to obtain E1 and R1, and their compositions are read from the diagram, the following results are obtained: Feed Solvent Extract Raffinate F S E1 R1 Amount, kg 45 22.75 55 12.75 Composition, wt%: Chloroform 35 0 11.5 74.5 Acetic acid 65 0 48.0 22.0 Water 0 100 40.5 3.5 (b) If R1 is mixed with half its weight of solvent (6.375 kg), the mixing point is M2, shown in the diagram on the next page, with an overall composition of 14.6 wt% A, 49.7 wt% C, and 35.7 wt% S. . A tie line ing through point M2 locates, on the equilibrium curve, the extract E2 and the raffinate R2. If the inverse lever arm rule is used to obtain E2 and R2, and their compositions are read from the diagram, the following results are obtained: Feed Solvent Extract Raffinate Water-free (R1) S E2 R2 Raffinate Amount, kg 12.75 6.375 8.895 10.23 10.10 Composition, wt%: Chloroform 74.5 0 1.0 91.0 93.2 Acetic acid 22.0 0 24.0 6.7 6.8 Water 3.5 100 74.9 1.3 0.0 (c) The water-free raffinate is included in the above table.

Exercise 4.48 (continued)

Exercise 4.49 Subject:

L-L extraction of acetic acid from water by isopropyl ether at 25oC and 1 atm.

Given: Equilibrium data for the ternary mixture Assumptions: Equilibrium stages. Find: (a) Compositions and weights of raffinate and extract when 100 kg of a 30 wt% acetic acid (A) and 70 wt% water (W) feed mixture (F) is extracted with 120 kg of isopropyl ether (E) in a single-stage extraction. Weight % of A in the extract if E is removed. (b) Compositions and weights of raffinate and extract if 52 kg of A and 48 kg of W are ed with 40 kg of E Analysis: Use a right-triangle diagram of the equilibrium data, which is easily produced with a spreadsheet. (a) In the diagram on the next page, the feed and solvent are represented by points F1 and S, respectively. The mixing point is M1, which is the sum of the feed and solvent (220 kg) with an overall composition of 13.6 wt% A, 31.8 wt% W, and 54.6 wt% E. A tie line ing through point M1 locates, on the equilibrium curve, the extract E1 and the raffinate R1. If the inverse lever arm rule is used to obtain E1 and R1, and their compositions are read from the diagram, the following results are obtained, including the amount and composition of the ether-free extract. Feed Solvent Extract Raffinate Ether-free F1 S E1 R1 Extract Amount, kg 100 120 133.4 86.6 16.1 Composition, wt%: Water 70 0 2.9 76.3 24.2 Acetic acid 30 0 9.1 20.6 75.8 Isopropyl ether 0 100 88.0 3.1 0.0 (b) In the diagram on the next page, the feed and solvent are represented by points F2 and S, respectively. The mixing point is M2, which is the sum of the feed and solvent (140 kg) with an overall composition of 37.1 wt% A, 34.3 wt% W, and 28.6 wt% E. A tie line ing through point M2 locates, on the equilibrium curve, the extract E2 and the raffinate R2. If the inverse lever arm rule is used to obtain E2 and R, and their compositions are read from the diagram, the following results are obtained: Feed Solvent Extract Raffinate F2 S E2 R2 Amount, kg 100 40 55.0 85.0 Composition, wt%: Water 48 0 9.3 50.5 Acetic acid 52 0 28.9 42.5 Isopropyl ether 0 100 61.8 7.0

Exercise 4.49 (continued)

Exercise 4.1 Subject: Degrees of freedom analysis for a three-phase equilibrium stage. Given: Equilibrium stage of Figure 4.35, with two feeds (one vapor, one liquid), vapor entering from stage below, liquid entering from stage above, three exiting streams (one vapor, two liquid), and heat transfer. Assumptions: Equilibrium stage Find: (a) (b) (c) (d) Analysis:

List and count of variables. List and count of equations. Number of degrees of freedom. List of reasonable set of design variables. (a) With 4 streams in and 3 streams out, and heat transfer, Number of variables = NV = 7(C+3) + 1 = 7C + 22

The variables are 7 total flow rates, 7 temperatures, 7 pressures, 1 heat transfer rate and C mole fractions for each of the 7 streams. (b) The equations are: C Component material balances 1 Energy balance 2 Pressure identity equations for the 3 exiting streams 2 Temperature identity equations for the 3 exiting streams 7 Mole fraction sums (one for each stream) y y 2C Phase equilibrium equations: KiI = iI and KiII = IIi xi xi Total number of equations = NE = 3C + 12 (c) Degrees of freedom = ND= NV - NE = (7C + 22) - (3C + 12) = 4C +10 (d) A possible set of specifications is: For each entering stream: Total flow rate, temperature, pressure, and C-1 mole fractions, which totals 4(C + 2) = 4C + 8 For the remaining 2 variables, choose any combination of Q, temperature of one of the three exiting streams, and/or pressure of one of the three exiting streams.

Exercise 4.2 Subject: Determination of uniqueness of three different operations. Given: (a) An adiabatic equilibrium stage with known vapor and liquid feed streams, and known stage temperature and pressure. (b) Same as (a), except that stage is not adiabatic. (c) Partial condenser using cooling water, with known vapor feed (except for flow rate), outlet pressure, and inlet cooling water flow rate. Assumptions: Exiting streams in equilibrium. Find:

(a) Whether composition and amounts of exiting vapor and liquid can be computed. (b) Same as part (a). (c) Whether cooling water rate can be computed.

