Types Of Agitators, Agitator's Design And Significance - Pharma Engineering 252p

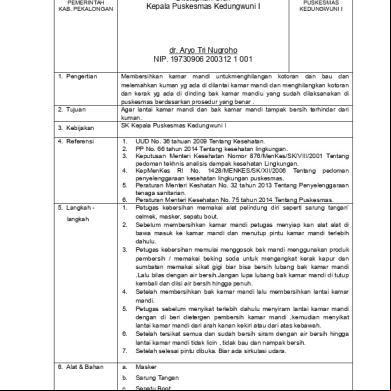

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3i3n4

Overview 26281t

& View Types Of Agitators, Agitator's Design And Significance - Pharma Engineering as PDF for free.

More details 6y5l6z

- Words: 3,058

- Pages: 23

Calculations

Me

Documentation

Equipment Design

Forum

How To

Softwares

Write For Us

About Me

Pharma Engineering an engineer's choice

Home agitator design Types of Agitators, Agitator's Design and Significance

Types of Agitators, Agitator's Design and Signi cance Ajay Kumar Kalva year ago agitator, design

PO PULAR PO STS

RECENT PO ST

Types of Agitators, Agitator's Design and Significance

[How To] Select a Motor Capacity for Agitator

Tonne of Refrigeration, How to Calculate required TR

[How to] find Reactor Heat Transfer Area Theoretically

[HOW TO]Calculate the Volume Occupied by Torispherical Dish

Search this site...

Search

Our Newsletter Get All The Latest Updates Delivered Straight Into Your Inbox For Free!

ENTER YOUR EMAIL ADDRESS...

Save The Children

Hello readers.....!! Today i gonna give you a description that limits upto my knowledge, and most of you may find it useful, about the Industrial Agitators, Types of Agitators, their Power Numbers, Design Equations and their significance in production.

Introducing or discovering the types of agitators in pharma field is certainly a revolution because different agitators will have different purposes and different advantages, but most commonly used agitators are Anchor, Propeller, Turbine, Paddle etc., and still these agitators are sub divided into types, for example Round Anchor and Anchor combined with Gate are two types of Anchor.

So, for knowing the types of agitators and their significance you don't need any basic knowledge, but just an idea that

"what is an agitator ?, And what it can do ??" "What is the difference between Agitation and Mixing ??" Agitator : An agitator is something which is used to stir liquid or mixture of liquids.

Also Read:

How to Select a Condenser? What Does a TR exactly means? How to Calculate the Energy of Steam?

What it can do ?? : It can be used in various operations, in a pharma industry it can be used in multiple operations like reactions, work up's, drying, filtration, etc.,

We Care For Children, Do U .....!!! Rs. 500/- Can Make a Difference......!!! Sharing is Caring ❤, Trust Me.........!!!!

Blog Archive ► 2017 (3) ▼ 2016 (33) ► December (1) ► November (1) ► October (3) ► September (1) ► June (5) ▼ May (10) Overall Heat Transfer Co-efficient Calulation base... Outlines for Deg a Chiller Plant Pressure and its Altitude Dependence Pumps in Series Vs Pumps in Parallel Overall Heat Transfer Co-Efficient Calculation

Difference between Agitation and Mixing :

Agitation Scale up [How To] Select a Condenser Tonne of Refrigeration, How to Calculate required ... Types of Agitators, Agitator's Design and Signific... [How To] Select a Motor Capacity for Agitator ► April (6) ► March (5) ► February (1) ► 2015 (5)

Like Us On Facebook

Agitation is the process of keeping a mixture that has been mixed in the proper mixed state required for the 'end' product.

Mixing refers to the actual stirring of different liquids and/or materials to blend them together into an end product or mixture. Once this mixture is 'mixed' it may require agitation to keep the mixture in the proper 'mixed' state.

So, Now i'll go into our topic,

There are two types of Agitators commonly used,

1. Mechanical Agitators, 2. Electronically Controlled Agitators, I'll demonstrate commonly used Mechanical Agitators.

Page not found The server can't be found, because the DNS lookup failed. DNS is the network service that

Recommended For You:

How to Select Motor Capacity of an Agitator? How to do Scale Up calculations? How to Design an Industrial Column?

