Sunmica 6i6932

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3i3n4

Overview 26281t

& View Sunmica as PDF for free.

More details 6y5l6z

- Words: 1,649

- Pages: 4

INTRODUCTION • Sunmica is another name for decorative laminates and it is primarily used as a surface finish pasted on top of another wooden or board . • Decorative laminates are artificially created materials that are made from paper and plastic resins. • Decorative Laminates that resemble wood veneers are also quite popular.

MACHINES USED: • The main machinery and equipments required for making laminates/sunmica are listed below. • PIL (Paper Impregnation Line) • Drying and Cooling Machines • Cutting Machines (for cutting the papers/laminate sheets to standard or desired sizes as per market requirements) • Hydraulic Press • Steel Plates (used to separate different laminate sheets while pressing, and to etch desired patterns and textures on the sunmica/laminate) • Sanding Machines (for sanding the bottom/brown side of the finished laminate sheet)

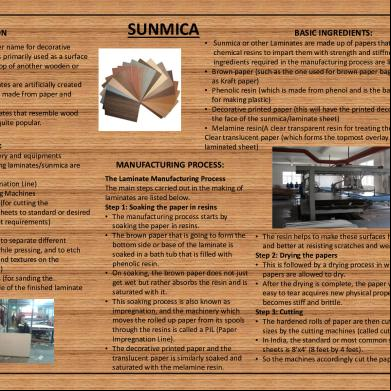

SUNMICA

BASIC INGREDIENTS: • Sunmica or other Laminates are made up of papers that are treated with chemical resins to impart them with strength and stiffness. The main ingredients required in the manufacturing process are listed below. • Brown paper (such as the one used for brown paper bags. It is also known as Kraft paper) • Phenolic resin (which is made from phenol and is the basic material used for making plastic) • Decorative printed paper (this will have the printed decorative design for the face of the sunmica/laminate sheet) • Melamine resin(A clear transparent resin for treating the decorative paper) Clear translucent paper (which forms the topmost overlay of the decorative laminated sheet)

MANUFACTURING PROCESS: The Laminate Manufacturing Process The main steps carried out in the making of laminates are listed below. Step 1: Soaking the paper in resins • The manufacturing process starts by soaking the paper in resins. • The brown paper that is going to form the bottom side or base of the laminate is soaked in a bath tub that is filled with phenolic resin. • On soaking, the brown paper does not just get wet but rather absorbs the resin and is saturated with it. • This soaking process is also known as impregnation, and the machinery which moves the rolled up paper from its spools through the resins is called a PIL (Paper Impregnation Line). • The decorative printed paper and the translucent paper is similarly soaked and saturated with the melamine resin.

• The resin helps to make these surfaces harder, stiffer and better at resisting scratches and wear and tear. Step 2: Drying the papers • This is followed by a drying process in which the soaked papers are allowed to dry. • After the drying is complete, the paper which earlier was easy to tear acquires new physical properties. It becomes stiff and brittle. Step 3: Cutting • The hardened rolls of paper are then cut to the desired sizes by the cutting machines (called cutters). • In India, the standard or most common size for laminate sheets is 8'x4' (8 feet by 4 feet). • So the machines accordingly cut the papers to this size.

Step 4: High-pressure pressing and bonding

•

• • •

• The next step in the laminate manufacturing process is to hard press these papers together under high pressure and temperature. • This is done using hydraulic presses. • The papers or sheets are stacked upon each other. • The brown paper forms the bottom sheet followed by the decorative sheet, and the topmost layer is of the clear translucent paper. • The huge hydraulic presses are designed to press large number of laminate sheets at a single go. So all the laminates that are to be pressed are placed one upon another with steel separator plates interspersed between them (so that the separate laminate sheets do not stick with each other while being pressed). The steel sheets also serve another purpose. They are designed to carry textures or patterns on them that get etched on to the surface of the sunmica/laminate sheet while being pressed. The pressing is one of the most important processes in the manufacturing of laminate sheets and is the reason why decorative laminates are often referred to as HPL and HPDL (High-pressure decorative laminates).

• Step 5: Sanding the non-decorative side • In the final step of the process, the bottom side (non-decorative side) is uniformly sanded by a sanding machine. • The sanding process makes this surface better suited for adhesion to surfaces. • This sanded surface is the one on which carpenters apply Fevicol (or other adhesives) while glueing these sunmica/laminate sheets over plywood or other base substrate materials.