Analysis: (a) With two steams in and two out, number of variables = NV = 4(C + 3) = 4C + 12 Equations are: C Component material balances 1 Energy balance 1 Pressure identity for 2 exiting streams 1 Temperature identity for 2 exiting streams 4 Mole fraction sums for 4 streams C Phase equilibrium equations Therefore, number of equations = NE =2C + 7 Degrees of freedom = ND= NV - NE = (4C + 12) - (2C + 7) = 2C +5 Given specifications are: 2C + 4 variables for the two feed streams. Only one specification left. Therefore can not specify both T and P for exiting streams. (b) If stage in part (a) is not adiabatic, add Q as a variable to give NV = 4C + 13. The number of equations stays the same, i. e. NE =2C + 7. Thus, have one additional degree of freedom, giving, ND= NV - NE = 2C +6. Can now specify both T and P for exiting streams. (c) First, consider just the partial condensation of the vapor into two exiting streams by heat transfer, Q, without considering the cooling water. For three streams, NV =3(C + 3) + 1 (for Q) = 3C +10. Equations are: C Component material balances 1 Energy balance 1 Pressure identity for 2 exiting streams 1 Temperature identity for 2 exiting streams 3 Mole fraction sums for 3 streams C Phase equilibrium equations Therefore, NE = 2C + 6 and ND = NV - NE = C + 4

Exercise 4.2 (continued) Analysis: (c) (continued) Specified for the feed vapor are only C + 1 variables, because the feed rate is not specified. Also the outlet pressure of the condenser is specified. This give C + 2. We are short two variables from being able to compute Q. An energy balance on the cooling water gives: Q = m Tout − Tin

But only Tin is given. Thus, with Q unknown and Tout not given, we are three variable short of being able to compute the water rate, m. Thus, the problem can not be solved uniquely. We could solve it if the vapor feed rate, the outlet temperature of the partial condensate, and the cooling water outlet temperature were specified.

Exercise 4.3 Subject: Degrees of freedom analysis for an adiabatic, two-phase flash. Given: Continuous, adiabatic flash of one feed into vapor and liquid products Assumptions: Exiting streams are in equilibrium Find: (a) (b) (c) (d) (e) Analysis:

Number of variables. All equations relating variables. Number of equations. Number of degrees of freedom Preferred specifications (a) Variables are those appearing in Figure 4.36 N V = 3C + 9 (b) C Component material balances 1 Energy balance 1 Pressure identity for two exiting streams 1 Temperature identity for two exiting streams 3 Mole fraction sums for three streams C Vapor-liquid equilibrium equations (c) NE = 2C + 6 (d) ND = NV - NE = (3C + 9) - (2C + 6) = C + 3 (e) Specify the feed completely ( feed rate, temperature, pressure and C - 1 mole fractions) plus exiting pressure.

Exercise 4.4 Subject: Degrees of freedom analysis for a non-adiabatic three-phase flash. Given: Continuous, non-adiabatic flash of a liquid feed to produce a vapor and two liquid phases as shown in Figure 4.33. Assumptions: The three exiting phases are in equilibrium. Find: Number of degrees of freedom. Analysis: The variables are the heat transfer rate and four each of stream flow rates, temperatures, pressures, and C mole fractions. Thus, NV = 4C + 13. The equations are: C Component material balances 1 Energy balance 2 Pressure identities for three exiting streams 2 Temperature identities for three exiting streams 4 Mole fraction sums for four streams 2C Phase equilibrium relations: KiI = yi / xiI and KiII = yi / xiII Therefore, NE = 3C + 9 Number of degrees of freedom = ND = NV - ND = (4C + 13) - (3C + 9) = C + 4

Exercise 4.5 Subject: Application of Gibbs phase rule to seven-phase system of Figure 4.31. Given: One gas and six liquid phases in equilibrium. Assumptions: Gas phase includes N2 , O2 , and argon. Find: Number of degrees of freedom by Gibbs phase rule. Possible set of specifications to fix system. Analysis: From Eq. (4-1), Number of degrees of freedom = C - number phases + 2 Number of components = 9 (N2 , O2 , argon, n-hexane, aniline, water, phosphorus, gallium, and mercury. Number of phases = 7 Number of degrees of freedom = 9 - 7 + 2 = 4 Specify T, P, and mole fractions of argon and oxygen in the air.

Leaching of oil from soybean flakes by a hexane solvent 100,000 kg/h of soybean flakes, containing 19% by weight oil. 200,000 kg/h of a hexane solvent. Oil content of the flakes to be reduced to 0.5 wt% in a single stage. Expected contents of the variable underflow in Example 4.9.

