Totem Catalogue 1 74p5j

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3i3n4

Overview 26281t

& View Totem Catalogue 1 as PDF for free.

More details 6y5l6z

- Words: 6,911

- Pages: 28

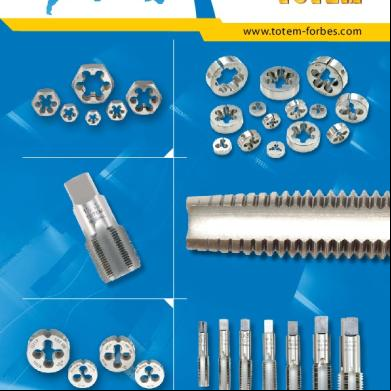

www.totem-forbes.com

World class threading tools from

2009

Forbes Precision Tools manufactures High Speed Steel Threading Taps and Dies, Carbon Steel Threading Taps and Dies, Tungsten Carbide Rotary Burrs, Solid Carbide Tools and Spring Washer. Forbes Precision Tools is a part of FORBES & COMPANY LTD., which was started in 1767. This division began its manufacturing during 1963 in collaboration with Nuckey Scott & Company Ltd. UK, the manufacturers of world famous “WARRIOR” brand of threading tools. The manufacturing of Tungsten Carbide Burrs began in 1968 with the technical knowhow from B.O. Morris, U.K. Solid Carbide tools manufacturing began in 1997 under t operation with M.A. Ford, USA. We hold leadership position in India. Our tools are manufactured and sold under “TOTEM” brand name. ‘TOTEM’ is committed to being the leading manufacturer with quality and reliability for its customers. The tools are manufactured on latest CNC machines with strict quality procedures and skilled technical team. Continuous investments are made in research and development to keep pace with the latest technology. At FORBES, the endeavour continue….

Quality Policy We commit ourselves to the enhancement of customer satisfaction and maintaining global market presence by development, manufacturing and marketing of excellent products. This involves continual improvement of processes, participation of employees and suppliers.

Strategic quality objectives 1. To enhance customer satisfaction by –

A. Consistent quality.

B. On time delivery.

C. Prompt after sales service.

D. Focus on evolving needs of customer.

2. Education, training and development of employees to enable them to utilise their full potential in meeting company objectives which are as follows :

A. To enhance cost effectiveness of company by identifying and

eliminating non value added activities.

B. Technology up gradation by reconditioning, retrofitting and innovation.

G. Mukharji (Director - Engineering)

A Product of Total Engineering Excellence

Q

uality: All tools are manufactured from first-grade high Carbon Steel and High Speed Steel and are designed to meet the most stringent engineering demands.

H

eat Treatment: All tools are heat treated in atmospheric controlled furnaces with modern timers and temperature controllers which are strictly calibrated periodically to ensure correct heat treatment of tools with no decarb.

I

nspection: Every tool we supply es through stringent inspection tests. Our factory is equipped with the most modern and precise equipments, which are periodically calibrated.

F

inish: A high level of finish is maintained in keeping with the requirements of a precision cutting tool.

P

resentation: All tools are packed in attractive boxes distinctly labeled with Holograms.

S T

olerances: Thread to Zone 5 of BS 949: 1951.

tandards: Carbon Steel taps are manufactured as per British Standard BS 949: 1951 and American standard ANSI 94.9: 1971. Dies and Die Nuts are manufactured as per British Standard BS 1127: 1974

T

hread direction: All tools are supplied for Right Hand screwing. Tools for Left Hand screwing can also be supplied against requirement.

INDEX PRODUCT SPECIFICATIONS

PAGE NO.

CARBON STEEL TAPS Metric Coarse

06

Metric Fine

07

BSW/BSF

08

UNC/UNF

09

BSPT/NPT

10

BA/BSB

11

BS CYCLE/ME/BS CONDUIT

12

UNS/WHITWORTH FINE

13

BSPF/NPS

14

CIRCULAR SPLIT DIES CARBON STEEL AND HIGH SPEED STEEL

16-17

HIGH SPEED STEEL GROUND DIES

18

HEXAGONAL DIES / DIE NUTS

19

CARBON STEEL AND HIGH SPEED STEEL TAP AND DIE CASE SETS

20-21

Tap Wrench and Die Stocks

22

Tap and Die terminology

23

Application of products

24

“TOTEM” range of products

25

and Conditions

26

METRIC COARSE BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

6

Nominal Diameter D

Pitch mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

2.0 2.2 2.5 3.0 3.5 4.0 4.5 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 12.0 14.0 14.0 16.0 18.0 20.0 22.0 24.0 27.0 30.0 33.0 36.0 39.0 42.0 45.0 48.0 52.0

0.40 0.45 0.45 0.50 0.60 0.70 0.75 0.80 1.00 1.00 1.25 1.25 1.50 1.50 1.50 1.75 1.50 2.00 2.00 2.50 2.50 2.50 3.00 3.00 3.50 3.50 4.00 4.00 4.50 4.50 5.00 5.00

42.9 44.5 46.0 47.6 50.8 54.0 60.3 60.3 63.5 63.5 69.9 74.6 74.6 80.2 85.7 85.7 91.3 91.3 96.8 102.4 108.0 119.1 124.6 130.2 138.1 146.1 154.0 161.9 169.9 177.8 185.7 193.7

9.5 11.1 12.7 14.3 17.5 19.1 22.2 22.2 25.4 25.4 28.6 31.8 31.8 36.5 42.1 42.1 42.1 42.1 46.0 46.0 50.8 56.4 56.4 63.5 65.1 65.1 76.2 76.2 81.0 81.0 90.5 90.5

4.8 4.8 4.8 4.8 4.8 6.4 6.4 6.4 7.1 7.9 8.7 10.3 10.3 10.3 11.1 11.1 12.7 12.7 14.3 15.9 17.5 19.1 19.1 20.6 22.2 25.4 27.0 28.6 28.6 31.8 31.8 31.8

2.7 2.7 2.7 2.7 2.9 3.4 3.8 4.2 4.8 5.6 6.3 7.0 7.8 6.1 7.0 7.0 8.2 8.2 9.1 10.3 11.2 13.3 14.5 15.2 17.1 19.5 21.1 23.5 24.9 27.2 28.9 28.9

3.3 3.3 3.3 3.3 3.7 4.2 4.8 5.4 6.1 7.2 8.2 9.1 10.3 8.2 9.3 9.3 10.9 10.9 12.2 13.8 15.0 17.7 19.3 20.3 22.8 25.9 28.1 31.3 33.1 36.3 38.6 38.6

1.60 1.75 2.05 2.50 2.90 3.30 3.70 4.20 5.00 6.00 6.80 7.80 8.50 9.50 10.50 10.20 12.50 12.00 14.00 15.50 17.50 19.50 21.00 24.00 26.50 29.50 32.00 35.00 37.50 40.50 43.00 47.00

METRIC FINE BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

Pitch mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

2.30 2.60 3.00 4.00 4.00 5.00 5.00 5.50 6.00 8.00 8.00 9.00 10.00 10.00 10.00 12.00 12.00 14.00 16.00 18.00 20.00 22.00 24.00 25.00 26.00 27.00 28.00 30.00 30.00 32.00 40.00

0.40 0.45 0.60 0.50 0.75 0.50 0.90 0.90 0.75 0.75 1.00 1.00 0.75 1.00 1.25 1.00 1.25 1.25 1.00 1.50 1.00 1.50 1.50 1.50 1.50 1.50 1.50 1.50 2.00 1.50 1.50

44.5 47.6 47.6 54.0 54.0 60.3 60.3 60.3 63.5 69.9 69.9 74.6 74.6 74.6 74.6 76.2 76.2 76.2 76.2 76.2 82.6 82.6 82.6 82.6 82.6 82.6 101.6 101.6 101.6 101.6 101.6

11.1 14.3 14.3 19.1 19.1 22.2 22.2 22.2 25.4 28.6 28.6 31.8 31.8 31.8 31.8 31.8 31.8 31.8 31.8 31.8 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1

4.8 4.8 4.8 6.4 6.4 6.4 6.4 6.4 7.1 8.7 8.7 10.3 10.3 10.3 10.3 11.1 11.1 12.7 14.3 15.9 17.5 19.1 19.1 20.6 20.6 20.6 20.6 22.2 22.2 25.4 28.6

2.7 2.7 2.7 3.4 3.4 4.2 4.2 4.4 4.8 6.3 6.3 7.0 7.8 7.8 7.8 7.0 7.0 8.2 9.1 10.3 11.2 13.3 14.5 15.2 15.2 15.2 15.9 17.1 17.1 19.5 23.5

3.3 3.3 3.3 4.2 4.2 5.4 5.4 5.6 6.1 8.2 8.2 9.1 10.3 10.3 10.3 9.3 9.3 10.9 12.2 13.8 15.0 17.7 19.3 20.3 20.3 20.3 21.2 22.8 22.8 25.9 31.3

1.90 2.10 2.40 3.50 3.25 4.50 4.10 4.60 5.20 7.20 7.00 8.00 9.20 9.00 8.80 11.00 10.75 12.75 15.00 16.50 19.00 20.50 22.50 23.50 24.50 25.50 26.50 28.50 28.00 31.50 38.00

7

BSW / BSF

BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

8

Nominal Diameter D

T.P.I. (BSW)

1/16” 3/32” 1/8” 5/32” 3/16” 7/32” 1/4” 9/32” 5/16” 3/8” 7/16” 1/2” 9/16” 5/8” 11/16” 3/4” 13/16” 7/8” 15/16” 1" 1-1/8" 1-1/4" 1-3/8" 1-1/2" 1-3/4" 2"

60 48 40 32 24 24 20 20 18 16 14 12 12 11 11 10 10 9 9 8 7 7 6 6 5 4.1/2

T.P.I. (BSF)

L mm

I mm

I1 mm

a mm

d mm

32 28 26 26 22 20 18 16 16 14 14 12 12 11 11 10 9 9 8 8 7 7

41.3 46.0 49.2 54.0 60.3 60.3 63.5 63.5 69.9 74.6 80.2 85.7 91.3 96.8 102.4 108.0 113.5 119.1 124.6 130.2 138.1 146.1 154.0 161.9 177.8 193.7

7.9 12.7 15.9 19.1 22.2 22.2 25.4 25.4 28.6 31.8 36.5 42.1 42.1 46.0 46.0 50.8 50.8 56.4 56.4 63.5 65.1 65.1 76.2 76.2 81.0 90.5

4.8 4.8 4.8 6.4 6.4 6.4 7.1 7.9 8.7 10.3 10.3 11.1 12.7 14.3 15.9 17.5 17.5 19.1 19.1 20.6 22.2 25.4 27.0 28.6 31.8 34.9

2.7 2.7 2.7 3.1 3.8 4.4 5.0 5.6 6.1 7.5 6.1 7.0 8.2 9.1 10.3 11.2 12.4 13.3 14.5 15.2 17.1 19.5 21.1 23.5 27.2 31.3

3.3 3.3 3.3 4.0 4.8 5.6 6.4 7.2 8.0 9.6 8.2 9.3 10.9 12.2 13.8 15.0 16.6 17.7 19.3 20.3 22.8 25.9 28.1 31.3 36.3 41.8

Tapping drill sizes (BSW) mm 1.20 1.90 2.55 3.20 3.70 4.50 5.10 5.80 6.50 7.90 9.30 10.50 12.10 13.50 15.00 16.25 18.00 19.25 21.00 22.00 24.75 28.00 31.00 33.50 39.00 44.50

Tapping drill sizes (BSF) mm

4.00 4.60 5.30 6.10 6.80 8.30 9.70 11.10 12.70 14.00 15.50 16.75 18.50 19.75 21.00 22.75 25.50 28.50 31.50 34.50 40.50 46.80

(U) NC / (U) NF ANSI 94.9 : 1971

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

T.P.I. (U)NC

T.P.I. (U)NF

L mm

I mm

I1 mm

a mm

d mm

0 1 2 3 4 5 6 8 10 12 1/4” 5/16” 3/8” 7/16” 1/2” 9/16” 5/8” 3/4” 7/8” 1" 1-1/8" 1-1/4" 1-3/8" 1-1/2" 1-3/4" 2"