Paddle Agitators: This is one of the most primary types of agitators with blades that reach up to the tank walls. Paddle agitators are used where an uniform laminar flow of liquids is desired.

Anchor Agitators : This simple agitator consists of a shaft and an anchor type propeller and can be mounted centrally or at an angle. It is mainly used in reactors.

Radial Propeller Agitators : Radial agitators consist of propellers that are similar to marine propellers. They consist of two to four blades that move in a screw like motion, propelling the material to be agitated parallel to the shaft.

Propeller Agitators : A propeller agitator is shaped with blades tapering towards the shaft to minimize centrifugal force and produce maximum axial flow. Propeller agitators are popular for simple mixing jobs.

Send us a message

Turbine Agitators : Yet another type of process agitator is the turbine agitator. Turbine agitators can create a turbulent movement of the

fluids due to the combination of centrifugal and rotational motion.

Helical Agitators : These agitators have blades with a twisted mechanism, just like the threads of a screw. The curves result in a vigorous motion of the fluids to be agitated. Helical agitators are most useful for mixing viscous liquids.

A simplified brief description has been tabulated below.

Agitator Type

Applications

Advantages

Disadvantages

* Mixing of Solids,

Paddle

* Heavy duty,

* Slurry Mixing,

* Apt for Slow operation,

* Used during Crystals

* Can have 2 or 4 blades

* Power Consumption is very high,

* Inefficient Mixing

forming phase during Super saturated Cooling Turbine

*Straight Blade *Pitched Blade *Curved Blade

* Liquids and Gas reactions,

* Generates high Radial Flow,

* Highly used during

* Not preferred for solvents with high

Reaction and Extraction

* Highly used for

Operations.

dispersion operations

viscosity[NMT 20 ]

*Disk Blade * Have to use in addition Screw type

to other agitators.

* Mostly used in Food processing.

* Uniform mixing of High viscous masses.

* Not preferred for im-miscible solvents.

Helical Blade

*Ribbon

* Most Probably used in

* Can handle Visco

* Low possibility for Radial

Type

Paint industry.

-elastic liquids efficiently

mixing

*Helical Screw * Increase possible heat

Anchor

* Highly used in Pharma Industry for Several Operations

transfer rate in reactors, from reactor heat transfer surface to Mass.

Gate

* Highly used for blending Operations

* Required high Efficiency Gear box, * Required high Power.

* Provides efficient

* Not preferred

Mixing and agitation control,

when both liquids and gases

* Can handle Psuedo

combine

-plastic liquids.

involves * Need to be operated

* Suitable for GLR's, Propeller

ANFD's, can handle Corrosive materials with Glass lining.

* Will increase the

at high speed to

homogeneity,

avoid solid settlings in reactors.

* Can be used in two different patterns for

* Need to be

drying and pressing.

operated at low speeds in drying operations.

Diameter of Agitator: Usually the diameter of agitator depends on the Diameter of the vessel, It is generally 1/3rd the diameter of the tank for Marine Propeller, Axial flow turbine, Turbo Propeller, Disc Blade turbine, Flat Blade turbine, Backward Blade turbine.

It is generally 4/5th of the diameter of the tank for Paddle, Anchor, Gate.

Type of Agitators and their functions:

Marine Propeller is generally an item produced by casting process in a foundry and it has 3 or 4 blades. Cast agitators have two basic advantages, uniformity of material and hard surface. These have tapering blades, and angle of blade varies from root to tip. This produces maximum axial flow. The diameter of Marine Propeller impeller is 15% to 30% of diameter of tank. These have tip speeds between 300 to 500 meters per minute.