Assumptions: Ideal leaching stage so that compositions of overflow and underflow liquids are equal. Find: Using an algebraic method, the compositions and flow rates, of overflow and underflow, and the percentage of oil in the feed that is recovered in the overflow. Analysis: The flakes contain (0.19)(100,000) = 19,000 kg/h of oil and (100,000 – 19,000) = 81,000 kg/h of oil-free solids. However, all of the oil is not leached. For convenience in the calculations, lump the unleached oil with the oil-free solids to give an effective solids. The flow rate of unleached oil = (81,000)(0.5/99.5) = 407 kg/h. Therefore, take the solids flow rate as (81,000 + 407) = 81,407 kg/h. Take the oil in the feed as just the amount that is leached or (19,000 – 407) = 18,593 kg/h. Therefore, in the feed, F, YA = (81,407/18,593) = 4.38 XB = 1.0 The sum of the liquid solutions in the underflow and overflow include 200,000 kg/h of hexane and 18,593 kg/h of leached oil. Therefore, for the underflow and overflow, XB = YB = [18,593/(200,000 + 18,593)] = 0.0851 This is a case of variable solution underflow. Using data in the table that accompanies Example 4.9, and the conversion shown there of that table to XA as a function of XB, we obtain XA = 2.09. Using the algebraic method, since the flow rate of solids in the underflow = 81,407 kg/h, the flow rate of liquid in the underflow = 81,407/2.09 = 38,950 kg/h. The total flow rate of underflow is U = 81,407 + 38,950 = 120,357 kg/h. By mass balance, the flow rate of overflow = 300,000 – 120357 = 179,643 kg/h.

Exercise 4.52 (continued) Now compute the compositions of the underflow and overflow. In the overflow, with XB = 0.0851, the mass fractions of solute B and solvent C are, respectively, 0.0851 and (1 – 0.0851) = 0.9149. In the underflow, using XA = 2.09 and XB = 0.0851, the mass fractions of solids, B, and C, are, respectively, [2.09/(1 + 2.09)] = 0.676, 0.0851(1 – 0.676) = 0.0276, and (1 – 0.676 – 0.0276) = 0.2964. From above, the oil flow rate in the feed is 19,000 kg/h. The oil flow rate in the overflow = YBV = 0.0851(179,643) = 15,288 kg/h. Thus, the percentage of the oil in the feed that is recovered in the overflow = 15,288/19,000 = 0.805 or 80.5%.

Exercise 4.53 Subject:

Leaching of Na2CO3 from a solid by water.

Given: Lo = 3,750 kg/h of a solid containing 1,350 kg/h Na2CO3, ed with So = 4,000 kg/h of water. Assumptions: Ideal leaching stage so that compositions of overflow and underflow liquid are equal. Underflow contains 40 wt% water on a solute-free basis. Find: Compositions and flow rates, L1 and S1, respectively, of overflow and underflow. Analysis: Let x = mass fraction of Na2CO3 (solute). Lo + So = 3,750 + 4,000 = 7,750 = L1 + S1 (a) Total balance: Na2CO3 balance: x Lo Lo = 1,350 = x L1 L1 + xS1 S1 Insoluble solids balance: (3,750 − 1,350) = 2,400 = (1 − 0.40) 1 − xS1 S1 = 0.60 1 − xS1 S1 Equilibrium:

x L1 =

xS1 S1 S1 − (0.60) 1 − xS1 S1

=

(1) (2) (3)

xS1

(4)

0.4 + 0.6 xS1

Eqs. (1) to (4) can be reduced to one quadratic equation in xS1 . Solving,

xS1 = 01189 . ; x L1 = 0.2523 ; S1 = 4,540 kg / h ; and L1 = 3,210 kg / h

The material balance may be summarized as follows:

Component Insoluble oxide Na2CO3 Water Total

Lo , Solids, kg/h 2.400 1,350 0 3,750

So , Solvent, kg/h 0 0 4,000 4,000

L1 , Overflow, kg/h 0 810 2,400 3,210

S1 , Underflow, kg/h 2,400 540 1,600 4,540

The % extraction of Na2CO3 = 810/1,350 x 100% = 60%

Exercise 4.54 Subject:

Leaching of Na2CO3 from a solid by water.

Given: Lo = 3,750 kg/h of a solid containing 1,350 kg/h Na2CO3, ed with So = 4,000 kg/h of water. Assumptions: Ideal leaching stage so that compositions of overflow and underflow liquid are equal. Underflow contains 40 wt% water on a solute-free (dissolved Na2CO3-free) basis. Only 80% of the Na2CO3 is dissolved. Find: Compositions and flow rates, L1 and S1, respectively, of overflow and underflow. Analysis: Because only 80% of the Na2CO3 is dissolved, the underflow will contain (3,750 1,350) = 2,400 kg/h of insoluble oxide plus (0.20)(1,350) = 270 kg/h of solid Na2CO3 or a total of 2,670 kg/h of total solids. Let: V = kg/h of overflow L = kg/h of liquid in the underflow. Total underflow = L + 2,670 kg/h y = mass fraction of dissolved Na2CO3 in overflow or underflow liquid (equilibrium) Total mass balance: Na2CO3 mass balance:

Lo + So = 4,000 + 3,750 = 7,750 = V + L + 2,670 1,350 = 270 + y(V + L)

(1) (2)

Solving Eqs. (1) and (2), V + L = 5,080 kg/h and y = 0.2126 Flow rate of underflow on a solute-free basis = (1 - y)L + 2,670 = 0.7874 L + 2,670 kg/h Therefore the flow rate of water in the underflow = 0.40(0.7874 L + 2,670) Water mass balance:

4,000 = (1 - 0.2126)V + 0.40(0.7874 L + 2,670)

Solving linear Eqs. (1) and (3), L = 2,260 kg/h and V = 2,820 kg/h The material balance may be summarized as follows:

Component Insoluble oxide Insoluble Na2CO3 Soluble Na2CO3 Water Total

Lo , Solids, kg/h 2.400 1,350 0 3,750

So , Solvent, kg/h 0 0 0 4,000 4,000

The % extraction of Na2CO3 = 600/1,350 x 100% = 44.4%

Overflow, kg/h 0 0 600 2,220 2,820

Underflow, kg/h 2,400 270 480 1,780 4,930

(3)

Exercise 4.55 Subject: Crystallization from a mixture of benzene and naphthalene. Given: 6,000 lb/h of 40 wt% benzene and 60 wt% naphthalene in liquid state at 50oC, which is cooled to 15oC. Assumptions: Equilibrium at 15oC. Equilibrium phase diagram of Fig. 4.23. Find: Flow rates and compositions of crystals and mother liquor. Analysis: The feed is (0.60)(6,000) = 3,600 lb/h of naphthalene and 2,400 lb/h of benzene. In the figure below: A is the feed solution at 50oC. It lies in the homogeneous solution region. C is the feed solution at 15oC. It now lies in the two-phase region and separates into naphthalene crystals at D and mother liquor at B. From the diagram, the mother liquor at 15oC contains 31.5wt% naphthalene and, therefore, 68.5 wt% benzene. Because all of the benzene is in the mother liquor, the mother liquor flow rate is 2,400/(0.685) = 3,500 lb/h. Therefore, the naphthalene crystals flow rate is 6,000 - 3,500 = 2,500 lb/h. The % crystallization of naphthalene is 2,500/3,600 x 100% = 69.4%.

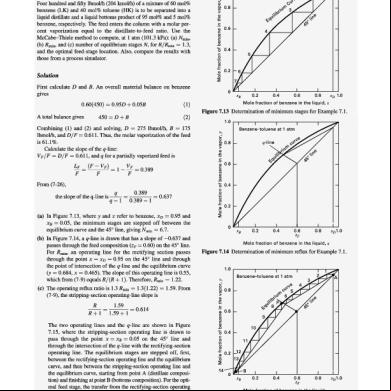

Exercise 4.56 Subject: Crystallization from a mixture of benzene and naphthalene. Given: 6,000 lb/h of 40 wt% benzene and 60 wt% naphthalene in liquid state at 50oC to be cooled to obtain crystals of naphthalene. Assumptions: Equilibrium upon cooling, using phase diagram of Fig. 4.23. Find: Temperature necessary to crystallize 80% of the naphthalene. Flow rates and compositions of crystals and mother liquor. Analyze: The feed is (0.60)(6,000) = 3,600 lb/h of naphthalene and 2,400 lb/h of benzene. If 80% of the naphthalene is crystallized, the crystals flow rate will be (0.8)(3,600) = 2,880 lb/h. This leaves (3,600 - 2,880) = 720 lb/h of naphthalene in the mother liquor, with 2,400 lb/h of benzene. The total flow rate of mother liquor is 720 + 2,400 = 3,120 lb/h. Therefore, the naphthalene concentration in the mother liquor is 720/3,120 x 100% = 23 wt%. In the figure below, A is the feed solution at 50oC. It lies in the homogeneous solution region C is the feed solution in the two-phase region, which separates into naphthalene crystals at D and mother liquor at B, with the 23 wt% solubility. It is seen that a temperature of 3oC is needed to achieve a naphthalene solubility of 23 wt%.

Exercise 4.57 Subject: Crystallization from a mixture of benzene and naphthalene. Given: 10,000 kg/h of 90 wt% benzene and 10 wt% naphthalene in liquid state at 30oC to be cooled to 0oC to obtain crystals. Assumptions: Equilibrium upon cooling to 0oC, using phase diagram of Fig. 4.23. Find: Flow rates and compositions of crystals and mother liquor. Analyze: The feed is (0.10)(10,000) = 1,000 kg/h of naphthalene and 9,000 kg/h of benzene. In the figure below: A is the feed solution at 30oC. It lies in the homogeneous solution region. C is the feed solution at 0oC. It now lies in the two-phase region and separates into benzene crystals at B and mother liquor at D. From the diagram, the mother liquor at 0oC contains 15 wt% naphthalene and, therefore, 85 wt% benzene. Because all of the naphthalene is in the mother liquor, the mother liquor flow rate is 1,000/(0.15) = 6,667 kg/h. Therefore, the benzene crystals flow rate is 10,000 - 6,667 = 3,333 kg/h. The % crystallization of benzene is 3,333/9,000 x 100% = 37.0%.