– 56 56 48 40 40 32 32 24 24 20 18 16 14 13 12 11 10 9 8 7 7 6 6 5 4.1/2

80 72 64 56 48 44 40 36 32 28 28 24 24 20 20 18 18 16 14 12 12 12 12 12 – –

41.3 42.9 44.5 46.0 47.6 49.2 50.8 54.0 60.3 60.3 63.5 69.1 74.6 80.2 85.7 91.3 96.8 108.0 119.1 130.2 138.1 146.1 154.0 161.9 177.8 193.7

7.9 9.5 11.1 12.7 14.3 15.9 17.5 19.1 22.2 23.8 25.4 28.6 31.8 36.5 42.1 42.1 46.0 50.8 56.4 63.5 65.1 65.1 76.2 76.2 81.0 90.5

4.8 4.8 4.8 4.8 4.8 4.8 4.8 6.4 6.4 7.1 7.9 9.5 11.1 10.3 11.1 12.7 14.3 17.5 19.1 20.6 22.2 25.4 27.0 28.6 31.8 34.9

2.8 2.8 2.8 2.8 2.8 2.8 2.8 3.3 3.9 4.2 4.9 6.0 7.3 6.1 7.0 8.2 9.1 11.2 13.3 15.2 17.1 19.5 21.1 23.5 27.2 31.3

3.6 3.6 3.6 3.6 3.6 3.6 3.6 4.3 4.9 5.6 6.5 8.1 9.7 8.2 9.3 10.9 12.2 15.0 17.7 20.3 22.8 25.9 28.1 31.3 36.3 41.8

Tapping Tapping Drill Sizes Drill sizes ((U)NC) mm ((U)NF) mm – 1.55 1.85 2.10 2.35 2.65 2.85 3.50 3.90 4.50 5.10 6.60 8.00 9.40 10.80 12.20 13.50 16.50 19.50 22.25 25.00 28.00 30.75 34.00 39.50 45.00

1.25 1.55 1.90 2.15 2.40 2.70 2.95 3.50 4.10 4.70 5.50 6.90 8.50 9.90 11.50 12.90 14.50 17.50 20.40 23.25 26.50 29.50 32.75 36.00 – –

9

BSPT

BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

T. P. I.

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm) without reamer

1/8” 1/4” 3/8” 1/2” 5/8” 3/4” 7/8” 1” 1.1/4” 1.1/2” 2"

28 19 19 14 14 14 14 11 11 11 11

54.0 61.9 65.1 79.4 81.0 82.6 88.9 95.3 101.6 108.0 114.3

19.1 27.0 27.0 34.9 34.9 34.9 39.7 44.5 44.5 44.5 44.5

7.9 11.1 12.7 15.9 17.5 17.5 19.1 20.6 23.8 25.4 28.6

6.05 8.18 10.31 13.08 15.24 17.25 20.62 21.41 24.99 28.58 35.71

8.08 10.90 13.77 17.45 20.32 23.01 27.76 28.58 33.32 38.10 47.63

8.40 11.50 14.75 18.25 20.25 23.40 27.20 29.75 38.10 44.50 56.40

NPT

ANSI 94.9 : 1971

10

Nominal Diameter D

T. P. I.

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm) without reamer

1/8” 1/4” 3/8” 1/2” 3/4” 1” 1.1/4” 1.1/2” 2"

27 18 18 14 14 11.1/2 11.1/2 11.1/2 11.1/2

54.0 61.9 65.1 79.4 82.6 95.3 101.6 108.0 114.3

19.1 27.0 27.0 34.9 34.9 44.5 44.5 44.5 44.5

7.9 11.1 12.7 15.9 17.5 20.6 23.8 25.4 28.6

6.05 8.18 10.31 13.08 17.25 21.41 24.99 28.58 35.71

8.08 10.90 13.77 17.45 23.01 28.58 33.32 38.10 47.63

8.70 11.10 14.70 17.90 23.40 29.40 38.10 44.00 56.40

BA

BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

Pitch mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

12 11 10 9 8 7 6 5 4 3 2 1 0

0.28 0.31 0.35 0.39 0.43 0.48 0.53 0.59 0.66 0.73 0.81 0.90 1.00

41.3 41.3 41.3 42.9 44.5 46.0 47.6 49.2 50.8 54.0 60.3 60.3 63.5

7.9 7.9 7.9 9.5 11.1 12.7 14.3 15.9 17.5 19.1 22.2 22.2 25.4

4.8 4.8 4.8 4.8 4.8 4.8 4.8 4.8 4.8 6.4 6.4 6.4 7.1

2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.9 3.4 3.8 4.2 4.8

3.3 3.3 3.3 3.3 3.3 3.3 3.3 3.3 3.7 4.2 4.8 5.4 6.1

1.05 1.20 1.40 1.55 1.80 2.05 2.30 2.65 3.00 3.40 4.00 4.50 5.10

BSB

BS 949 : 1951

Nominal Diameter D

T. P. I. Inch

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/4” 5/16” 3/8” 7/16” 1/2” 9/16” 5/8” 3/4” 1"

26 26 26 26 26 26 26 26 26

63.5 69.9 74.6 76.2 76.2 76.2 76.2 82.6 82.6

25.4 28.575 31.75 31.75 31.75 31.75 31.75 38.1 38.1

7.1 8.7 10.3 10.3 11.1 12.7 14.3 17.5 20.6

5.0 6.1 7.5 6.1 7.0 8.2 9.1 11.2 15.2

6.4 8.0 9.6 8.2 9.3 10.9 12.2 15.0 20.3

5.30 6.90 8.40 9.90 11.50 13.10 14.65 17.86 17.86

11

BS CYCLE

BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

3/16” 1/4” 5/16” 3/8” 7/16” 1/2” 9/16” 9/16”

32 26 26 26 26 26 20 26

60.3 63.5 69.9 74.6 76.2 76.2 76.2 76.2

22.2 25.4 28.6 31.8 31.8 31.8 31.8 31.8

6.4 7.1 8.7 10.3 10.3 11.1 12.7 12.7

3.8 5.0 6.1 7.5 6.1 7.0 8.2 8.2

4.8 6.4 8.0 9.6 8.2 9.3 10.9 10.9

4.10 5.60 7.10 8.70 10.30 11.90 13.30 13.50

ME

BS 949 : 1951

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/8” 5/32” 3/16” 7/32” 1/4” 9/32” 5/16” 3/8”

40 40 40 40 40 32 32 32

49.2 54.0 60.3 60.3 63.5 63.5 69.9 74.6

15.9 19.1 22.2 22.2 25.4 25.4 28.6 31.8

4.8 6.4 6.4 6.4 7.1 7.9 8.7 10.3

2.7 3.1 3.8 4.4 5.0 5.6 6.1 7.5

3.3 4.0 4.8 5.6 6.4 7.2 8.0 9.6

2.55 3.25 4.10 4.90 5.80 6.10 7.10 8.60

BS CONDUIT BS 949 : 1951

12

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/2” 5/8” 3/4” 1” 1.1/4”

18 18 16 16 16

76.2 76.2 82.6 82.6 101.6

31.8 31.8 38.1 38.1 38.1

11.1 14.3 17.5 20.6 25.4

7.0 9.1 11.2 15.2 19.5

9.3 12.2 15.0 20.3 25.9

11.10 14.00 17.50 23.50 30.00

(U) NS

ANSI 94.9 : 1971

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

8 10 12 14 14 5/32” 5/32” 3/16” 3/16” 5/16” 11/16” 11/16” 1”

40 30 32 20 24 32 36 24 32 32 11 16 14

54.0 60.3 60.3 63.5 63.5 54.0 54.0 60.3 60.3 69.1 102.4 102.4 130.2

19.1 22.2 23.8 25.4 25.4 19.1 19.1 22.2 22.2 28.6 46.0 46.0 63.5

6.4 6.4 7.1 7.9 7.9 6.4 6.4 6.4 6.4 9.5 15.9 15.9 20.6

3.3 3.9 4.2 4.9 4.9 3.3 3.3 3.9 3.9 6.0 10.3 10.3 15.2

4.3 4.9 5.6 6.5 6.5 4.3 4.3 4.9 4.9 8.1 13.8 13.8 20.3

3.60 4.00 4.70 5.60 7.70 3.60 3.65 4.25 4.40 7.50 16.40 16.70 24.60

WHITWORTH FINE PITCH BS 949 : 1951

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/4” 5/16” 3/8”

32 40 40

63.5 69.9 74.6

25.4 28.6 31.8

7.1 8.7 10.3

5.0 6.1 7.5

6.4 8.0 9.6

5.60 7.30 8.90

13

BSPF

BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/8” 1/4” 3/8” 1/2” 5/8” 3/4” 7/8” 1" 1.1/4” 1.1/2” 1.3/4” 2"

28 19 19 14 14 14 14 11 11 11 11 11

54.0 61.9 65.1 79.4 81.0 82.6 88.9 88.9 101.6 108.0 111.1 114.3

19.1 27.0 27.0 34.9 34.9 34.9 39.7 44.5 44.5 44.5 44.5 44.5

7.9 11.1 12.7 15.9 17.5 17.5 19.1 20.6 23.8 25.4 27.0 28.6

6.0 8.2 10.3 13.1 15.2 17.2 20.6 21.4 25.0 28.6 30.9 35.7

8.1 10.9 13.8 17.4 20.3 23.0 27.8 28.6 33.3 38.1 41.3 47.6

8.80 11.80 15.25 19.00 21.00 24.50 28.25 30.75 39.50 45.00 51.00 57.00

NPS

ANSI 94.9 : 1971

14

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/8” 1/4” 3/8” 1/2” 3/4” 1”

27 18 18 14 14 11.1/2

54.0 61.9 65.1 79.4 82.6 95.3

19.1 27.0 27.0 34.9 34.9 44.5

7.9 11.1 12.7 15.9 17.5 20.6

6.0 8.2 10.3 13.1 17.2 21.4

8.1 10.9 13.8 17.4 23.0 28.6

9.10 11.90 15.25 19.00 27.00 30.50

Carbon Steel & High Speed Steel Circular Split Dies High Speed Steel Ground Dies Carbon Steel & High Speed Steel Die Nuts (Hexagonal Dies) Case Sets Tap Wrench & Die Stocks

15

BS 1127 : 1974

Carbon Steel & High Speed Steel Circular Split Dies

16

OD

THICKNESS

METRIC

Inch

Inch

13/16 "

1/4 “

mm 1.6 X 0.35 2.0 X 0.40 2.2 X 0.45 2.3 X 0.40 2.5 X 0.45 2.6 X 0.45 3.0 X 0.50 3.0 X 0.35, 0.60 3.5 X 0.60 4.0 X 0.35 , 0.50 4.0 X 0.70 4.0 X 0.75 4.5 X 0.50, 0.75 5 X 0.50, 0.75 5.0 X 0.80 5.0 X 0.90 5.5 X 0.50, 0.90 5.5 X 0.75 6.0 X 0.50, 0.75 6.0 X 1.00 7.0 X 0.75, 1.00

OD

THICKNESS

METRIC

Inch

Inch

1"

3/8”

mm 6.0 X 0.50, 0.75 6.0 x 1.00 7.0 X 0.75, 1.00 8.0 X 0.75, 1.00 8.0 X 1.25 9.0 X 0.75, 1.00 9.0 X 1.25 10 X 0.50, 0.75, 1.00 10 X 1.25 10 X 1.50

OD

THICKNESS

Inch

Inch

1.1/2 "

1/2”

BSW BSF Inch 1/16" 3/32" 1/8" 5/32" 3/16" 7/32" 1/4" -

UNC NS UNF No. / Inch No. / Inch 4 5 6 6 5/32" 8 8 11/64 " 10 & 3/16" 3/16" 12 12 & 7/32" 15/64" 1/4" 1/4" -

BSW BSF Inch 1/4" 9/32" 5/16" 3/8"

UNC UNF Inch 1/4" 5/16" 3/8"

NS

METRIC

BSW BSF

UNC UNF

NS

mm 11 X 1.00, 1.50 12 x ,1.00, 1.25 12 x 1.50 12 x 1.75 14 x 1.00, 1.25 14 x 1.50 14 x 2.00 15 x 1.50 16 x 1.00, 1.50 16 x 2.00 18 x 1.50 18 x 2.50 20 x 1.50, 2.50 20 x 1.50, 2.50