Axial Flow Turbine, Turbo Propeller and Flat Blade Turbine have blades ranging from 3 to 6. These have tip speeds between 200 to 300 meters per minute. The diameter of impeller is 25% to 60% of tank diameter. For Axial Flow Turbine and Turbo Propeller, the angle of blade varies from 30 degrees (for less viscous liquids) to 60 degrees (for more viscous liquids). Standard angle is 45 degrees. Power requirement increases with higher pitch angle. For Flat Blade Turbine, the length of blade is 25% of diameter, and disk diameter is 60% to 70% of the diameter of impeller.

Paddle, Anchor, or Gate have only 2 blades. These extend close to the tank wall and have tip speeds between 80 to 150 meters per minute. These push and rotate the liquid in a laminar flow. There is no axial or radial mixing. The width of blade is 1/8th or 1/10th of the agitator diameter.

Number of Agitators:

There can be many number of agitators connected to a shaft, and it can be calculated as

Number of agitators = (Maximum liquid height x specific gravity) / Diameter of tank.

Gap between two Agitators = Liquid height / (Number of impellers - 0.5). Basic Design Equations for a Vertical Vessel and Agitator:

Vessel Volume = (pi x vessel dia x vessel dia x vessel length) / 4.0 Agitator Shaft length = vessel length + (vessel dia x 0.25) For Rectangular Tanks, Tank Volume = Vessel Length x Vessel Breadth x Vessel Height

Agitator Shaft length = Vessel Height

Based on geometry of vessel, many factors for impeller can be decided. Agitator Speed Marine Propeller

Axial Flow Turbine

Turbo Propeller

100 - 300 RPM

100 - 300 RPM

100 - 300 RPM

Power Number

Pumping Factor

Impeller Diameter

* 0.3 for 3 bladed impeller,

* 0.33 for 3 bladed,

1/3rd of tank

* 0.33 for 4 bladed impeller

* 0.34 for 4 bladed.

dia

* 1.35 for 3 bladed,

* 0.6 for 3 bladed,

* 1.4 for 4 bladed,

* 0.69 for 4 bladed,

1/3rd of tank

* 1.45 for 5 bladed,

* 0.78 for 5 bladed,

dia

* 1.6 for 6 bladed.

* 0.87 for 6 bladed.

* 1.35 for 3 bladed,

* 0.6 for 3 bladed,

* 1.4 for 4 bladed,

* 0.69 for 4 bladed,

1/3rd of tank

* 1.45 for 5 bladed,

* 0.78 for 5 bladed,

dia

* 1.6 for 6 bladed.

* 0.87 for 6 bladed.

Disc Blade Turbine

100 - 300 RPM

5.0

0.7 - 0.8

Flat Blade Turbine

100 - 300 RPM

5.0

0.7 - 0.85

1/3rd of tank dia 1/3rd of tank

dia Backward Blade Turbine

100 - 300 RPM

5.0

0.65 - 0.85

Paddle

50 RPM

5.0

0.03

Anchor

50 RPM

5.0

0.07

Gate

50 RPM

5.0

1.0

1/3rd of tank dia 80% of tank dia 80% of tank dia 80% of tank dia

AGITATOR COMPARISON CHART:

Today, the major concerns of the chemical and pharmaceutical industries are improving performance and reducing production costs. Agitation, mixing and heat transfer are major factors in maximizing the efficiency of a process. The various blade designs in our agitator product range have undergone significant research and testing, making it possible to use a scientific approach to agitation and heat exchange techniques that will optimize your process. The chart below illustrates the different types of blades available and the characteristics of each.

That's it.........!! Cheers..... if you understand,

Excel Sheet has been simulated for design of Agitator and you can it here,

HERE Any Queries feel free to ask,

Comments are most appreciated.!

Note: Some of the Data Interpreted here is not of my own, but from a generous Genius "Satish Lele"

Related Articles:

How to calculate Reactor Heat Transfer Area ? How to calculate Distillation Time cycle ? How to select a Vaccum pump ? How to Calculate Volume occupied by Torispherical Dish ?