Exercise 4.58 Subject: Crystallization of Na2SO4 from an aqueous solution by cooling. Given: 1,000 lb/h of Na2SO4 dissolved in 4,000 lb/h of H2O at 50oC. Assumptions: Equilibrium according to phase diagram of Fig. 4.24. Find: Temperature at which crystallization begins. Temperature to obtain 50% crystallization of the sulfate. Hydrate form of the crystals. Analysis: In the diagram below, the feed of 20 wt% sulfate, at point A, is in the homogeneous solution region at 50oC. Crystallization begins at point B, corresponding to a temperature of 24oC. As the temperature is lowered further, crystals of the decahydrate, Na 2SO 4 ⋅10H 2 O form. For 50% crystallization of Na2SO4 , must crystallize 0.5(1,000) = 500 lb/h. For the decahydrate, with molecular weights of 18 for water and 142 for the sulfate, the crystals contain: (10)(18) = 634 lb/h or water of crystallization 142 Therefore, the total flow rate of crystals = 500 + 634 = 1,134 lb/h. This leaves 4,000 - 634 = 3,366 lb/h of water and 1,000 - 500 = 500 lb/h of sulfate in the mother liquor. The total flow rate of mother liquor is 3,366 + 500 = 3,866 lb/h. Thus, the concentration of sulfate in the mother liquor = 500/3,866 x 100% = 12.9 wt% Na2SO4. From the diagram below, the required temperature for this concentration at C in the mother liquor is 18oC. 500

Exercise 4.59 Subject: Dissolving crystals of Na2SO4 with water. Given: 500 kg of Na 2SO 4 ⋅10H 2 O crystals and 500 kg of Na2SO4 crystals at 20oC. Assumptions: Equilibrium according to phase diagram of Fig. 4.24. Find: Amount of water to dissolve the crystals at 20oC. Analysis: From Fig. 4.24, the solubility of Na2SO4 in water at 20oC is 15 wt% Na2SO4. Molecular weight of Na2SO4 = 142. Molecular weight of Na 2SO 4 ⋅10H 2 O = 322. Therefore, the kg of Na2SO4 in Na 2SO 4 ⋅10H 2 O = 500(142/322) = 220 kg. The water in Na 2SO 4 ⋅10H 2 O = 500 - 220 = 280 kg. Total Na2SO4 in the crystals = 500 + 220 = 720 kg. Therefore, need a total of 720(85/15) = 4,080 kg water. Additional water needed = 4,080 - 280 = 3,800 kg.

Exercise 4.60 Subject: Adsorption of phenol (B) from an aqueous solution at 20oC with activated carbon. Given: One liter of aqueous solution containing 0.01 mol phenol. Freundlich isotherm equation for adsorption of phenol from aqueous solution by activated carbon at 20oC. Assumptions: Attainment of equilibrium. Find: Grams of activated carbon for (a) 75%, (b) 90%, and (c) 98% adsorption of phenol Analysis: At equilibrium, Eq. (1) in Example 4.12 is: q B* = 2.16cB0.233 (1) * where, q B = mmol phenol adsorbed/g carbon cB = mmol phenol in solution/liter solution For each case, cB = 0.01(1,000 mmol/mol)(1-fraction adsorbed) mmol adsorbed = 0.01(1,000 mmol/mol)(1 liter)(fraction adsorbed) g activated carbon needed = mmol adsorbed/ q B* Using these equations, the results are as follows: Case g activated cB at equilib, mmol phenol q B* , adsorbed carbon mmol/L mmol/g (a) 75% adsorbed 2.5 7.5 2.67 2.81 (b) 90% adsorbed 1.0 9.0 2.16 4.17 (c) 98% adsorbed 0.2 9.8 1.48 6.62

Exercise 4.61 Subject: Adsorption of a colored substance (B) from an oil by clay particles at 25oC. Given: Oil with a color index of 200 units/100 kg oil. Adsorption equilibrium data Assumptions: One adsorption equilibrium . Find: (a) Freundlich equation for the adsorption equilibrium data. (b) kg clay to reduce color index to 20 units/100 kg oil for 500 kg of oil Analysis: (a) From Eq. (4-30), the Freundlich equation is q B* = AcB1/ n , where here, q B* = color units/100 kg clay and cB = color units/100 kg oil By nonlinear regression of the data, A = 0.6733 and (1/n) = 0.5090 The linearized form of the Freundlich equation is log q B* = log A + (1 / n) log cB By linear regression of the data with the linearized form, A = 0.6853, (1/n) = 0.5050 The two results are close and both fit the data quite well. Use the nonlinear regression result: qB* = 0.6733cB0.509 (b)

(1)

Q = 500 kg oil S = kg clay cB(F ) = 200 units/kg oil Need, at equilibrium, cB = 20 units/kg oil From Eq. (1), qB* = 0.6733(20) 0.509 = 3.09 units/kg clay

Apply Eq. (4-29 for a material balance on the color units: q B* = 3.09 = −

Q Q 500 500 cB + cB( F ) = − (20) + (200) S S S S

Solving Eq. (2), S = 29,100 kg of clay

(2)

Exercise 4.45 Subject: Comparison of solvents for single-equilibrium-stage liquid-liquid extraction. Given: Feed, F = 13,500 kg/h of 8 wt% acetic acid (B) in water (A) at 25oC. Four solvents (C), each with a different distribution coefficient, KC, in mass fractions, xB, for acetic acid, as given in the table below, according to Eq. (2-20), where (1) is the extract of flow rate E and (2) is the raffinate of flow rate R, where for a single equilibrium stage, the raffinate is to contain only 1 wt% B

K DB = xB( E ) / xB( R )

(1)

Assumptions: Water is insoluble in the solvent and the solvent is insoluble in water. Find: The kg/h, S, of each solvent required. Analysis: In Eq. (1), xB(R ) = 0.01. Therefore, xB(E ) = 0.01 K DB A total material balance gives:

(2)

F = 13,500 = E + R - S

(3)

An acetic acid material balance gives: xB( F ) F = (0.08)(13,500) = 1,080 = xB( E ) E + xB( R ) R = xB( E ) E + 0.01R