Inch 7/16 " 1/2 " 9/16 " 5/8 " 3/4 " -

Inch 7/16 " 1/2 " 9/16 " 5/8 " 3/4 " -

Inch 7/16 " 9/16 " 5/8 " 3/4 " -

Inch -

BSB BSCY Inch 3/16" 1/4" BSB BSCY Inch 1/4 9/32" 5/16" 3/8" BSB BSCY BSCON Inch 7/16 " 1/2 " 9/16 " 5/8 " 3/4 " -

ME

WF

BA

Inch 1/8" 5/32" 3/16" 7/32" 1/4" -

Inch 11/64 " 3/16 " 13/64 " 15/64 " 1/4 " -

No. 12 11 10 9 8 7 6 5 4 3 2 1 0 -

ME

WF

BSP

Inch 1/4" 9/32" 5/16" 3/8"

Inch 1/4" 9/32" 5/16" 3/8"

Inch 1/8 "

Pg

WF

BSP

No 7 X 20 9 x 18 11 x 18 13.5 x 18 13.5 x 18

Inch 7/16 " 1/2 " -

Inch 1/8" 1/4" 3/8" 1/2" 1/2”

BS 1127 : 1974

Carbon Steel & High Speed Steel Circular Split Dies

OD

THICKNESS

METRIC

BSW BSF

UNC UNF

NS

Inch

Inch

2"

5/8''

mm 20 x 1.50, 2.50 22 X 1.50 22 X 2.50 24 X 1.00, 1.50 24 X 3.00 25 x 1.50 26 x 1.50 27 x 1.50, 3.00 28 x 1.50 30 x 1.50, 3.50 25 x 1.50 26 x 1.50 27 x 1.50, 3.00 28 x 1.50 30 x 1.50, 3.50

Inch 1/2 " 9/16 " 5/8 " 3/4 " 7/8 " 1" -

Inch 1/2 " 9/16 " 5/8 " 3/4 " 7/8 " 1" -

Inch 9/16 " 5/8 " 3/4 " 7/8 " 1" -

OD Inch

THICKNESS Inch

2.1/4"

11/16''

2.1/2"

3"

4"

METRIC BSW/BSF UNC/UNF mm Inch Inch 27 x 3.00 30 x 3.50 1.1/8“ 1.1/8“ 32 x 1.50 1.1/4 “ 1.1/4“ 33 x 1.50, 3.50 -

BSB BSCY BSCON Inch 1/2 " 9/16 " 5/8 " 3/4 " 7/8 " 1" -

Pg

WF

BSP

No 16 x 18 21 x 16 21 x 16 -

Inch 1/2 " -

No. 1/4" 3/8" 1/2 " 5/8 " 3/4 " 7/8 " 1" 7/8 " 1" -

BSP Inch 7/8“ -

7/8''

34 x 1.50 35 x 1.50 36 x 1.50, 4.00 40 x 1.50

1.3/8 “ 1.1/2 “ -

1.3/8“ 1.1/2“ -

1.1/8“ 1.1/4“ -

7/8''

34 x 1.50 35 x 1.50 36 x 1.50, 4.00 38 x 1.50 39 x 4.00 42 x 4.50 45 x 1.50

1.1/2 “ -

1.1/2“ -

1.1/4“ -

1''

45 x 1.50 46 x 1.50 48 x 1.50, 5.00 50 x 1.50 52 x 1.50 55 x 1.50 60 x 1.50

1.3/4“ 2“ -

1.3/4“ 2“ -

1.3/8“ 1.1/2“ 1.3/4“ 2“ -

OD Inch 1" &1.1/2" 1.1/2" 1.1/2" & 2" 2" 2" & 2.1/2" 2.1/2" & 3" 3" 4" 4"

THICKNESS mm 10mm 14mm / 15mm 14mm / 15mm 19mm 20mm 25mm 25mm 25mm 27mm

BSPT / NPT Inch 1/8" 1/4" 3/8" 1/2" 3/4" 1" 1.1/4" 1.1/2" 2"

17

DIN 223

High Speed Steel Ground Dies

18

O.D. x THICKNESS in mm 16 x 5 16 x 5 16 x 5 20 x 5 20 x 5 20 x 5 20 x 5 20 x 5 20 x 7 20 x 7 20 x 7 20 x 7 20 x 7 25 x 9 25 x 9 25 x 9 25 x 9 30 x 11 30 x 11 30 x 11 38 x 10 38 x 10 38 x 10 38 x 10 38 x 10 38 x 10 38 x 14 38 x 14 45 x 14 45 x 14 45 x 14 45 x 14 45 x 14 45 x 18 45 x 18 45 x 18 55 x 16 55 x 16 55 x 22

SIZE in mm 1.6x0.45 2.5x0.45 2.6x0.45 3.0 x 0.50 3.5x0.60 4.0 x 0.70 4.5x0.75 5.0 x 0.80 6.0 x 0.50 6.0 x 0.75 6.0 x 1.00 7.0 x 0.75 7.0 x 1.00 8.00 x 0.75 8.00 x 1.00 8.00 x 1.25 10 x 1.00 10 x 1.25 10 x 1.50 12 x 1.00 12 x 1.25 12 x 1.50 14 x 1.00 14 x 1.25 14 x 1.50 12 x 1.75 14 x 2.00 16 x 1.00 16 x 1.50 20 x 1.00 20 x 1.50 20 x 2.00 16 x 2.00 18 x 2.50 20 x 2.50 22 x 1.50 24 x 1.50 24 x 3.00

BSW/BSF No./Inch 5/32” 3/16 “ 1/4 “ 5/16 “ 3/8 “ 7/16 “

UNC/UNF No./Inch 4 5 6 8 10 12 1/4 “ 5/16 “ 3/8 “ 7/16 “

1/2 “ 9/16 “ 5/8” 3/4” -

1/2 “ 9/16 “ 5/8” 3/4” -

BA No. 6 4 2 -

BSP Inch 1/8 “ 1/4 “ 3/8” 1/2” -

BS 1127:1974

Carbon Steel & High Speed Steel Die Nuts

A/F

METRIC

BSW/BSF

UNC/UNF

BSP

Inch

in mm

Inch

Inch

Inch

0.710 “

3 to 6

1/8 “ to 1/4”

1/4”

-

0.820 “

7 to 8

5/16 “

5/16 “

-

0.920 “

9 to 10

3/8 “

3/8 “

1/8 “

1.010 “

11

7/16 “

7/16 “

-

1.100 “

12 to 13

1/2 “

1/2 “

1/4 “

1.300 “

14 to 16

9/16 “ & 5/8 “

9/16 “ & 5/8 “

3/8 “

1.480 “

18 to 20

11/16 “ & 3/4 “

3/4 “

-

1.670 “

21 to 22

7/8 “

7/8 “

1/2”& 5/8”

2.050 “

24 to 26

1“

1“

3/4 “

2.220 “

27 to 32

1.1/8 “ & 1.1/4 “

1.1/8 “ & 1.1/4 “

7/8 “

2.580 “

33 to 35

1.3/8 “

1.3/8 “

1“

2.760 “

36 to 40

1.1/2 “

1.1/2 “

1.1/4 “

3.150 “

42 to 48

1.3/4 “

1.3/4 “

1.1/2 “

3.550 “

50 to 52

2“

2“

1.3/4 “

3.890 “

55 to 56

2.1/4 “

2.1/4 “

2“

19

ACCESSORIES

Tap and Die Case Sets

20

Ref. NO: METRIC 1 Taps (Second) Dies Accessories

No. of Pieces : 20 M6, M8, M10, M12, M14, M16, M20 1’’ OD - M6 to M10 & 1.1/2’’ OD - M12 to M20 Tap Wrenches - 2nos. & Die Stock - 2nos.

Ref. NO: METRIC 2 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 28 M6, M8, M10, M12, M14, M16, M20 1’’ OD - M6 to M10 & 1.1/2’’ OD - M12 to M20 Tap Wrenches - 2nos. & Die Stock - 2nos.

Ref. No: C 119 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 37 M6, M7,M8, M9, M10, M11, M12, M14, M16, M20 1’’ OD - M6 to M10 & 1.1/2’’ OD - M11 to M20 Tap Wrenches - 2no. & Die Stock - 2nos.

Ref. No: METRIC 3 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 21 M3, M4, M5, M6, M8, M10 13/16’’ OD - M3 to M5 & 1’’ OD - M6 to M10 Tap Wrenches - 1no. & Die Stock - 2nos.

Ref. No: METRIC 4P Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 17 M2, M3, M4, M5, M6, 13/16’’ OD - M2 to M6 Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: METRIC 4S Taps (Taper, Second, Bottom) Dies Accessories

No. of Pieces : 22 M2, M3, M4, M5, M6, 13/16’’ OD - M2 to M6 Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: METRIC 5F Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 35 MF6, MF8, MF10, MF12, MF14, MF16, MF18, MF20, M22, M24 1’’ OD - MF6 to MF10 + 1.1/2’’ OD - MF12 to MF20 + 2’’ OD - MF22 to MF24 Tap Wrenches - 2nos. & Die Stock - 3nos.

Ref. No: C 120 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 35 M6, M7,M8, M9, M10, M11, M12, M14, M16, M20, M22, M24 1’’ OD - M6 to M10 + 1.1/2’’ OD - M11 to M16 + 2’’ OD - M18 to M24 Tap Wrenches - 2nos. & Die Stock - 3nos.

Ref. No: METRIC 5C Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 35 M6, M8, M10, M12, M14, M16, M18, M20, M22, M24 1’’ OD - M6 to M10 + 1.1/2’’ OD - M12 to M20 + 2’’ OD - M22 to M24 Tap Wrenches - 2nos. & Die Stock - 3nos.

Ref. No: METRIC 6P Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 24 M3, M4, M5, M6, M8, M10, M12 1’’ OD - M3 to M12 Tap Wrenches - 2nos. & Die Stock - 1no.

Ref. No: METRIC 6S Taps (Taper, Second, Bottom) Dies Accessories

No. of Pieces : 31 M3, M4, M5, M6, M8, M10, M12 1’’ OD - M3 to M12 Tap Wrenches - 2nos. & Die Stock - 1no.

ACCESSORIES

Tap and Die Case Sets

Ref. No: C 114 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 36 M2, M3, M4, M5, M6, M7,M8, M9, M10, M11, M12 13/16’’ OD - M2 to M6 + 1’’ OD - M7 to M12 Tap Wrenches - 1no. & Die Stock - 2nos.

Ref. No: METRIC 7 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 18 M6, M8, M10, M11, M12 1’’ OD - M6 to M10 + 1.1/2’’ OD - M11, M12 Tap Wrenches - 1no. & Die Stock - 2nos.

Ref. No: C 118 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 23 M6, M7,M8, M9, M10, M11, M12 1’’ OD - M6 to M12 Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: METRIC 8 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 23 M3, M4, M5, M6, M8, M10, M12 1’’ OD - M3 to M12 Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: C 37 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 24 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’, 5/8’’, 3/4’’ 1’’ OD - 1/4’’, 5/16’’, 3/8’’ + 1.1/2’’ OD - 7/16’’, 1/2’’, 5/8’’, 3/4’’ Tap Wrenches - 1no. & Die Stock - 2nos.

Ref. No: INCH 9 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 28 1/4’’, 5/16’’, 3/8’’, 1/2’’, 9/16’’, 5/8’’, 11/16’’, 3/4’’ 1’’ OD - 1/4’’, 5/16’’, 3/8’’ + 1.1/2’’ OD - 9/16’’, 5/8’’, 11/16’’, 3/4’’ Tap Wrenches - 2no. & Die Stock - 2nos.

Ref. No: C 31 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 24 1/8’’, 3/16’’, 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’ 13/16’’ OD - 1/8’’, 3/16’’ + 1’’ OD - 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’ Tap Wrenches - 1no. & Die Stock - 2nos.

Ref. No: C 82 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 17 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’ 1’’ OD - 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’ Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: C 52 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 20 3/16’’, 5/16’’, 1/4’’, 3/8’’, 7/16’’, 1/2’’ 1’’ OD - 3/16’’, 5/16’’, 1/4’’, 3/8’’, 7/16’’, 1/2’’ Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: C 85 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 32 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’, 5/8’’, 3/4’’, 7/8’’, 1’’ 1’’ OD - 1/4’’, 5/16’’, 3/8’’ + 1.1/2’’ OD - 7/16’’, 1/2’’, 5/8’’ + 2’’ OD - 3/4’’, 7/8’’, 1’’ Tap Wrenches - 2nos. & Die Stock - 3nos.