• Step 6: Testing, Packing, Shipping • Samples of the finished products may be subjected to standard quality tests for laminates as per norms, and these sheets are then packaged and shipped to the regular distribution channels of the laminate companies.

THICKNESS: • The thickness of Laminate sheets usually ranged from 0.6 mm to 1.5 mm, and accordingly more layers of paper can be used in the process. • Much thicker laminate sheets (3mm to 30mm thickness) are also manufactured and these are known as compact laminated sheets. • These compact types are stiff and self-ing. Such compact sheets can be used independently without the need to glue them onto plywood, particle board, MDF or any other base materials. • Thin single face Sun mica finishes/ decorative laminates have thickness of less than 2mm. • High pressure sun mica finishes/ decorative laminates are available in thickness of 0.8, 1.0 and 1.5 mm.

TYPES: Muscovite mica- KAl2(AlSi3O10)(OH)2 - has greater dielectric strength than any other insulating material. • It sures all mica in dielectric strength, thermal endurance, mechanical strength, moisture resistance, transparency, flexibility, resilience, toughness and perfection of cleavage and is therefore recognized as the best Mica for electrical and electronics devices. • It is almost insensitive to atmospheric weathering and offers greater resistance to outside chemical influence • . Muscovite Mica is harder than Phlogopite Mica. • Muscovite Mica is the most commonly used Mica in electrical insulation and since it has the best electrical properties of all Mica. • High quality Mica cleaves the easiest and into the thinnest sheets and with the fewest imperfections that could be seen at the atomic or near atomic scale with AFM or TEM instrumentation.

• Muscovite Mica is commonly divided into two color groups: Ruby : varies in color from clear to pink to red / brown Green: varies in color from pale green to olive to dark green

• • • •

•

• • • •

Ruby Muscovite : Color ranges from an almost white through pink to a light ruby and into shades of brownish ruby and brown. Ruby Mica has excellent cleavage capabilities permitting it to be split into the thinnest desired film without the risk of cracking. Green Muscovite : Ranges from light to pale green through yellowish and olive green to a dark green. Color as such has less significant influence on quality. Still ruby Muscovite is generally preferred especially in the higher qualities as it is considered to be superior to green Mica for applications requiring high dielectric strength and low power loss (or high Q). Ruby and green Mica have excellent cleavage permitting it to be split into the thinnest desired film without the risk of cracking. Use of ruby and green Mica is a matter of preference and application. 2. Phologopite Mica - KMg3(AlSi3O10)(OH)2 - is a hydrous potassium magnesium aluminium silicate. Here the calcination temperature is reached at about 800 C. Generally speaking, Phlogopite Mica is softer than Muscovite mica and this for instance makes it more suitable for the manufacture of commutator micanite used in commutators of flush running designs.

• Phlogopite Mica is commonly called amber mica and varies in color from light silver to dark brown. • Phlogopite Mica has poor electrical properties and chemical resistance in comparision to Muscovite mica.

Installation/ fixing: • The Sun mica / laminates are fixed on the ing base of ply wood, block board, particle board etc by adhesives. • The ing base should be sanded and free from dust, wax, grease etc. • After applying proper adhesive the sheet of laminate is spread and hand rolled from centre to edge and remove all air bubbles. • To ensure adequate bond, sufficient pressure should be applied over the entire area of assembly.

Finishing: Decorative laminates come pre-finished and do not require any additional finishing.

Durability: The laminates are durable and are used as surface materials and improve their resistance to wear, scratching and domestic stain etc.

Maintenance • Sunmica based furniture requires less maintenance compared to veneer based furniture. • General day to day maintenance can be done by just using dry or wet cloth to wipe the sunmica surface • These laminates do not take polish so there is no need to do periodic polish on these.

Color; Design • Sun mica / Laminate sheets come in a wide variety of colors, styles and designs. • These also come in artificial wooden grain styles or colors too so the laminate based designs have options for both natural designs and man-made designs • Laminates comes in matt and glossy finish.

• Advantages • • • • • • •

Lower cost Impact and scratch resistant Stain resistant Don't need wax or polish Easy to install Durable when compared to veneer It needs very little maintenance when compared to veneer.