About The Author Hi! I am Ajay Kumar Kalva, Currently serving as the CEO of this site, a tech geek by ion, and a chemical process engineer by profession, i'm interested in writing articles regarding technology, hacking and pharma technology. Follow Me on Twitter AjaySpectator & Computer Innovations Facebook

Share This:

CHILLING

Twitter

AGITATOR

Google+

Pinterest

Linkedin

CALCULATIONS

Outlines for Deg a Chiller Plant

Types of Agitators, Agitator's Design and Signi cance

[How To] Design a Condenser

May 29, 2016

May 05, 2016

Apr 21, 2016

15 comments:

1.

UNKNOWN 1 JANUARY 2017 AT 17:37

which utility is suitable for condensing acetone vapours under vacuum and under atmposphere in condensor...chilled water 8 deg. centigrade or brine -10 degree centigrade.. Reply

Replies 1.

AJAY KUMAR 1 JANUARY 2017 AT 17:52

Hey Mr.Anonymous, if you are having two condensers, then go with chilled water for primary and chilled brine for secondary, and if you are able to maintain the vapour temperature above 15 deg C under vacuum, then go with -10 degC Brine or 5 degC chilled water, if the temperature below 15 degC then use chilled brine at -20 degC, and in case of the vacuum distillation, to have a equalisation line from secondary condenser to collection receiver, if the distillation is an atmospheric one, directly go with RT water at below 30 degC,

2.

ANSHU BHARGAVA 2 JANUARY 2017 AT 09:51

Can you explain theoretically and calculate and tell how to select utility as per the above post.pls. give ur mail id so that i can share the sketch..

3.

AJAY KUMAR 2 JANUARY 2017 AT 21:13

using a better utility for condenser will enhance the rate of distillation, for a chilled brine at -10 deg C, the temperature difference can be considered as 7-8 deg C, and for a utility like chilled water having a inlet temperature of 8 deg C, the temp difference will be around 3-4 degC, because the reaction mass temperature will be around 15-20 degC under vacuum, so mostly the vapours will reach equillibrium with utility outlet, and in the process of condensing the vapour will exchange only latent heat, whereas in case of -10 degC brine, there will be exchange of sensible heat also, and if you want to calculate it theoretically

then read the post in this link, then you will get a clear idea, http://pharmacalc.blogspot.com/2016/09/how-to-calculate-rate-of-distillation.html try to do a reverse calculation baon the fixed rate of distillation and find the LMTD of both cases, which uses brine at -10degC and chilled water at 8degC, then you will come to know the difference.

Reply

2.

ANONYMOUS 6 JANUARY 2017 AT 22:26

Hello sir, I am chemical engineering student I am doing my final year project on extraction of oil from slurry in oil refineries.can you suggest us some ideas Reply

3.

AJAY KUMAR 7 JANUARY 2017 AT 06:59

so i think, it is something like Lube oils refining, right?? Thats a good one, and i too tried that during my project but finally got diverted, Give your best good luck, and regarding extraction any possible help i'll do, mail me @ [email protected] Reply

4.

HIRENKUMAR KAYASTH 1 FEBRUARY 2017 AT 19:55

Please tell me how to do piping? How to design pipeline Header and Tappings from it? Reply

Replies 1.

AJAY KUMAR 1 FEBRUARY 2017 AT 20:41

A x V = A1 x V1 + A2 x V2 + A3 x V3 +...................... But, V = V1 = V2 = V3 = .............. [this is as per thumb], A = A1 + A2 + A3 +................ D^2 = D1 ^2 + D2 ^2 + D3 ^2 + .............. that's it, the number of tappings given should satisfy the above derived eqn.

Regards, PHARMA ENGINEERING

Reply

5.

ANONYMOUS 3 MAY 2017 AT 14:52

what is the major difference between impeller,propellerand agitator Reply

Replies 1.

AJAY KUMAR 4 MAY 2017 AT 20:38

Mostly there wont be anything like a Propeller, may be i've mentioned above that's just for understanding purpose, because Propeller is what you see in a table fan, and the agitator that was usually called as propeller in pharma industry is strictly called as Retreat curve agitator,

Coming to your question, Impeller is nothing but an agitator, and for example if an retreat curve is having two agitators then it is said to have 2 impellers. That's it.