21

ACCESSORIES

Tap Wrench and Die Stocks

TAP CAPACITY Inch 1/16”-1/4” 1/8”-1/2” 5/32”-3/8” 3/16”-1/2” 3/16”- 5/8”

ADJUSTABLE TAP WRENCHES (ZINC DIE CAST BODY) TAP CAPACITY OVERALL NOMINAL LENGTH mm Inch 2 - 6 MM 7” 4 - 10 MM 9” 4 - 10 MM 9” 5 - 12 MM 11-3/16” 5 - 12 MM 11-3/16”

OVERALL NOMINAL LENGTH mm 180 230 230 285 285

TAP CAPACITY Inch 1/16"-1/4" 1/8"-1/2" 5/32"-3/8" 3/16"-1/2" 3/16"- 5/8" 1/4" - 3/4" 5/16" - 1" 3/8" - 1"

ADJUSTABLE TAP WRENCHES (FORGED STEEL) TAP CAPACITY OVERALL NOMINAL LENGTH mm Inch 2-6 MM 6 - 1/4'' 4-10 MM 8 4-10 MM 8 5-16 MM 10 - 1/4'' 5-16 MM 10 - 1/4'' 6-20 MM 13 - 1/4'' 8-25 MM 18 - 1/4'' 8-25 MM 18 - 1/4''

OVERALL NOMINAL LENGTH mm 170 200 200 260 260 343 465 465

TAP CAPACITY Inch 1/16"-5/32" 5/32" - 1/4" 3/16" - 5/16" 1/4" - 1/2"

TAP CAPACITY mm 2 - 4 MM 4 - 6 MM 5 - 8 MM 6 - 12 MM

T HANDLE TAP WRENCHES OVERALL NOMINAL LENGTH Inch 2-3/8" 2-11/16" 3 - 5/32" 3 - 1/2"

OVERALL NOMINAL LENGTH mm 60 MM 69 MM 80 MM 88 MM

TAP CAPACITY Inch 5/32" - 1/4" 1/4" - 1/2"

T HANDLE TAP WRENCHES RACHET TYPE TAP CAPACITY OVERALL NOMINAL LENGTH mm Inch 4 - 6 MM 2-11/16" 6 - 12 MM 3 - 1/2"

OVERALL NOMINAL LENGTH mm 69 MM 88 MM

DIE STOCKS

22

CAPACITY O/D THREADING DIES Inch mm 5/8” 15 13/16” 20 1” 25 1-5/16” 33 1-1/2” 38 2” 50 2-1/4” 57 2-1/2” 63 3” 75 4” 100

OVERALL NOMINAL LENGTH Inch 5-1/2” 6-3/4” 8-3/4” 10” 12-1/2” 15-9/16” 16-1/2” 19” 22-1/2” 35”

*Tap Wrench and Die Stocks are supplied in export markets only.

OVERALL NOMINAL LENGTH mm 140 MM 170 MM 222 MM 254 MM 317 MM 395 MM 420 MM 480 MM 572 MM 890 MM

Tap and Die Terminology Lead / Chamfer: The taper at the thread end of the tap or

the throat of the die, made by cutting away the crests of the first few threads is to distribute the work of cutting, over several threads and act as guide in starting the tap or die. The chamfer is relieved to facilitate cutting. The tap is classed as Taper, Second or Bottoming according to the length of chamfer which approximate to the following :

For Taps

1. Taper Tap……....…4° per side (10 to 12 threads)

2. Second Tap….....…8° per side (6 to 8 threads)

3. Bottoming Tap…...22° per side (1.1/2 to 2.1/2 threads)

For Dies

1. Stamped side………45°

2. Back side……………60°

Clearance Hole: The holes in the die that provide the cutting rake and chip clearance. Effective Diameter: The pitch circle diameter of thread as generated by the straight line parallel to axis of the tap.

This straight line is called as pitch line. Along the pitch line the width of the thread and width of spaces are equal on a perfect thread. Flute: The grooves in the tap that provide the cutting rake and chip clearance. Helix angle: The angle made by helix of a thread at the pitch diameter with a plane perpendicular to the axis. The

helix angle increases continuously from the crest to the root of the thread. Land, Land width: It is the face between the cutting edge and the non cutting edge. Web: The central portion of the tap which s the land and extending along flute portion of the tap. Lead / Pitch: The distance a screw thread advanced axially in one complete turn. On a single thread the lead and

the pitch are identical. Major Diameter: The largest diameter on a parallel screw thread or tap. The term “Major Diameter” is a replacement

for the term “Outside Diameter” as applied to the thread of a screw and also the term “Full Diameter” as applied to the thread of a nut. Minor Diameter: The smallest diameter on a parallel screw thread or tap. The term “Minor Diameter” is a replacement

for the term “Core Diameter” and “Root Diameter” as applied to the thread of a screw and also the term “Inside Diameter” as applied to the thread of a nut. Number of Threads / TPI: The number of threads in a length of one inch.

23

Applications of Taps & Dies Automobile Industry Cylinder liner and Cylinder head manufacturers General purpose applications in small workshops, garages, tool rooms and maintenance departments Motor cycle body frames: Spatter cleaning and removing paint from threaded portion. Carburetor and speedometer manufacturers High Speed Steel Dies are used in removing paint from threaded portion in rear axles of cars, trucks, buses, etc. Dies are used by gas valve manufacturers.

Engineering Industry Air Compressors / Blower manufacturers Cooling towers and heat exchangers Brass component manufacturers Pipe and Pipe fitting manufacturers. Sheet Metal Industry Thread dressing of diesel engine components Steel furniture manufacturers Steel window manufacturers Bus and Truck body building workshops Textile industry Electrical industry

Household appliance manufacturers Pressure cookers Fans, Air coolers, Air conditioners Flour mills, Mixers and Grinders

24

Totem Range Of Products HIGH SPEED STEEL GROUND THREAD TAPS.

Range: 1.6mm – 120mm, 1/16’’ – 3’’ . Higher dimensions can be manufactured as per order.

Surface Treatment: TiN/TiCN/TiAIN/Steam Tempered

Material: HSS – M2 Steel and HSSE M 35 / M 42 Steel

Thread Forms: BSW/BSF/UNF/UNC/MM/BA/BSP/BSPT/BSCY/WF/ ME/BSCON/NPT/NGT/ACME.

Variety: Hand Taps, Machine Taps – Straight Flute, Spiral Flute, Spiral Point, Fluteless

SOLID CARBIDE END MILLS (SQUARE AND BALL NOSE)

Material: Ultrafine grade 12% Cobalt Carbide and micro grain 10% Cobalt Carbide.

Size Range: 1mm to 32mm (and equivalent sizes in inches)

Surface Treatment: TiN/TiCN/TiAIN/Steam Tempered

Variety: Available in 2, 3 and 4 Flute geometries

SOLID CARBIDE DRILLS

Jobber Drills available in size range 1mm to 20mm Ideal for Cast Iron, Aluminium, Bronze and Magnesium alloys. Hi – Tuff Drills available in size range 1mm to 20mm Ideal for Stainless Steel, Tool Steel, Titanium and Nickel based alloys.

Through Coolant Drills available in size range 4mm to 20mm

Ideal for deep hole drilling on medium / low Carbon steel,

Cast Iron, Stainless Steel and Aluminium.

TUNGSTEN CARBIDE ROTARY BURRS

Size Range: 1.5mm to 25mm Head Diameter and Shank Diameter 3mm, 6mm, 8mm, 1/8”, 1/4”.

Type of cuts: Single Cut, Double Cut, Diamond Cut, Aluma Cut and Chip breaker

25

and Conditions

Prices: Prices are subjct to revision. For local sales price please your nearest local sales office. For export sales price please at : [email protected] Payment: In case of local sales goods will be sold as per the standard price list and agreed and conditions. In case of export sales the preferred mode of payment will be in advance or against irrevocable and confirmed documentary credit to be opened in our favour with an Indian bank. All banking commission and charges have to be borne by the customer. Right of ownership: We reserve the right of ownership of all goods supplied until the sale price, plus all incidental charges have been fully cleared. Despatch: Deliveries take place at the purchaser’s risk. Delivery: Confirmed delivery dates are non-binding. We will take due care to maintain these dates. However we cannot accept responsibility of direct or consequential losses due to delayed deliveries. Special orders: For all special tools we reserve the right to over or under supply the ordered quantity by up to 10%. Guarantee: Tools recognised to be defective by the company will be replaced free of charge but without prejudice. DAMAGE,SHORTAGE OR LOSS: The Seller shall not be under liability in respect of damage, shortage or loss of the goods in respect of which the Seller has not be notified in writing within 3 days after receipt of the goods by the Buyer. Drawings and sketches: The reproduction of transmission of drawings and other documents to a third party are prohibited. The information (drawings and prints) in our catalogue is for guidance only and is not binding. Special conditions: In the case of partial or total disruption of our production: we reserve the right to partially or totally cancel our delivery commitments. The range shown in the catalogue is for reference purpose only and we do not essentially stock all the items. Please respective marketing department for delivery and price. Tribunal: All disputes are subject to Indian Law. All cases will subject to fall within the jurisdiction of Mumbai.

26

Warning: Any cutting tool may break or shatter if improperly used. We recommend use of safety accessories like glasses, gloves, etc. at all times in the vicinity of use. Grinding of taps or dies may produce hazardous dust and should only be done under established safety guidelines.

EXPORTING TO : North America: USA, Mexico, West Indies, Canada

Middle East: Turkey, Lebanon, Kuwait, UAE, Saudi Arabia, Iran

South America: Chile, Columbia, Uruguay

West Asia: Pakistan, Sri Lanka, Bangladesh

Europe: UK, , Poland, Russia

South East Asia: Thailand, Vietnam, Malaysia, Indonesia

Africa: Egypt, Kenya, Tanzania, South Africa

Far East : Australia and New Zealand

For Export enquiries write to us on: [email protected] or Fax at 91-22-28473191.

SALES OFFICES IN INDIA Ahmedabad 1st Floor, Pran Vijay, Near Times Of India, Ashram Road-Pin 380009. Tel: 079-26587769 Fax: 079-26584618 E.mail : [email protected] Kolkata

222, AJC Bose Road, Circular Centre, Flat 1&2, 1st Floor, Pin – 700 017 Tel: 033-2267 3076 Fax: 033-2289 1311

Mumbai

* INDORE

Saki Powai Road, Chandivali, Pin – 400 072 Tel: 022-2847 1861 Fax: 022-2847 1799 E.mail : [email protected]

204, N28, Anoop Nagar, Indore (M.P.) Pin-452 008. Tel: 09826906346 E.mail : [email protected]

New Delhi

Tel: 09838004355 E.mail : [email protected]

9/10-3, Asaf Ali Road, Pin – 110 002 Tel: 011-4300 0120/9 Fax 011-4300 0130 E.mail : [email protected]

* Ludhiana

Pune

* Kanpur

237, Jagjit Nagar, Threeka Road, Near Rajguru Nagar, Pin-142 021. Tel: 09815165982 E.mail : [email protected]

1/12, Annapurna, Karve Road, Opp. S. N. D. T. College, Erandawane, Pin – 411 004. Tel: 020-2546 6442 Fax: 020-2546 6286 E.mail : [email protected]

* Rajkot

* BARODA

* Secunderabad

12/190, MIG Flats, Karelibaug, Baroda, Pin-390 018. Tel: 09825917524 E.mail : [email protected]

5th Floor, P.V.S. Mansion, Somasundaram Street, Beside Manju Theatre, Sarojinidevi Road, Pin-500 003. Tel: 040-2781 4585 Fax: 040-2784 4967 Mobile : 09885260611 E.mail : [email protected]

* Chandigarh

186, Puskardham Society “Nimal” Nr. Alap Avenue, University Road, Pin – 360005 Tel: 09924127754 E.mail : [email protected]

House No. 527, Sector 11B, Pin-160011. Tel: 09417028106 E.mail : [email protected] * Residential Representatives

For all domestic inquiries write to us on [email protected] or fax at 91-22-28473191.