• Disadvantages • Some design conscious people say that the Laminate based furniture is not rich looking furniture. • As laminates cover the base wood, it is hard to adjudge the quality of wood used under the laminate/sunmica

• IS Designation • Sun mica finishes/ decorative laminates should be according IS 2046-1995

• Uses • Sun mica finishes/ decorative laminates are used as surface materials on counters, desk tops, cabinets, wardrobes etc. • It is also used to provide a neat aesthetic surface on wall ing too.

MACHINES USED: • The main machinery and equipments required for making laminates/sunmica are listed below. • PIL (Paper Impregnation Line) • Drying and Cooling Machines • Cutting Machines (for cutting the papers/laminate sheets to standard or desired sizes as per market requirements) • Hydraulic Press • Steel Plates (used to separate different laminate sheets while pressing, and to etch desired patterns and textures on the sunmica/laminate) • Sanding Machines (for sanding the bottom/brown side of the finished laminate sheet)

SUNMICA

BASIC INGREDIENTS: • Sunmica or other Laminates are made up of papers that are treated with chemical resins to impart them with strength and stiffness. The main ingredients required in the manufacturing process are listed below. • Brown paper (such as the one used for brown paper bags. It is also known as Kraft paper) • Phenolic resin (which is made from phenol and is the basic material used for making plastic) • Decorative printed paper (this will have the printed decorative design for the face of the sunmica/laminate sheet) • Melamine resin(A clear transparent resin for treating the decorative paper) Clear translucent paper (which forms the topmost overlay of the decorative laminated sheet)

MANUFACTURING PROCESS: The Laminate Manufacturing Process The main steps carried out in the making of laminates are listed below. Step 1: Soaking the paper in resins • The manufacturing process starts by soaking the paper in resins. • The brown paper that is going to form the bottom side or base of the laminate is soaked in a bath tub that is filled with phenolic resin. • On soaking, the brown paper does not just get wet but rather absorbs the resin and is saturated with it. • This soaking process is also known as impregnation, and the machinery which moves the rolled up paper from its spools through the resins is called a PIL (Paper Impregnation Line). • The decorative printed paper and the translucent paper is similarly soaked and saturated with the melamine resin.

• The resin helps to make these surfaces harder, stiffer and better at resisting scratches and wear and tear. Step 2: Drying the papers • This is followed by a drying process in which the soaked papers are allowed to dry. • After the drying is complete, the paper which earlier was easy to tear acquires new physical properties. It becomes stiff and brittle. Step 3: Cutting • The hardened rolls of paper are then cut to the desired sizes by the cutting machines (called cutters). • In India, the standard or most common size for laminate sheets is 8'x4' (8 feet by 4 feet). • So the machines accordingly cut the papers to this size.

Step 4: High-pressure pressing and bonding

•

• • •

• The next step in the laminate manufacturing process is to hard press these papers together under high pressure and temperature. • This is done using hydraulic presses. • The papers or sheets are stacked upon each other. • The brown paper forms the bottom sheet followed by the decorative sheet, and the topmost layer is of the clear translucent paper. • The huge hydraulic presses are designed to press large number of laminate sheets at a single go. So all the laminates that are to be pressed are placed one upon another with steel separator plates interspersed between them (so that the separate laminate sheets do not stick with each other while being pressed). The steel sheets also serve another purpose. They are designed to carry textures or patterns on them that get etched on to the surface of the sunmica/laminate sheet while being pressed. The pressing is one of the most important processes in the manufacturing of laminate sheets and is the reason why decorative laminates are often referred to as HPL and HPDL (High-pressure decorative laminates).

• Step 5: Sanding the non-decorative side • In the final step of the process, the bottom side (non-decorative side) is uniformly sanded by a sanding machine. • The sanding process makes this surface better suited for adhesion to surfaces. • This sanded surface is the one on which carpenters apply Fevicol (or other adhesives) while glueing these sunmica/laminate sheets over plywood or other base substrate materials.

• Step 6: Testing, Packing, Shipping • Samples of the finished products may be subjected to standard quality tests for laminates as per norms, and these sheets are then packaged and shipped to the regular distribution channels of the laminate companies.