Reply

6.

ANSHU BHARGAVA 5 MAY 2017 AT 13:01

How can we calculate power for propeller & anchor used in glass lined reactor.... Reply

Replies 1.

AJAY KUMAR 6 MAY 2017 AT 10:04

Let it be a 10KL GLR, and the dia be 2.5m, and RPM is 110, by thumb dia of propeller will be 1/3rd of reactor dia, For Propeller, D = 2.5/3 = 0.83m, N = 110 rpm, rho = 1000 Cu.m / Kg, Np = 1.5 P = 1.5 x 1000 x ( ( 110/60 ) ^ 3 ) x ( 0.83 ^ 5 ) = 3641 Watts = 3.64 KW, For Anchor. D = 2.5 x 0.8 = 2m, N = 48 rpm, Np = 5, P = 5 x 1000 x ( (48/60) ^ 3 ) x ( 2 ^ 5 ) = 81920 Watts = 81.9 KW. That's it..........!!!!

Reply

7.

ANUJ GANDHI 4 JULY 2017 AT 17:31

Hi, Great site, and great work. We are a 30 year old manufacturing firm specializing in chemical and pharmaceutical reactors. We are currently looking for professionals who can independently design agitators for the process and mechanical aspect. If you know any such individuals, please ask them to reach out to me at [email protected]. Cheers Anuj Reply

8.

ANSHU BHARGAVA 7 JULY 2017 AT 17:08

how can we design spray ball ..how to select number of holes and flow from holes in spray ball? Reply

Replies 1.

AJAY KUMAR 12 JULY 2017 AT 14:07

Hello, as like previously mentioned, A*V = ( A1 * V1 ) + ( A2 * V2 ) + ( A3 * V3 )+................, V = V1 = V2 = V3 = ............, So, A = A1 + A2 + A3 + ........, (D^2) = (D1 ^2) + (D2 ^2) + (D3 ^2) + ........, D is line size, D1, D2, D3,....... are nozzle sizes, for how many nozzles the equation satisfied, those many nozzles you need to consider for a spray ball. Regards, PHARMA ENGINEERING

Reply

Add comment

Enter your comment...

Comment as:

Publish

M Erwin Yamashita (Google)

Preview

Sign out

Notify me

Links to this post Create a Link

Newer Post

Older Post

OUR TEES

ABOUT

Hi! I am Ajay Kumar Kalva, Currently serving as the CEO of this site, a tech geek by ion, and a chemical process engineer by profession, i'm interested in writing articles regarding technology, hacking and pharma technology.

agitator

Calculations

chilling

design

Documentation

DQ

iq

network analysis

Power consumption reaction kinetics

Followers

Us by Promoting Us

Labels

softwares

Ikuti

Created By Sora Templates | Distributed By Ajay Kumar Kalva

FTA OQ

pressure calculation scaleups

how to

pumps

simulation

timecycle for heating/cooling

Tons of Refrigeration

Pengikut (0)

OOS

Condenser

utilities

vacuum pump

Me

Documentation

Equipment Design

Forum

How To

Softwares

Write For Us

About Me

Pharma Engineering an engineer's choice

Home agitator design Types of Agitators, Agitator's Design and Significance

Types of Agitators, Agitator's Design and Signi cance Ajay Kumar Kalva year ago agitator, design

PO PULAR PO STS

RECENT PO ST

Types of Agitators, Agitator's Design and Significance

[How To] Select a Motor Capacity for Agitator

Tonne of Refrigeration, How to Calculate required TR

[How to] find Reactor Heat Transfer Area Theoretically

[HOW TO]Calculate the Volume Occupied by Torispherical Dish

Search this site...

Search

Our Newsletter Get All The Latest Updates Delivered Straight Into Your Inbox For Free!

ENTER YOUR EMAIL ADDRESS...

Save The Children

Hello readers.....!! Today i gonna give you a description that limits upto my knowledge, and most of you may find it useful, about the Industrial Agitators, Types of Agitators, their Power Numbers, Design Equations and their significance in production.