Designed & Printed by : Spenta Multimedia: 91-22-24811010

FORBES PRECISION TOOLS

Saki Powai Road, Chandivali, Mumbai – 400 072. Tel: 91-22-28471861, 28471298 Fax : 91-22-2847 1799 / 2847 3191 A-7/1, MIDC Area, Chikalthana, Aurangabad-431210 Tel: 91-240-2485226 Fax: 91-240-2485058

www.totem-forbes.com

World class threading tools from

2009

Forbes Precision Tools manufactures High Speed Steel Threading Taps and Dies, Carbon Steel Threading Taps and Dies, Tungsten Carbide Rotary Burrs, Solid Carbide Tools and Spring Washer. Forbes Precision Tools is a part of FORBES & COMPANY LTD., which was started in 1767. This division began its manufacturing during 1963 in collaboration with Nuckey Scott & Company Ltd. UK, the manufacturers of world famous “WARRIOR” brand of threading tools. The manufacturing of Tungsten Carbide Burrs began in 1968 with the technical knowhow from B.O. Morris, U.K. Solid Carbide tools manufacturing began in 1997 under t operation with M.A. Ford, USA. We hold leadership position in India. Our tools are manufactured and sold under “TOTEM” brand name. ‘TOTEM’ is committed to being the leading manufacturer with quality and reliability for its customers. The tools are manufactured on latest CNC machines with strict quality procedures and skilled technical team. Continuous investments are made in research and development to keep pace with the latest technology. At FORBES, the endeavour continue….

Quality Policy We commit ourselves to the enhancement of customer satisfaction and maintaining global market presence by development, manufacturing and marketing of excellent products. This involves continual improvement of processes, participation of employees and suppliers.

Strategic quality objectives 1. To enhance customer satisfaction by –

A. Consistent quality.

B. On time delivery.

C. Prompt after sales service.

D. Focus on evolving needs of customer.

2. Education, training and development of employees to enable them to utilise their full potential in meeting company objectives which are as follows :

A. To enhance cost effectiveness of company by identifying and

eliminating non value added activities.

B. Technology up gradation by reconditioning, retrofitting and innovation.

G. Mukharji (Director - Engineering)

A Product of Total Engineering Excellence

Q

uality: All tools are manufactured from first-grade high Carbon Steel and High Speed Steel and are designed to meet the most stringent engineering demands.

H

eat Treatment: All tools are heat treated in atmospheric controlled furnaces with modern timers and temperature controllers which are strictly calibrated periodically to ensure correct heat treatment of tools with no decarb.

I

nspection: Every tool we supply es through stringent inspection tests. Our factory is equipped with the most modern and precise equipments, which are periodically calibrated.

F

inish: A high level of finish is maintained in keeping with the requirements of a precision cutting tool.

P

resentation: All tools are packed in attractive boxes distinctly labeled with Holograms.

S T

olerances: Thread to Zone 5 of BS 949: 1951.

tandards: Carbon Steel taps are manufactured as per British Standard BS 949: 1951 and American standard ANSI 94.9: 1971. Dies and Die Nuts are manufactured as per British Standard BS 1127: 1974

T

hread direction: All tools are supplied for Right Hand screwing. Tools for Left Hand screwing can also be supplied against requirement.

INDEX PRODUCT SPECIFICATIONS

PAGE NO.

CARBON STEEL TAPS Metric Coarse

06

Metric Fine

07

BSW/BSF

08

UNC/UNF

09

BSPT/NPT

10

BA/BSB

11

BS CYCLE/ME/BS CONDUIT

12

UNS/WHITWORTH FINE

13

BSPF/NPS

14

CIRCULAR SPLIT DIES CARBON STEEL AND HIGH SPEED STEEL

16-17

HIGH SPEED STEEL GROUND DIES

18

HEXAGONAL DIES / DIE NUTS

19

CARBON STEEL AND HIGH SPEED STEEL TAP AND DIE CASE SETS

20-21

Tap Wrench and Die Stocks

22

Tap and Die terminology

23

Application of products

24

“TOTEM” range of products

25

and Conditions

26

METRIC COARSE BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

6

Nominal Diameter D

Pitch mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

2.0 2.2 2.5 3.0 3.5 4.0 4.5 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 12.0 14.0 14.0 16.0 18.0 20.0 22.0 24.0 27.0 30.0 33.0 36.0 39.0 42.0 45.0 48.0 52.0

0.40 0.45 0.45 0.50 0.60 0.70 0.75 0.80 1.00 1.00 1.25 1.25 1.50 1.50 1.50 1.75 1.50 2.00 2.00 2.50 2.50 2.50 3.00 3.00 3.50 3.50 4.00 4.00 4.50 4.50 5.00 5.00

42.9 44.5 46.0 47.6 50.8 54.0 60.3 60.3 63.5 63.5 69.9 74.6 74.6 80.2 85.7 85.7 91.3 91.3 96.8 102.4 108.0 119.1 124.6 130.2 138.1 146.1 154.0 161.9 169.9 177.8 185.7 193.7

9.5 11.1 12.7 14.3 17.5 19.1 22.2 22.2 25.4 25.4 28.6 31.8 31.8 36.5 42.1 42.1 42.1 42.1 46.0 46.0 50.8 56.4 56.4 63.5 65.1 65.1 76.2 76.2 81.0 81.0 90.5 90.5

4.8 4.8 4.8 4.8 4.8 6.4 6.4 6.4 7.1 7.9 8.7 10.3 10.3 10.3 11.1 11.1 12.7 12.7 14.3 15.9 17.5 19.1 19.1 20.6 22.2 25.4 27.0 28.6 28.6 31.8 31.8 31.8

2.7 2.7 2.7 2.7 2.9 3.4 3.8 4.2 4.8 5.6 6.3 7.0 7.8 6.1 7.0 7.0 8.2 8.2 9.1 10.3 11.2 13.3 14.5 15.2 17.1 19.5 21.1 23.5 24.9 27.2 28.9 28.9

3.3 3.3 3.3 3.3 3.7 4.2 4.8 5.4 6.1 7.2 8.2 9.1 10.3 8.2 9.3 9.3 10.9 10.9 12.2 13.8 15.0 17.7 19.3 20.3 22.8 25.9 28.1 31.3 33.1 36.3 38.6 38.6

1.60 1.75 2.05 2.50 2.90 3.30 3.70 4.20 5.00 6.00 6.80 7.80 8.50 9.50 10.50 10.20 12.50 12.00 14.00 15.50 17.50 19.50 21.00 24.00 26.50 29.50 32.00 35.00 37.50 40.50 43.00 47.00

METRIC FINE BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

Pitch mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

2.30 2.60 3.00 4.00 4.00 5.00 5.00 5.50 6.00 8.00 8.00 9.00 10.00 10.00 10.00 12.00 12.00 14.00 16.00 18.00 20.00 22.00 24.00 25.00 26.00 27.00 28.00 30.00 30.00 32.00 40.00

0.40 0.45 0.60 0.50 0.75 0.50 0.90 0.90 0.75 0.75 1.00 1.00 0.75 1.00 1.25 1.00 1.25 1.25 1.00 1.50 1.00 1.50 1.50 1.50 1.50 1.50 1.50 1.50 2.00 1.50 1.50

44.5 47.6 47.6 54.0 54.0 60.3 60.3 60.3 63.5 69.9 69.9 74.6 74.6 74.6 74.6 76.2 76.2 76.2 76.2 76.2 82.6 82.6 82.6 82.6 82.6 82.6 101.6 101.6 101.6 101.6 101.6

11.1 14.3 14.3 19.1 19.1 22.2 22.2 22.2 25.4 28.6 28.6 31.8 31.8 31.8 31.8 31.8 31.8 31.8 31.8 31.8 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1 38.1

4.8 4.8 4.8 6.4 6.4 6.4 6.4 6.4 7.1 8.7 8.7 10.3 10.3 10.3 10.3 11.1 11.1 12.7 14.3 15.9 17.5 19.1 19.1 20.6 20.6 20.6 20.6 22.2 22.2 25.4 28.6

2.7 2.7 2.7 3.4 3.4 4.2 4.2 4.4 4.8 6.3 6.3 7.0 7.8 7.8 7.8 7.0 7.0 8.2 9.1 10.3 11.2 13.3 14.5 15.2 15.2 15.2 15.9 17.1 17.1 19.5 23.5

3.3 3.3 3.3 4.2 4.2 5.4 5.4 5.6 6.1 8.2 8.2 9.1 10.3 10.3 10.3 9.3 9.3 10.9 12.2 13.8 15.0 17.7 19.3 20.3 20.3 20.3 21.2 22.8 22.8 25.9 31.3

1.90 2.10 2.40 3.50 3.25 4.50 4.10 4.60 5.20 7.20 7.00 8.00 9.20 9.00 8.80 11.00 10.75 12.75 15.00 16.50 19.00 20.50 22.50 23.50 24.50 25.50 26.50 28.50 28.00 31.50 38.00

7

BSW / BSF

BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

8

Nominal Diameter D

T.P.I. (BSW)

1/16” 3/32” 1/8” 5/32” 3/16” 7/32” 1/4” 9/32” 5/16” 3/8” 7/16” 1/2” 9/16” 5/8” 11/16” 3/4” 13/16” 7/8” 15/16” 1" 1-1/8" 1-1/4" 1-3/8" 1-1/2" 1-3/4" 2"

60 48 40 32 24 24 20 20 18 16 14 12 12 11 11 10 10 9 9 8 7 7 6 6 5 4.1/2

T.P.I. (BSF)

L mm

I mm

I1 mm

a mm

d mm

32 28 26 26 22 20 18 16 16 14 14 12 12 11 11 10 9 9 8 8 7 7

41.3 46.0 49.2 54.0 60.3 60.3 63.5 63.5 69.9 74.6 80.2 85.7 91.3 96.8 102.4 108.0 113.5 119.1 124.6 130.2 138.1 146.1 154.0 161.9 177.8 193.7

7.9 12.7 15.9 19.1 22.2 22.2 25.4 25.4 28.6 31.8 36.5 42.1 42.1 46.0 46.0 50.8 50.8 56.4 56.4 63.5 65.1 65.1 76.2 76.2 81.0 90.5

4.8 4.8 4.8 6.4 6.4 6.4 7.1 7.9 8.7 10.3 10.3 11.1 12.7 14.3 15.9 17.5 17.5 19.1 19.1 20.6 22.2 25.4 27.0 28.6 31.8 34.9

2.7 2.7 2.7 3.1 3.8 4.4 5.0 5.6 6.1 7.5 6.1 7.0 8.2 9.1 10.3 11.2 12.4 13.3 14.5 15.2 17.1 19.5 21.1 23.5 27.2 31.3

3.3 3.3 3.3 4.0 4.8 5.6 6.4 7.2 8.0 9.6 8.2 9.3 10.9 12.2 13.8 15.0 16.6 17.7 19.3 20.3 22.8 25.9 28.1 31.3 36.3 41.8

Tapping drill sizes (BSW) mm 1.20 1.90 2.55 3.20 3.70 4.50 5.10 5.80 6.50 7.90 9.30 10.50 12.10 13.50 15.00 16.25 18.00 19.25 21.00 22.00 24.75 28.00 31.00 33.50 39.00 44.50

Tapping drill sizes (BSF) mm

4.00 4.60 5.30 6.10 6.80 8.30 9.70 11.10 12.70 14.00 15.50 16.75 18.50 19.75 21.00 22.75 25.50 28.50 31.50 34.50 40.50 46.80

(U) NC / (U) NF ANSI 94.9 : 1971

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

T.P.I. (U)NC

T.P.I. (U)NF

L mm

I mm

I1 mm

a mm

d mm

0 1 2 3 4 5 6 8 10 12 1/4” 5/16” 3/8” 7/16” 1/2” 9/16” 5/8” 3/4” 7/8” 1" 1-1/8" 1-1/4" 1-3/8" 1-1/2" 1-3/4" 2"

– 56 56 48 40 40 32 32 24 24 20 18 16 14 13 12 11 10 9 8 7 7 6 6 5 4.1/2

80 72 64 56 48 44 40 36 32 28 28 24 24 20 20 18 18 16 14 12 12 12 12 12 – –

41.3 42.9 44.5 46.0 47.6 49.2 50.8 54.0 60.3 60.3 63.5 69.1 74.6 80.2 85.7 91.3 96.8 108.0 119.1 130.2 138.1 146.1 154.0 161.9 177.8 193.7

7.9 9.5 11.1 12.7 14.3 15.9 17.5 19.1 22.2 23.8 25.4 28.6 31.8 36.5 42.1 42.1 46.0 50.8 56.4 63.5 65.1 65.1 76.2 76.2 81.0 90.5