THICKNESS: • The thickness of Laminate sheets usually ranged from 0.6 mm to 1.5 mm, and accordingly more layers of paper can be used in the process. • Much thicker laminate sheets (3mm to 30mm thickness) are also manufactured and these are known as compact laminated sheets. • These compact types are stiff and self-ing. Such compact sheets can be used independently without the need to glue them onto plywood, particle board, MDF or any other base materials. • Thin single face Sun mica finishes/ decorative laminates have thickness of less than 2mm. • High pressure sun mica finishes/ decorative laminates are available in thickness of 0.8, 1.0 and 1.5 mm.

TYPES: Muscovite mica- KAl2(AlSi3O10)(OH)2 - has greater dielectric strength than any other insulating material. • It sures all mica in dielectric strength, thermal endurance, mechanical strength, moisture resistance, transparency, flexibility, resilience, toughness and perfection of cleavage and is therefore recognized as the best Mica for electrical and electronics devices. • It is almost insensitive to atmospheric weathering and offers greater resistance to outside chemical influence • . Muscovite Mica is harder than Phlogopite Mica. • Muscovite Mica is the most commonly used Mica in electrical insulation and since it has the best electrical properties of all Mica. • High quality Mica cleaves the easiest and into the thinnest sheets and with the fewest imperfections that could be seen at the atomic or near atomic scale with AFM or TEM instrumentation.

• Muscovite Mica is commonly divided into two color groups: Ruby : varies in color from clear to pink to red / brown Green: varies in color from pale green to olive to dark green

• • • •

•

• • • •

Ruby Muscovite : Color ranges from an almost white through pink to a light ruby and into shades of brownish ruby and brown. Ruby Mica has excellent cleavage capabilities permitting it to be split into the thinnest desired film without the risk of cracking. Green Muscovite : Ranges from light to pale green through yellowish and olive green to a dark green. Color as such has less significant influence on quality. Still ruby Muscovite is generally preferred especially in the higher qualities as it is considered to be superior to green Mica for applications requiring high dielectric strength and low power loss (or high Q). Ruby and green Mica have excellent cleavage permitting it to be split into the thinnest desired film without the risk of cracking. Use of ruby and green Mica is a matter of preference and application. 2. Phologopite Mica - KMg3(AlSi3O10)(OH)2 - is a hydrous potassium magnesium aluminium silicate. Here the calcination temperature is reached at about 800 C. Generally speaking, Phlogopite Mica is softer than Muscovite mica and this for instance makes it more suitable for the manufacture of commutator micanite used in commutators of flush running designs.

• Phlogopite Mica is commonly called amber mica and varies in color from light silver to dark brown. • Phlogopite Mica has poor electrical properties and chemical resistance in comparision to Muscovite mica.

Installation/ fixing: • The Sun mica / laminates are fixed on the ing base of ply wood, block board, particle board etc by adhesives. • The ing base should be sanded and free from dust, wax, grease etc. • After applying proper adhesive the sheet of laminate is spread and hand rolled from centre to edge and remove all air bubbles. • To ensure adequate bond, sufficient pressure should be applied over the entire area of assembly.

Finishing: Decorative laminates come pre-finished and do not require any additional finishing.

Durability: The laminates are durable and are used as surface materials and improve their resistance to wear, scratching and domestic stain etc.

Maintenance • Sunmica based furniture requires less maintenance compared to veneer based furniture. • General day to day maintenance can be done by just using dry or wet cloth to wipe the sunmica surface • These laminates do not take polish so there is no need to do periodic polish on these.

Color; Design • Sun mica / Laminate sheets come in a wide variety of colors, styles and designs. • These also come in artificial wooden grain styles or colors too so the laminate based designs have options for both natural designs and man-made designs • Laminates comes in matt and glossy finish.

• Advantages • • • • • • •

Lower cost Impact and scratch resistant Stain resistant Don't need wax or polish Easy to install Durable when compared to veneer It needs very little maintenance when compared to veneer.

• Disadvantages • Some design conscious people say that the Laminate based furniture is not rich looking furniture. • As laminates cover the base wood, it is hard to adjudge the quality of wood used under the laminate/sunmica

• IS Designation • Sun mica finishes/ decorative laminates should be according IS 2046-1995

• Uses • Sun mica finishes/ decorative laminates are used as surface materials on counters, desk tops, cabinets, wardrobes etc. • It is also used to provide a neat aesthetic surface on wall ing too.