Introducing or discovering the types of agitators in pharma field is certainly a revolution because different agitators will have different purposes and different advantages, but most commonly used agitators are Anchor, Propeller, Turbine, Paddle etc., and still these agitators are sub divided into types, for example Round Anchor and Anchor combined with Gate are two types of Anchor.

So, for knowing the types of agitators and their significance you don't need any basic knowledge, but just an idea that

"what is an agitator ?, And what it can do ??" "What is the difference between Agitation and Mixing ??" Agitator : An agitator is something which is used to stir liquid or mixture of liquids.

Also Read:

How to Select a Condenser? What Does a TR exactly means? How to Calculate the Energy of Steam?

What it can do ?? : It can be used in various operations, in a pharma industry it can be used in multiple operations like reactions, work up's, drying, filtration, etc.,

We Care For Children, Do U .....!!! Rs. 500/- Can Make a Difference......!!! Sharing is Caring ❤, Trust Me.........!!!!

Blog Archive ► 2017 (3) ▼ 2016 (33) ► December (1) ► November (1) ► October (3) ► September (1) ► June (5) ▼ May (10) Overall Heat Transfer Co-efficient Calulation base... Outlines for Deg a Chiller Plant Pressure and its Altitude Dependence Pumps in Series Vs Pumps in Parallel Overall Heat Transfer Co-Efficient Calculation

Difference between Agitation and Mixing :

Agitation Scale up [How To] Select a Condenser Tonne of Refrigeration, How to Calculate required ... Types of Agitators, Agitator's Design and Signific... [How To] Select a Motor Capacity for Agitator ► April (6) ► March (5) ► February (1) ► 2015 (5)

Like Us On Facebook

Agitation is the process of keeping a mixture that has been mixed in the proper mixed state required for the 'end' product.

Mixing refers to the actual stirring of different liquids and/or materials to blend them together into an end product or mixture. Once this mixture is 'mixed' it may require agitation to keep the mixture in the proper 'mixed' state.

So, Now i'll go into our topic,

There are two types of Agitators commonly used,

1. Mechanical Agitators, 2. Electronically Controlled Agitators, I'll demonstrate commonly used Mechanical Agitators.

Page not found The server can't be found, because the DNS lookup failed. DNS is the network service that

Recommended For You:

How to Select Motor Capacity of an Agitator? How to do Scale Up calculations? How to Design an Industrial Column?

Paddle Agitators: This is one of the most primary types of agitators with blades that reach up to the tank walls. Paddle agitators are used where an uniform laminar flow of liquids is desired.

Anchor Agitators : This simple agitator consists of a shaft and an anchor type propeller and can be mounted centrally or at an angle. It is mainly used in reactors.

Radial Propeller Agitators : Radial agitators consist of propellers that are similar to marine propellers. They consist of two to four blades that move in a screw like motion, propelling the material to be agitated parallel to the shaft.

Propeller Agitators : A propeller agitator is shaped with blades tapering towards the shaft to minimize centrifugal force and produce maximum axial flow. Propeller agitators are popular for simple mixing jobs.

Send us a message

Turbine Agitators : Yet another type of process agitator is the turbine agitator. Turbine agitators can create a turbulent movement of the

fluids due to the combination of centrifugal and rotational motion.

Helical Agitators : These agitators have blades with a twisted mechanism, just like the threads of a screw. The curves result in a vigorous motion of the fluids to be agitated. Helical agitators are most useful for mixing viscous liquids.

A simplified brief description has been tabulated below.

Agitator Type

Applications

Advantages

Disadvantages

* Mixing of Solids,

Paddle

* Heavy duty,

* Slurry Mixing,

* Apt for Slow operation,

* Used during Crystals

* Can have 2 or 4 blades

* Power Consumption is very high,

* Inefficient Mixing

forming phase during Super saturated Cooling Turbine

*Straight Blade *Pitched Blade *Curved Blade

* Liquids and Gas reactions,

* Generates high Radial Flow,

* Highly used during

* Not preferred for solvents with high

Reaction and Extraction

* Highly used for

Operations.

dispersion operations

viscosity[NMT 20 ]

*Disk Blade * Have to use in addition Screw type

to other agitators.