4.8 4.8 4.8 4.8 4.8 4.8 4.8 6.4 6.4 7.1 7.9 9.5 11.1 10.3 11.1 12.7 14.3 17.5 19.1 20.6 22.2 25.4 27.0 28.6 31.8 34.9

2.8 2.8 2.8 2.8 2.8 2.8 2.8 3.3 3.9 4.2 4.9 6.0 7.3 6.1 7.0 8.2 9.1 11.2 13.3 15.2 17.1 19.5 21.1 23.5 27.2 31.3

3.6 3.6 3.6 3.6 3.6 3.6 3.6 4.3 4.9 5.6 6.5 8.1 9.7 8.2 9.3 10.9 12.2 15.0 17.7 20.3 22.8 25.9 28.1 31.3 36.3 41.8

Tapping Tapping Drill Sizes Drill sizes ((U)NC) mm ((U)NF) mm – 1.55 1.85 2.10 2.35 2.65 2.85 3.50 3.90 4.50 5.10 6.60 8.00 9.40 10.80 12.20 13.50 16.50 19.50 22.25 25.00 28.00 30.75 34.00 39.50 45.00

1.25 1.55 1.90 2.15 2.40 2.70 2.95 3.50 4.10 4.70 5.50 6.90 8.50 9.90 11.50 12.90 14.50 17.50 20.40 23.25 26.50 29.50 32.75 36.00 – –

9

BSPT

BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

T. P. I.

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm) without reamer

1/8” 1/4” 3/8” 1/2” 5/8” 3/4” 7/8” 1” 1.1/4” 1.1/2” 2"

28 19 19 14 14 14 14 11 11 11 11

54.0 61.9 65.1 79.4 81.0 82.6 88.9 95.3 101.6 108.0 114.3

19.1 27.0 27.0 34.9 34.9 34.9 39.7 44.5 44.5 44.5 44.5

7.9 11.1 12.7 15.9 17.5 17.5 19.1 20.6 23.8 25.4 28.6

6.05 8.18 10.31 13.08 15.24 17.25 20.62 21.41 24.99 28.58 35.71

8.08 10.90 13.77 17.45 20.32 23.01 27.76 28.58 33.32 38.10 47.63

8.40 11.50 14.75 18.25 20.25 23.40 27.20 29.75 38.10 44.50 56.40

NPT

ANSI 94.9 : 1971

10

Nominal Diameter D

T. P. I.

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm) without reamer

1/8” 1/4” 3/8” 1/2” 3/4” 1” 1.1/4” 1.1/2” 2"

27 18 18 14 14 11.1/2 11.1/2 11.1/2 11.1/2

54.0 61.9 65.1 79.4 82.6 95.3 101.6 108.0 114.3

19.1 27.0 27.0 34.9 34.9 44.5 44.5 44.5 44.5

7.9 11.1 12.7 15.9 17.5 20.6 23.8 25.4 28.6

6.05 8.18 10.31 13.08 17.25 21.41 24.99 28.58 35.71

8.08 10.90 13.77 17.45 23.01 28.58 33.32 38.10 47.63

8.70 11.10 14.70 17.90 23.40 29.40 38.10 44.00 56.40

BA

BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

Pitch mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

12 11 10 9 8 7 6 5 4 3 2 1 0

0.28 0.31 0.35 0.39 0.43 0.48 0.53 0.59 0.66 0.73 0.81 0.90 1.00

41.3 41.3 41.3 42.9 44.5 46.0 47.6 49.2 50.8 54.0 60.3 60.3 63.5

7.9 7.9 7.9 9.5 11.1 12.7 14.3 15.9 17.5 19.1 22.2 22.2 25.4

4.8 4.8 4.8 4.8 4.8 4.8 4.8 4.8 4.8 6.4 6.4 6.4 7.1

2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.9 3.4 3.8 4.2 4.8

3.3 3.3 3.3 3.3 3.3 3.3 3.3 3.3 3.7 4.2 4.8 5.4 6.1

1.05 1.20 1.40 1.55 1.80 2.05 2.30 2.65 3.00 3.40 4.00 4.50 5.10

BSB

BS 949 : 1951

Nominal Diameter D

T. P. I. Inch

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/4” 5/16” 3/8” 7/16” 1/2” 9/16” 5/8” 3/4” 1"

26 26 26 26 26 26 26 26 26

63.5 69.9 74.6 76.2 76.2 76.2 76.2 82.6 82.6

25.4 28.575 31.75 31.75 31.75 31.75 31.75 38.1 38.1

7.1 8.7 10.3 10.3 11.1 12.7 14.3 17.5 20.6

5.0 6.1 7.5 6.1 7.0 8.2 9.1 11.2 15.2

6.4 8.0 9.6 8.2 9.3 10.9 12.2 15.0 20.3

5.30 6.90 8.40 9.90 11.50 13.10 14.65 17.86 17.86

11

BS CYCLE

BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

3/16” 1/4” 5/16” 3/8” 7/16” 1/2” 9/16” 9/16”

32 26 26 26 26 26 20 26

60.3 63.5 69.9 74.6 76.2 76.2 76.2 76.2

22.2 25.4 28.6 31.8 31.8 31.8 31.8 31.8

6.4 7.1 8.7 10.3 10.3 11.1 12.7 12.7

3.8 5.0 6.1 7.5 6.1 7.0 8.2 8.2

4.8 6.4 8.0 9.6 8.2 9.3 10.9 10.9

4.10 5.60 7.10 8.70 10.30 11.90 13.30 13.50

ME

BS 949 : 1951

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/8” 5/32” 3/16” 7/32” 1/4” 9/32” 5/16” 3/8”

40 40 40 40 40 32 32 32

49.2 54.0 60.3 60.3 63.5 63.5 69.9 74.6

15.9 19.1 22.2 22.2 25.4 25.4 28.6 31.8

4.8 6.4 6.4 6.4 7.1 7.9 8.7 10.3

2.7 3.1 3.8 4.4 5.0 5.6 6.1 7.5

3.3 4.0 4.8 5.6 6.4 7.2 8.0 9.6

2.55 3.25 4.10 4.90 5.80 6.10 7.10 8.60

BS CONDUIT BS 949 : 1951

12

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/2” 5/8” 3/4” 1” 1.1/4”

18 18 16 16 16

76.2 76.2 82.6 82.6 101.6

31.8 31.8 38.1 38.1 38.1

11.1 14.3 17.5 20.6 25.4

7.0 9.1 11.2 15.2 19.5

9.3 12.2 15.0 20.3 25.9

11.10 14.00 17.50 23.50 30.00

(U) NS

ANSI 94.9 : 1971

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

8 10 12 14 14 5/32” 5/32” 3/16” 3/16” 5/16” 11/16” 11/16” 1”

40 30 32 20 24 32 36 24 32 32 11 16 14

54.0 60.3 60.3 63.5 63.5 54.0 54.0 60.3 60.3 69.1 102.4 102.4 130.2

19.1 22.2 23.8 25.4 25.4 19.1 19.1 22.2 22.2 28.6 46.0 46.0 63.5

6.4 6.4 7.1 7.9 7.9 6.4 6.4 6.4 6.4 9.5 15.9 15.9 20.6

3.3 3.9 4.2 4.9 4.9 3.3 3.3 3.9 3.9 6.0 10.3 10.3 15.2

4.3 4.9 5.6 6.5 6.5 4.3 4.3 4.9 4.9 8.1 13.8 13.8 20.3

3.60 4.00 4.70 5.60 7.70 3.60 3.65 4.25 4.40 7.50 16.40 16.70 24.60

WHITWORTH FINE PITCH BS 949 : 1951

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/4” 5/16” 3/8”

32 40 40

63.5 69.9 74.6

25.4 28.6 31.8

7.1 8.7 10.3

5.0 6.1 7.5

6.4 8.0 9.6

5.60 7.30 8.90

13

BSPF

BS 949 : 1951

Carbon Steel Cut Thread Hand Taps

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/8” 1/4” 3/8” 1/2” 5/8” 3/4” 7/8” 1" 1.1/4” 1.1/2” 1.3/4” 2"

28 19 19 14 14 14 14 11 11 11 11 11

54.0 61.9 65.1 79.4 81.0 82.6 88.9 88.9 101.6 108.0 111.1 114.3

19.1 27.0 27.0 34.9 34.9 34.9 39.7 44.5 44.5 44.5 44.5 44.5

7.9 11.1 12.7 15.9 17.5 17.5 19.1 20.6 23.8 25.4 27.0 28.6

6.0 8.2 10.3 13.1 15.2 17.2 20.6 21.4 25.0 28.6 30.9 35.7

8.1 10.9 13.8 17.4 20.3 23.0 27.8 28.6 33.3 38.1 41.3 47.6

8.80 11.80 15.25 19.00 21.00 24.50 28.25 30.75 39.50 45.00 51.00 57.00

NPS

ANSI 94.9 : 1971

14

Nominal Diameter D

T. P. I. mm

L mm

I mm

I1 mm

a mm

d mm

Tapping drill sizes (mm)

1/8” 1/4” 3/8” 1/2” 3/4” 1”

27 18 18 14 14 11.1/2

54.0 61.9 65.1 79.4 82.6 95.3

19.1 27.0 27.0 34.9 34.9 44.5

7.9 11.1 12.7 15.9 17.5 20.6

6.0 8.2 10.3 13.1 17.2 21.4

8.1 10.9 13.8 17.4 23.0 28.6

9.10 11.90 15.25 19.00 27.00 30.50

Carbon Steel & High Speed Steel Circular Split Dies High Speed Steel Ground Dies Carbon Steel & High Speed Steel Die Nuts (Hexagonal Dies) Case Sets Tap Wrench & Die Stocks

15

BS 1127 : 1974

Carbon Steel & High Speed Steel Circular Split Dies

16

OD

THICKNESS

METRIC

Inch

Inch

13/16 "

1/4 “

mm 1.6 X 0.35 2.0 X 0.40 2.2 X 0.45 2.3 X 0.40 2.5 X 0.45 2.6 X 0.45 3.0 X 0.50 3.0 X 0.35, 0.60 3.5 X 0.60 4.0 X 0.35 , 0.50 4.0 X 0.70 4.0 X 0.75 4.5 X 0.50, 0.75 5 X 0.50, 0.75 5.0 X 0.80 5.0 X 0.90 5.5 X 0.50, 0.90 5.5 X 0.75 6.0 X 0.50, 0.75 6.0 X 1.00 7.0 X 0.75, 1.00

OD

THICKNESS

METRIC

Inch

Inch

1"

3/8”

mm 6.0 X 0.50, 0.75 6.0 x 1.00 7.0 X 0.75, 1.00 8.0 X 0.75, 1.00 8.0 X 1.25 9.0 X 0.75, 1.00 9.0 X 1.25 10 X 0.50, 0.75, 1.00 10 X 1.25 10 X 1.50

OD

THICKNESS

Inch

Inch

1.1/2 "

1/2”

BSW BSF Inch 1/16" 3/32" 1/8" 5/32" 3/16" 7/32" 1/4" -

UNC NS UNF No. / Inch No. / Inch 4 5 6 6 5/32" 8 8 11/64 " 10 & 3/16" 3/16" 12 12 & 7/32" 15/64" 1/4" 1/4" -

BSW BSF Inch 1/4" 9/32" 5/16" 3/8"

UNC UNF Inch 1/4" 5/16" 3/8"

NS

METRIC

BSW BSF

UNC UNF

NS

mm 11 X 1.00, 1.50 12 x ,1.00, 1.25 12 x 1.50 12 x 1.75 14 x 1.00, 1.25 14 x 1.50 14 x 2.00 15 x 1.50 16 x 1.00, 1.50 16 x 2.00 18 x 1.50 18 x 2.50 20 x 1.50, 2.50 20 x 1.50, 2.50

Inch 7/16 " 1/2 " 9/16 " 5/8 " 3/4 " -

Inch 7/16 " 1/2 " 9/16 " 5/8 " 3/4 " -

Inch 7/16 " 9/16 " 5/8 " 3/4 " -

Inch -

BSB BSCY Inch 3/16" 1/4" BSB BSCY Inch 1/4 9/32" 5/16" 3/8" BSB BSCY BSCON Inch 7/16 " 1/2 " 9/16 " 5/8 " 3/4 " -