(4)

92 wt% of the feed is water, or (0.92)(13,500) = 12,420 kg/h. Since all of the water appears in the raffinate, which is 99 wt% water, R = 12,420/0.99 = 12,546 kg/h. Eq. (3) becomes: S = E - 954 (5) and Eq. (4) becomes:

xB(E ) E = 954.5

(6)

Eqs. (2), (5), (6) are three equations in three unknowns: S, E, and xB(E ) . For each solvent, solve Eq. (2) for xB(E ) . Solve (6) for E. Solve (5) for S. The results are:

Solvent Methyl acetate Isopropyl ether Heptadecanol Chloroform

KD 1.273 0.429 0.312 0.178

xB(E ) 0.01273 0.00429 0.00312 0.00178

E, kg/h

S, kg/h

74.984 222,500 305,940 536,260

74,030 221,500 305,000 535,300

Although methyl acetate is the best solvent, the solvent rates required are very large. To reduce the solvent rate, use a countercurrent, multiple-stage system.

Exercise 4.46 Subject:

Liquid-liquid extraction of ethylene glycol from water by furfural with one stage.

Given: Feed, F = 45 kg, of 30 wt% ethylene glycol (B) and 70 wt% water (A). Phase equilibrium diagrams of Fig. 4.14a and 4.14e for 25oC. Find: (a) Minimum amount of solvent. (b) Maximum amount of solvent. (c) % glycol extraction and amounts of solvent-free extract and raffinate for 45 kg solvent. (d) Maximum possible glycol purity in extract. Maximum purity of water in raffinate. Analysis: For a single stage, all mixtures of feed, F, and solvent, S, lie on a straight line between these two points as shown in the following ternary diagram of Fig. 4.14a. (a) The minimum amount of solvent corresponds to the maximum solubility of the solvent in the feed. This is point M1 in the diagram below. By the inverse lever arm rule, S/F = 0.097. Therefore, Smin = 0.0972(45) = 4.4 kg. In this case, no extract is obtained. (b) The maximum amount of solvent corresponds to maximum solubility of the feed in the solvent. This is point M2 in the diagram below. By the inverse lever arm rule, S/F = 11.15. Thus, Smax = 11.2(45) = 504 kg. In this case, no raffinate is obtained.

Exercise 4.46 (continued) Analysis: (continued) (c) With 45 kg of solvent, S/F = 1. Therefore, the mixing point, M3 is at the mid point between F and S in the diagram below. A tie line drawn through point M3 determines the raffinate, R, and the extract, E. By total material balance, R + E = F + S = 45 + 45 = 90. By the inverse lever arm rule, R/E = 0.61. Combining these equations gives: E = 55.9 kg, R = 34.1 kg. From the diagram, the composition of the extract is: 19 wt% B, 76 wt % C, and 5 wt% A. Therefore, the extract contains (0.19)(55.9) = 10.62 kg B. The composition of the raffinate is 8 wt% B, 84 wt% A, and 8 wt% C. The % extraction of glycol (B) = 10.62/[(0.30)(45)] x 100% = 78.7%. The amount of solvent-free extract = (55.9)(1 - 0.76) = 13.4 kg. The amount of solvent-free raffinate = (34.1)(1 - 0.08) = 31.4 kg.

Exercise 4.46 (continued) Analysis: (continued) (d) The maximum possible glycol purity in the extract occurs when the minimum amount of solvent is used, as discussed in part (a), giving raffinate R1. In this case, have say just one drop of extract, corresponding to point E1, which connects to R1 by a tie line in the diagram below. At point E1, have 48 wt% glycol. The maximum purity of water in the raffinate occurs when the maximum amount of solvent is used, as discussed in part (b), giving extract E2. In this case, have say just one drop of raffinate, corresponding to point R2, which connects to E2 by a tie line in the diagram below. At point R2, have 90 wt% water.

Exercise 4.47 Subject: Representation of the composition of a ternary mixture on a triangular diagram. Given: A triangular diagram where each vertex represents a pure component. Assumptions: Consider the case of an equilateral triangular diagram. Prove: The composition of any point inside the triangle is proportional to the length of the respective perpendicular drawn from the point to the side of the triangle opposite the vertex in question. Analysis: In the triangular diagram below, the pure components are E, R, and S. A mixture of these components is represented by the point M. For the equilateral triangle shown, the sum of the lengths of the three perpendiculars drawn from an interior point, such as M, to the three sides equals the altitude, is the same length from each side. Therefore, divide each altitude into 100 divisions and number these divisions starting with 0 at the base to 100 at the apex. Thus, if the divisions represent wt% (or mol%), the sum of the perpendiculars equals 100%. In the diagram below, each division is 10%. The perpendicular s measures 28% and is the composition of S. The perpendicular r measures 18% and is the composition of R. The perpendicular e measures 54% and is the composition of E. This proof is extended to a triangle of any shape on pages 11 to 18 of "Chemical Process Principles, Part I" by Hougen, Watson, and Ragatz.

Exercise 4.48 Subject:

Liquid-liquid extraction of acetic acid from chloroform by water at 18oC and 1 atm.

Given: Equilibrium data for the ternary mixture Assumptions: Equilibrium stages. Find: (a) Compositions and weights of raffinate and extract when 45 kg of a 35 wt% chloroform (C) and 65 wt% acetic acid (A) feed mixture (F) is extracted with 22.75 kg of water (S) in a single-stage extraction. (b) Compositions and weights of raffinate and extract if the raffinate from part (a) is extracted again with half its weight of water. (c) Composition of the raffinate from part (b) if all the water is removed from it. Use a right-triangle diagram of the equilibrium data, which is easily produced Analysis: with a spreadsheet. (a) In the diagram on the next page, the feed and solvent are represented by points F and S, respectively. The mixing point is M1, which is the sum of the feed and solvent (67.75 kg) with an overall composition of 33.58 wt% S, 23.25 wt% C, and 43.17 wt% A. A tie line ing through point M1 locates, on the equilibrium curve, the extract E1 and the raffinate R1. If the inverse lever arm rule is used to obtain E1 and R1, and their compositions are read from the diagram, the following results are obtained: Feed Solvent Extract Raffinate F S E1 R1 Amount, kg 45 22.75 55 12.75 Composition, wt%: Chloroform 35 0 11.5 74.5 Acetic acid 65 0 48.0 22.0 Water 0 100 40.5 3.5 (b) If R1 is mixed with half its weight of solvent (6.375 kg), the mixing point is M2, shown in the diagram on the next page, with an overall composition of 14.6 wt% A, 49.7 wt% C, and 35.7 wt% S. . A tie line ing through point M2 locates, on the equilibrium curve, the extract E2 and the raffinate R2. If the inverse lever arm rule is used to obtain E2 and R2, and their compositions are read from the diagram, the following results are obtained: Feed Solvent Extract Raffinate Water-free (R1) S E2 R2 Raffinate Amount, kg 12.75 6.375 8.895 10.23 10.10 Composition, wt%: Chloroform 74.5 0 1.0 91.0 93.2 Acetic acid 22.0 0 24.0 6.7 6.8 Water 3.5 100 74.9 1.3 0.0 (c) The water-free raffinate is included in the above table.

Exercise 4.48 (continued)

Exercise 4.49 Subject:

L-L extraction of acetic acid from water by isopropyl ether at 25oC and 1 atm.

Given: Equilibrium data for the ternary mixture Assumptions: Equilibrium stages. Find: (a) Compositions and weights of raffinate and extract when 100 kg of a 30 wt% acetic acid (A) and 70 wt% water (W) feed mixture (F) is extracted with 120 kg of isopropyl ether (E) in a single-stage extraction. Weight % of A in the extract if E is removed. (b) Compositions and weights of raffinate and extract if 52 kg of A and 48 kg of W are ed with 40 kg of E Analysis: Use a right-triangle diagram of the equilibrium data, which is easily produced with a spreadsheet. (a) In the diagram on the next page, the feed and solvent are represented by points F1 and S, respectively. The mixing point is M1, which is the sum of the feed and solvent (220 kg) with an overall composition of 13.6 wt% A, 31.8 wt% W, and 54.6 wt% E. A tie line ing through point M1 locates, on the equilibrium curve, the extract E1 and the raffinate R1. If the inverse lever arm rule is used to obtain E1 and R1, and their compositions are read from the diagram, the following results are obtained, including the amount and composition of the ether-free extract. Feed Solvent Extract Raffinate Ether-free F1 S E1 R1 Extract Amount, kg 100 120 133.4 86.6 16.1 Composition, wt%: Water 70 0 2.9 76.3 24.2 Acetic acid 30 0 9.1 20.6 75.8 Isopropyl ether 0 100 88.0 3.1 0.0 (b) In the diagram on the next page, the feed and solvent are represented by points F2 and S, respectively. The mixing point is M2, which is the sum of the feed and solvent (140 kg) with an overall composition of 37.1 wt% A, 34.3 wt% W, and 28.6 wt% E. A tie line ing through point M2 locates, on the equilibrium curve, the extract E2 and the raffinate R2. If the inverse lever arm rule is used to obtain E2 and R, and their compositions are read from the diagram, the following results are obtained: Feed Solvent Extract Raffinate F2 S E2 R2 Amount, kg 100 40 55.0 85.0 Composition, wt%: Water 48 0 9.3 50.5 Acetic acid 52 0 28.9 42.5 Isopropyl ether 0 100 61.8 7.0

Exercise 4.49 (continued)

Exercise 4.1 Subject: Degrees of freedom analysis for a three-phase equilibrium stage. Given: Equilibrium stage of Figure 4.35, with two feeds (one vapor, one liquid), vapor entering from stage below, liquid entering from stage above, three exiting streams (one vapor, two liquid), and heat transfer. Assumptions: Equilibrium stage Find: (a) (b) (c) (d) Analysis:

List and count of variables. List and count of equations. Number of degrees of freedom. List of reasonable set of design variables. (a) With 4 streams in and 3 streams out, and heat transfer, Number of variables = NV = 7(C+3) + 1 = 7C + 22

The variables are 7 total flow rates, 7 temperatures, 7 pressures, 1 heat transfer rate and C mole fractions for each of the 7 streams. (b) The equations are: C Component material balances 1 Energy balance 2 Pressure identity equations for the 3 exiting streams 2 Temperature identity equations for the 3 exiting streams 7 Mole fraction sums (one for each stream) y y 2C Phase equilibrium equations: KiI = iI and KiII = IIi xi xi Total number of equations = NE = 3C + 12 (c) Degrees of freedom = ND= NV - NE = (7C + 22) - (3C + 12) = 4C +10 (d) A possible set of specifications is: For each entering stream: Total flow rate, temperature, pressure, and C-1 mole fractions, which totals 4(C + 2) = 4C + 8 For the remaining 2 variables, choose any combination of Q, temperature of one of the three exiting streams, and/or pressure of one of the three exiting streams.