ME

WF

BA

Inch 1/8" 5/32" 3/16" 7/32" 1/4" -

Inch 11/64 " 3/16 " 13/64 " 15/64 " 1/4 " -

No. 12 11 10 9 8 7 6 5 4 3 2 1 0 -

ME

WF

BSP

Inch 1/4" 9/32" 5/16" 3/8"

Inch 1/4" 9/32" 5/16" 3/8"

Inch 1/8 "

Pg

WF

BSP

No 7 X 20 9 x 18 11 x 18 13.5 x 18 13.5 x 18

Inch 7/16 " 1/2 " -

Inch 1/8" 1/4" 3/8" 1/2" 1/2”

BS 1127 : 1974

Carbon Steel & High Speed Steel Circular Split Dies

OD

THICKNESS

METRIC

BSW BSF

UNC UNF

NS

Inch

Inch

2"

5/8''

mm 20 x 1.50, 2.50 22 X 1.50 22 X 2.50 24 X 1.00, 1.50 24 X 3.00 25 x 1.50 26 x 1.50 27 x 1.50, 3.00 28 x 1.50 30 x 1.50, 3.50 25 x 1.50 26 x 1.50 27 x 1.50, 3.00 28 x 1.50 30 x 1.50, 3.50

Inch 1/2 " 9/16 " 5/8 " 3/4 " 7/8 " 1" -

Inch 1/2 " 9/16 " 5/8 " 3/4 " 7/8 " 1" -

Inch 9/16 " 5/8 " 3/4 " 7/8 " 1" -

OD Inch

THICKNESS Inch

2.1/4"

11/16''

2.1/2"

3"

4"

METRIC BSW/BSF UNC/UNF mm Inch Inch 27 x 3.00 30 x 3.50 1.1/8“ 1.1/8“ 32 x 1.50 1.1/4 “ 1.1/4“ 33 x 1.50, 3.50 -

BSB BSCY BSCON Inch 1/2 " 9/16 " 5/8 " 3/4 " 7/8 " 1" -

Pg

WF

BSP

No 16 x 18 21 x 16 21 x 16 -

Inch 1/2 " -

No. 1/4" 3/8" 1/2 " 5/8 " 3/4 " 7/8 " 1" 7/8 " 1" -

BSP Inch 7/8“ -

7/8''

34 x 1.50 35 x 1.50 36 x 1.50, 4.00 40 x 1.50

1.3/8 “ 1.1/2 “ -

1.3/8“ 1.1/2“ -

1.1/8“ 1.1/4“ -

7/8''

34 x 1.50 35 x 1.50 36 x 1.50, 4.00 38 x 1.50 39 x 4.00 42 x 4.50 45 x 1.50

1.1/2 “ -

1.1/2“ -

1.1/4“ -

1''

45 x 1.50 46 x 1.50 48 x 1.50, 5.00 50 x 1.50 52 x 1.50 55 x 1.50 60 x 1.50

1.3/4“ 2“ -

1.3/4“ 2“ -

1.3/8“ 1.1/2“ 1.3/4“ 2“ -

OD Inch 1" &1.1/2" 1.1/2" 1.1/2" & 2" 2" 2" & 2.1/2" 2.1/2" & 3" 3" 4" 4"

THICKNESS mm 10mm 14mm / 15mm 14mm / 15mm 19mm 20mm 25mm 25mm 25mm 27mm

BSPT / NPT Inch 1/8" 1/4" 3/8" 1/2" 3/4" 1" 1.1/4" 1.1/2" 2"

17

DIN 223

High Speed Steel Ground Dies

18

O.D. x THICKNESS in mm 16 x 5 16 x 5 16 x 5 20 x 5 20 x 5 20 x 5 20 x 5 20 x 5 20 x 7 20 x 7 20 x 7 20 x 7 20 x 7 25 x 9 25 x 9 25 x 9 25 x 9 30 x 11 30 x 11 30 x 11 38 x 10 38 x 10 38 x 10 38 x 10 38 x 10 38 x 10 38 x 14 38 x 14 45 x 14 45 x 14 45 x 14 45 x 14 45 x 14 45 x 18 45 x 18 45 x 18 55 x 16 55 x 16 55 x 22

SIZE in mm 1.6x0.45 2.5x0.45 2.6x0.45 3.0 x 0.50 3.5x0.60 4.0 x 0.70 4.5x0.75 5.0 x 0.80 6.0 x 0.50 6.0 x 0.75 6.0 x 1.00 7.0 x 0.75 7.0 x 1.00 8.00 x 0.75 8.00 x 1.00 8.00 x 1.25 10 x 1.00 10 x 1.25 10 x 1.50 12 x 1.00 12 x 1.25 12 x 1.50 14 x 1.00 14 x 1.25 14 x 1.50 12 x 1.75 14 x 2.00 16 x 1.00 16 x 1.50 20 x 1.00 20 x 1.50 20 x 2.00 16 x 2.00 18 x 2.50 20 x 2.50 22 x 1.50 24 x 1.50 24 x 3.00

BSW/BSF No./Inch 5/32” 3/16 “ 1/4 “ 5/16 “ 3/8 “ 7/16 “

UNC/UNF No./Inch 4 5 6 8 10 12 1/4 “ 5/16 “ 3/8 “ 7/16 “

1/2 “ 9/16 “ 5/8” 3/4” -

1/2 “ 9/16 “ 5/8” 3/4” -

BA No. 6 4 2 -

BSP Inch 1/8 “ 1/4 “ 3/8” 1/2” -

BS 1127:1974

Carbon Steel & High Speed Steel Die Nuts

A/F

METRIC

BSW/BSF

UNC/UNF

BSP

Inch

in mm

Inch

Inch

Inch

0.710 “

3 to 6

1/8 “ to 1/4”

1/4”

-

0.820 “

7 to 8

5/16 “

5/16 “

-

0.920 “

9 to 10

3/8 “

3/8 “

1/8 “

1.010 “

11

7/16 “

7/16 “

-

1.100 “

12 to 13

1/2 “

1/2 “

1/4 “

1.300 “

14 to 16

9/16 “ & 5/8 “

9/16 “ & 5/8 “

3/8 “

1.480 “

18 to 20

11/16 “ & 3/4 “

3/4 “

-

1.670 “

21 to 22

7/8 “

7/8 “

1/2”& 5/8”

2.050 “

24 to 26

1“

1“

3/4 “

2.220 “

27 to 32

1.1/8 “ & 1.1/4 “

1.1/8 “ & 1.1/4 “

7/8 “

2.580 “

33 to 35

1.3/8 “

1.3/8 “

1“

2.760 “

36 to 40

1.1/2 “

1.1/2 “

1.1/4 “

3.150 “

42 to 48

1.3/4 “

1.3/4 “

1.1/2 “

3.550 “

50 to 52

2“

2“

1.3/4 “

3.890 “

55 to 56

2.1/4 “

2.1/4 “

2“

19

ACCESSORIES

Tap and Die Case Sets

20

Ref. NO: METRIC 1 Taps (Second) Dies Accessories

No. of Pieces : 20 M6, M8, M10, M12, M14, M16, M20 1’’ OD - M6 to M10 & 1.1/2’’ OD - M12 to M20 Tap Wrenches - 2nos. & Die Stock - 2nos.

Ref. NO: METRIC 2 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 28 M6, M8, M10, M12, M14, M16, M20 1’’ OD - M6 to M10 & 1.1/2’’ OD - M12 to M20 Tap Wrenches - 2nos. & Die Stock - 2nos.

Ref. No: C 119 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 37 M6, M7,M8, M9, M10, M11, M12, M14, M16, M20 1’’ OD - M6 to M10 & 1.1/2’’ OD - M11 to M20 Tap Wrenches - 2no. & Die Stock - 2nos.

Ref. No: METRIC 3 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 21 M3, M4, M5, M6, M8, M10 13/16’’ OD - M3 to M5 & 1’’ OD - M6 to M10 Tap Wrenches - 1no. & Die Stock - 2nos.

Ref. No: METRIC 4P Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 17 M2, M3, M4, M5, M6, 13/16’’ OD - M2 to M6 Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: METRIC 4S Taps (Taper, Second, Bottom) Dies Accessories

No. of Pieces : 22 M2, M3, M4, M5, M6, 13/16’’ OD - M2 to M6 Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: METRIC 5F Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 35 MF6, MF8, MF10, MF12, MF14, MF16, MF18, MF20, M22, M24 1’’ OD - MF6 to MF10 + 1.1/2’’ OD - MF12 to MF20 + 2’’ OD - MF22 to MF24 Tap Wrenches - 2nos. & Die Stock - 3nos.

Ref. No: C 120 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 35 M6, M7,M8, M9, M10, M11, M12, M14, M16, M20, M22, M24 1’’ OD - M6 to M10 + 1.1/2’’ OD - M11 to M16 + 2’’ OD - M18 to M24 Tap Wrenches - 2nos. & Die Stock - 3nos.

Ref. No: METRIC 5C Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 35 M6, M8, M10, M12, M14, M16, M18, M20, M22, M24 1’’ OD - M6 to M10 + 1.1/2’’ OD - M12 to M20 + 2’’ OD - M22 to M24 Tap Wrenches - 2nos. & Die Stock - 3nos.

Ref. No: METRIC 6P Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 24 M3, M4, M5, M6, M8, M10, M12 1’’ OD - M3 to M12 Tap Wrenches - 2nos. & Die Stock - 1no.

Ref. No: METRIC 6S Taps (Taper, Second, Bottom) Dies Accessories

No. of Pieces : 31 M3, M4, M5, M6, M8, M10, M12 1’’ OD - M3 to M12 Tap Wrenches - 2nos. & Die Stock - 1no.

ACCESSORIES

Tap and Die Case Sets

Ref. No: C 114 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 36 M2, M3, M4, M5, M6, M7,M8, M9, M10, M11, M12 13/16’’ OD - M2 to M6 + 1’’ OD - M7 to M12 Tap Wrenches - 1no. & Die Stock - 2nos.

Ref. No: METRIC 7 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 18 M6, M8, M10, M11, M12 1’’ OD - M6 to M10 + 1.1/2’’ OD - M11, M12 Tap Wrenches - 1no. & Die Stock - 2nos.

Ref. No: C 118 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 23 M6, M7,M8, M9, M10, M11, M12 1’’ OD - M6 to M12 Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: METRIC 8 Taps (Taper & Bottom) Dies Accessories

No. of Pieces : 23 M3, M4, M5, M6, M8, M10, M12 1’’ OD - M3 to M12 Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: C 37 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 24 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’, 5/8’’, 3/4’’ 1’’ OD - 1/4’’, 5/16’’, 3/8’’ + 1.1/2’’ OD - 7/16’’, 1/2’’, 5/8’’, 3/4’’ Tap Wrenches - 1no. & Die Stock - 2nos.

Ref. No: INCH 9 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 28 1/4’’, 5/16’’, 3/8’’, 1/2’’, 9/16’’, 5/8’’, 11/16’’, 3/4’’ 1’’ OD - 1/4’’, 5/16’’, 3/8’’ + 1.1/2’’ OD - 9/16’’, 5/8’’, 11/16’’, 3/4’’ Tap Wrenches - 2no. & Die Stock - 2nos.

Ref. No: C 31 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 24 1/8’’, 3/16’’, 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’ 13/16’’ OD - 1/8’’, 3/16’’ + 1’’ OD - 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’ Tap Wrenches - 1no. & Die Stock - 2nos.

Ref. No: C 82 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 17 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’ 1’’ OD - 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’ Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: C 52 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 20 3/16’’, 5/16’’, 1/4’’, 3/8’’, 7/16’’, 1/2’’ 1’’ OD - 3/16’’, 5/16’’, 1/4’’, 3/8’’, 7/16’’, 1/2’’ Tap Wrenches - 1no. & Die Stock - 1no.

Ref. No: C 85 Taps (Taper & Bottom) Dies Accessories *BSW/BSF/UNC/UNF

No. of Pieces : 32 1/4’’, 5/16’’, 3/8’’, 7/16’’, 1/2’’, 5/8’’, 3/4’’, 7/8’’, 1’’ 1’’ OD - 1/4’’, 5/16’’, 3/8’’ + 1.1/2’’ OD - 7/16’’, 1/2’’, 5/8’’ + 2’’ OD - 3/4’’, 7/8’’, 1’’ Tap Wrenches - 2nos. & Die Stock - 3nos.

21

ACCESSORIES

Tap Wrench and Die Stocks

TAP CAPACITY Inch 1/16”-1/4” 1/8”-1/2” 5/32”-3/8” 3/16”-1/2” 3/16”- 5/8”

ADJUSTABLE TAP WRENCHES (ZINC DIE CAST BODY) TAP CAPACITY OVERALL NOMINAL LENGTH mm Inch 2 - 6 MM 7” 4 - 10 MM 9” 4 - 10 MM 9” 5 - 12 MM 11-3/16” 5 - 12 MM 11-3/16”

OVERALL NOMINAL LENGTH mm 180 230 230 285 285

TAP CAPACITY Inch 1/16"-1/4" 1/8"-1/2" 5/32"-3/8" 3/16"-1/2" 3/16"- 5/8" 1/4" - 3/4" 5/16" - 1" 3/8" - 1"

ADJUSTABLE TAP WRENCHES (FORGED STEEL) TAP CAPACITY OVERALL NOMINAL LENGTH mm Inch 2-6 MM 6 - 1/4'' 4-10 MM 8 4-10 MM 8 5-16 MM 10 - 1/4'' 5-16 MM 10 - 1/4'' 6-20 MM 13 - 1/4'' 8-25 MM 18 - 1/4'' 8-25 MM 18 - 1/4''

OVERALL NOMINAL LENGTH mm 170 200 200 260 260 343 465 465

TAP CAPACITY Inch 1/16"-5/32" 5/32" - 1/4" 3/16" - 5/16" 1/4" - 1/2"

TAP CAPACITY mm 2 - 4 MM 4 - 6 MM 5 - 8 MM 6 - 12 MM

T HANDLE TAP WRENCHES OVERALL NOMINAL LENGTH Inch 2-3/8" 2-11/16" 3 - 5/32" 3 - 1/2"

OVERALL NOMINAL LENGTH mm 60 MM 69 MM 80 MM 88 MM

TAP CAPACITY Inch 5/32" - 1/4" 1/4" - 1/2"

T HANDLE TAP WRENCHES RACHET TYPE TAP CAPACITY OVERALL NOMINAL LENGTH mm Inch 4 - 6 MM 2-11/16" 6 - 12 MM 3 - 1/2"

OVERALL NOMINAL LENGTH mm 69 MM 88 MM

DIE STOCKS

22

CAPACITY O/D THREADING DIES Inch mm 5/8” 15 13/16” 20 1” 25 1-5/16” 33 1-1/2” 38 2” 50 2-1/4” 57 2-1/2” 63 3” 75 4” 100

OVERALL NOMINAL LENGTH Inch 5-1/2” 6-3/4” 8-3/4” 10” 12-1/2” 15-9/16” 16-1/2” 19” 22-1/2” 35”

*Tap Wrench and Die Stocks are supplied in export markets only.

OVERALL NOMINAL LENGTH mm 140 MM 170 MM 222 MM 254 MM 317 MM 395 MM 420 MM 480 MM 572 MM 890 MM

Tap and Die Terminology Lead / Chamfer: The taper at the thread end of the tap or

the throat of the die, made by cutting away the crests of the first few threads is to distribute the work of cutting, over several threads and act as guide in starting the tap or die. The chamfer is relieved to facilitate cutting. The tap is classed as Taper, Second or Bottoming according to the length of chamfer which approximate to the following :

For Taps

1. Taper Tap……....…4° per side (10 to 12 threads)

2. Second Tap….....…8° per side (6 to 8 threads)

3. Bottoming Tap…...22° per side (1.1/2 to 2.1/2 threads)

For Dies

1. Stamped side………45°

2. Back side……………60°

Clearance Hole: The holes in the die that provide the cutting rake and chip clearance. Effective Diameter: The pitch circle diameter of thread as generated by the straight line parallel to axis of the tap.

This straight line is called as pitch line. Along the pitch line the width of the thread and width of spaces are equal on a perfect thread. Flute: The grooves in the tap that provide the cutting rake and chip clearance. Helix angle: The angle made by helix of a thread at the pitch diameter with a plane perpendicular to the axis. The

helix angle increases continuously from the crest to the root of the thread. Land, Land width: It is the face between the cutting edge and the non cutting edge. Web: The central portion of the tap which s the land and extending along flute portion of the tap. Lead / Pitch: The distance a screw thread advanced axially in one complete turn. On a single thread the lead and

the pitch are identical. Major Diameter: The largest diameter on a parallel screw thread or tap. The term “Major Diameter” is a replacement

for the term “Outside Diameter” as applied to the thread of a screw and also the term “Full Diameter” as applied to the thread of a nut. Minor Diameter: The smallest diameter on a parallel screw thread or tap. The term “Minor Diameter” is a replacement

for the term “Core Diameter” and “Root Diameter” as applied to the thread of a screw and also the term “Inside Diameter” as applied to the thread of a nut. Number of Threads / TPI: The number of threads in a length of one inch.

23

Applications of Taps & Dies Automobile Industry Cylinder liner and Cylinder head manufacturers General purpose applications in small workshops, garages, tool rooms and maintenance departments Motor cycle body frames: Spatter cleaning and removing paint from threaded portion. Carburetor and speedometer manufacturers High Speed Steel Dies are used in removing paint from threaded portion in rear axles of cars, trucks, buses, etc. Dies are used by gas valve manufacturers.

Engineering Industry Air Compressors / Blower manufacturers Cooling towers and heat exchangers Brass component manufacturers Pipe and Pipe fitting manufacturers. Sheet Metal Industry Thread dressing of diesel engine components Steel furniture manufacturers Steel window manufacturers Bus and Truck body building workshops Textile industry Electrical industry

Household appliance manufacturers Pressure cookers Fans, Air coolers, Air conditioners Flour mills, Mixers and Grinders

24

Totem Range Of Products HIGH SPEED STEEL GROUND THREAD TAPS.

Range: 1.6mm – 120mm, 1/16’’ – 3’’ . Higher dimensions can be manufactured as per order.

Surface Treatment: TiN/TiCN/TiAIN/Steam Tempered

Material: HSS – M2 Steel and HSSE M 35 / M 42 Steel

Thread Forms: BSW/BSF/UNF/UNC/MM/BA/BSP/BSPT/BSCY/WF/ ME/BSCON/NPT/NGT/ACME.

Variety: Hand Taps, Machine Taps – Straight Flute, Spiral Flute, Spiral Point, Fluteless

SOLID CARBIDE END MILLS (SQUARE AND BALL NOSE)

Material: Ultrafine grade 12% Cobalt Carbide and micro grain 10% Cobalt Carbide.

Size Range: 1mm to 32mm (and equivalent sizes in inches)

Surface Treatment: TiN/TiCN/TiAIN/Steam Tempered

Variety: Available in 2, 3 and 4 Flute geometries

SOLID CARBIDE DRILLS

Jobber Drills available in size range 1mm to 20mm Ideal for Cast Iron, Aluminium, Bronze and Magnesium alloys. Hi – Tuff Drills available in size range 1mm to 20mm Ideal for Stainless Steel, Tool Steel, Titanium and Nickel based alloys.

Through Coolant Drills available in size range 4mm to 20mm

Ideal for deep hole drilling on medium / low Carbon steel,

Cast Iron, Stainless Steel and Aluminium.

TUNGSTEN CARBIDE ROTARY BURRS

Size Range: 1.5mm to 25mm Head Diameter and Shank Diameter 3mm, 6mm, 8mm, 1/8”, 1/4”.

Type of cuts: Single Cut, Double Cut, Diamond Cut, Aluma Cut and Chip breaker

25

and Conditions

Prices: Prices are subjct to revision. For local sales price please your nearest local sales office. For export sales price please at : [email protected] Payment: In case of local sales goods will be sold as per the standard price list and agreed and conditions. In case of export sales the preferred mode of payment will be in advance or against irrevocable and confirmed documentary credit to be opened in our favour with an Indian bank. All banking commission and charges have to be borne by the customer. Right of ownership: We reserve the right of ownership of all goods supplied until the sale price, plus all incidental charges have been fully cleared. Despatch: Deliveries take place at the purchaser’s risk. Delivery: Confirmed delivery dates are non-binding. We will take due care to maintain these dates. However we cannot accept responsibility of direct or consequential losses due to delayed deliveries. Special orders: For all special tools we reserve the right to over or under supply the ordered quantity by up to 10%. Guarantee: Tools recognised to be defective by the company will be replaced free of charge but without prejudice. DAMAGE,SHORTAGE OR LOSS: The Seller shall not be under liability in respect of damage, shortage or loss of the goods in respect of which the Seller has not be notified in writing within 3 days after receipt of the goods by the Buyer. Drawings and sketches: The reproduction of transmission of drawings and other documents to a third party are prohibited. The information (drawings and prints) in our catalogue is for guidance only and is not binding. Special conditions: In the case of partial or total disruption of our production: we reserve the right to partially or totally cancel our delivery commitments. The range shown in the catalogue is for reference purpose only and we do not essentially stock all the items. Please respective marketing department for delivery and price. Tribunal: All disputes are subject to Indian Law. All cases will subject to fall within the jurisdiction of Mumbai.

26

Warning: Any cutting tool may break or shatter if improperly used. We recommend use of safety accessories like glasses, gloves, etc. at all times in the vicinity of use. Grinding of taps or dies may produce hazardous dust and should only be done under established safety guidelines.

EXPORTING TO : North America: USA, Mexico, West Indies, Canada

Middle East: Turkey, Lebanon, Kuwait, UAE, Saudi Arabia, Iran

South America: Chile, Columbia, Uruguay

West Asia: Pakistan, Sri Lanka, Bangladesh

Europe: UK, , Poland, Russia

South East Asia: Thailand, Vietnam, Malaysia, Indonesia

Africa: Egypt, Kenya, Tanzania, South Africa

Far East : Australia and New Zealand

For Export enquiries write to us on: [email protected] or Fax at 91-22-28473191.

SALES OFFICES IN INDIA Ahmedabad 1st Floor, Pran Vijay, Near Times Of India, Ashram Road-Pin 380009. Tel: 079-26587769 Fax: 079-26584618 E.mail : [email protected] Kolkata

222, AJC Bose Road, Circular Centre, Flat 1&2, 1st Floor, Pin – 700 017 Tel: 033-2267 3076 Fax: 033-2289 1311

Mumbai

* INDORE

Saki Powai Road, Chandivali, Pin – 400 072 Tel: 022-2847 1861 Fax: 022-2847 1799 E.mail : [email protected]

204, N28, Anoop Nagar, Indore (M.P.) Pin-452 008. Tel: 09826906346 E.mail : [email protected]

New Delhi

Tel: 09838004355 E.mail : [email protected]

9/10-3, Asaf Ali Road, Pin – 110 002 Tel: 011-4300 0120/9 Fax 011-4300 0130 E.mail : [email protected]

* Ludhiana

Pune

* Kanpur

237, Jagjit Nagar, Threeka Road, Near Rajguru Nagar, Pin-142 021. Tel: 09815165982 E.mail : [email protected]

1/12, Annapurna, Karve Road, Opp. S. N. D. T. College, Erandawane, Pin – 411 004. Tel: 020-2546 6442 Fax: 020-2546 6286 E.mail : [email protected]

* Rajkot

* BARODA

* Secunderabad

12/190, MIG Flats, Karelibaug, Baroda, Pin-390 018. Tel: 09825917524 E.mail : [email protected]

5th Floor, P.V.S. Mansion, Somasundaram Street, Beside Manju Theatre, Sarojinidevi Road, Pin-500 003. Tel: 040-2781 4585 Fax: 040-2784 4967 Mobile : 09885260611 E.mail : [email protected]

* Chandigarh

186, Puskardham Society “Nimal” Nr. Alap Avenue, University Road, Pin – 360005 Tel: 09924127754 E.mail : [email protected]

House No. 527, Sector 11B, Pin-160011. Tel: 09417028106 E.mail : [email protected] * Residential Representatives

For all domestic inquiries write to us on [email protected] or fax at 91-22-28473191.

Designed & Printed by : Spenta Multimedia: 91-22-24811010

FORBES PRECISION TOOLS

Saki Powai Road, Chandivali, Mumbai – 400 072. Tel: 91-22-28471861, 28471298 Fax : 91-22-2847 1799 / 2847 3191 A-7/1, MIDC Area, Chikalthana, Aurangabad-431210 Tel: 91-240-2485226 Fax: 91-240-2485058

www.totem-forbes.com