Exercise 4.2 Subject: Determination of uniqueness of three different operations. Given: (a) An adiabatic equilibrium stage with known vapor and liquid feed streams, and known stage temperature and pressure. (b) Same as (a), except that stage is not adiabatic. (c) Partial condenser using cooling water, with known vapor feed (except for flow rate), outlet pressure, and inlet cooling water flow rate. Assumptions: Exiting streams in equilibrium. Find:

(a) Whether composition and amounts of exiting vapor and liquid can be computed. (b) Same as part (a). (c) Whether cooling water rate can be computed.

Analysis: (a) With two steams in and two out, number of variables = NV = 4(C + 3) = 4C + 12 Equations are: C Component material balances 1 Energy balance 1 Pressure identity for 2 exiting streams 1 Temperature identity for 2 exiting streams 4 Mole fraction sums for 4 streams C Phase equilibrium equations Therefore, number of equations = NE =2C + 7 Degrees of freedom = ND= NV - NE = (4C + 12) - (2C + 7) = 2C +5 Given specifications are: 2C + 4 variables for the two feed streams. Only one specification left. Therefore can not specify both T and P for exiting streams. (b) If stage in part (a) is not adiabatic, add Q as a variable to give NV = 4C + 13. The number of equations stays the same, i. e. NE =2C + 7. Thus, have one additional degree of freedom, giving, ND= NV - NE = 2C +6. Can now specify both T and P for exiting streams. (c) First, consider just the partial condensation of the vapor into two exiting streams by heat transfer, Q, without considering the cooling water. For three streams, NV =3(C + 3) + 1 (for Q) = 3C +10. Equations are: C Component material balances 1 Energy balance 1 Pressure identity for 2 exiting streams 1 Temperature identity for 2 exiting streams 3 Mole fraction sums for 3 streams C Phase equilibrium equations Therefore, NE = 2C + 6 and ND = NV - NE = C + 4

Exercise 4.2 (continued) Analysis: (c) (continued) Specified for the feed vapor are only C + 1 variables, because the feed rate is not specified. Also the outlet pressure of the condenser is specified. This give C + 2. We are short two variables from being able to compute Q. An energy balance on the cooling water gives: Q = m Tout − Tin

But only Tin is given. Thus, with Q unknown and Tout not given, we are three variable short of being able to compute the water rate, m. Thus, the problem can not be solved uniquely. We could solve it if the vapor feed rate, the outlet temperature of the partial condensate, and the cooling water outlet temperature were specified.

Exercise 4.3 Subject: Degrees of freedom analysis for an adiabatic, two-phase flash. Given: Continuous, adiabatic flash of one feed into vapor and liquid products Assumptions: Exiting streams are in equilibrium Find: (a) (b) (c) (d) (e) Analysis:

Number of variables. All equations relating variables. Number of equations. Number of degrees of freedom Preferred specifications (a) Variables are those appearing in Figure 4.36 N V = 3C + 9 (b) C Component material balances 1 Energy balance 1 Pressure identity for two exiting streams 1 Temperature identity for two exiting streams 3 Mole fraction sums for three streams C Vapor-liquid equilibrium equations (c) NE = 2C + 6 (d) ND = NV - NE = (3C + 9) - (2C + 6) = C + 3 (e) Specify the feed completely ( feed rate, temperature, pressure and C - 1 mole fractions) plus exiting pressure.

Exercise 4.4 Subject: Degrees of freedom analysis for a non-adiabatic three-phase flash. Given: Continuous, non-adiabatic flash of a liquid feed to produce a vapor and two liquid phases as shown in Figure 4.33. Assumptions: The three exiting phases are in equilibrium. Find: Number of degrees of freedom. Analysis: The variables are the heat transfer rate and four each of stream flow rates, temperatures, pressures, and C mole fractions. Thus, NV = 4C + 13. The equations are: C Component material balances 1 Energy balance 2 Pressure identities for three exiting streams 2 Temperature identities for three exiting streams 4 Mole fraction sums for four streams 2C Phase equilibrium relations: KiI = yi / xiI and KiII = yi / xiII Therefore, NE = 3C + 9 Number of degrees of freedom = ND = NV - ND = (4C + 13) - (3C + 9) = C + 4

Exercise 4.5 Subject: Application of Gibbs phase rule to seven-phase system of Figure 4.31. Given: One gas and six liquid phases in equilibrium. Assumptions: Gas phase includes N2 , O2 , and argon. Find: Number of degrees of freedom by Gibbs phase rule. Possible set of specifications to fix system. Analysis: From Eq. (4-1), Number of degrees of freedom = C - number phases + 2 Number of components = 9 (N2 , O2 , argon, n-hexane, aniline, water, phosphorus, gallium, and mercury. Number of phases = 7 Number of degrees of freedom = 9 - 7 + 2 = 4 Specify T, P, and mole fractions of argon and oxygen in the air.