* Mostly used in Food processing.

* Uniform mixing of High viscous masses.

* Not preferred for im-miscible solvents.

Helical Blade

*Ribbon

* Most Probably used in

* Can handle Visco

* Low possibility for Radial

Type

Paint industry.

-elastic liquids efficiently

mixing

*Helical Screw * Increase possible heat

Anchor

* Highly used in Pharma Industry for Several Operations

transfer rate in reactors, from reactor heat transfer surface to Mass.

Gate

* Highly used for blending Operations

* Required high Efficiency Gear box, * Required high Power.

* Provides efficient

* Not preferred

Mixing and agitation control,

when both liquids and gases

* Can handle Psuedo

combine

-plastic liquids.

involves * Need to be operated

* Suitable for GLR's, Propeller

ANFD's, can handle Corrosive materials with Glass lining.

* Will increase the

at high speed to

homogeneity,

avoid solid settlings in reactors.

* Can be used in two different patterns for

* Need to be

drying and pressing.

operated at low speeds in drying operations.

Diameter of Agitator: Usually the diameter of agitator depends on the Diameter of the vessel, It is generally 1/3rd the diameter of the tank for Marine Propeller, Axial flow turbine, Turbo Propeller, Disc Blade turbine, Flat Blade turbine, Backward Blade turbine.

It is generally 4/5th of the diameter of the tank for Paddle, Anchor, Gate.

Type of Agitators and their functions:

Marine Propeller is generally an item produced by casting process in a foundry and it has 3 or 4 blades. Cast agitators have two basic advantages, uniformity of material and hard surface. These have tapering blades, and angle of blade varies from root to tip. This produces maximum axial flow. The diameter of Marine Propeller impeller is 15% to 30% of diameter of tank. These have tip speeds between 300 to 500 meters per minute.

Axial Flow Turbine, Turbo Propeller and Flat Blade Turbine have blades ranging from 3 to 6. These have tip speeds between 200 to 300 meters per minute. The diameter of impeller is 25% to 60% of tank diameter. For Axial Flow Turbine and Turbo Propeller, the angle of blade varies from 30 degrees (for less viscous liquids) to 60 degrees (for more viscous liquids). Standard angle is 45 degrees. Power requirement increases with higher pitch angle. For Flat Blade Turbine, the length of blade is 25% of diameter, and disk diameter is 60% to 70% of the diameter of impeller.

Paddle, Anchor, or Gate have only 2 blades. These extend close to the tank wall and have tip speeds between 80 to 150 meters per minute. These push and rotate the liquid in a laminar flow. There is no axial or radial mixing. The width of blade is 1/8th or 1/10th of the agitator diameter.

Number of Agitators:

There can be many number of agitators connected to a shaft, and it can be calculated as

Number of agitators = (Maximum liquid height x specific gravity) / Diameter of tank.

Gap between two Agitators = Liquid height / (Number of impellers - 0.5). Basic Design Equations for a Vertical Vessel and Agitator:

Vessel Volume = (pi x vessel dia x vessel dia x vessel length) / 4.0 Agitator Shaft length = vessel length + (vessel dia x 0.25) For Rectangular Tanks, Tank Volume = Vessel Length x Vessel Breadth x Vessel Height

Agitator Shaft length = Vessel Height

Based on geometry of vessel, many factors for impeller can be decided. Agitator Speed Marine Propeller

Axial Flow Turbine

Turbo Propeller

100 - 300 RPM

100 - 300 RPM

100 - 300 RPM

Power Number

Pumping Factor

Impeller Diameter

* 0.3 for 3 bladed impeller,

* 0.33 for 3 bladed,

1/3rd of tank

* 0.33 for 4 bladed impeller

* 0.34 for 4 bladed.

dia

* 1.35 for 3 bladed,

* 0.6 for 3 bladed,

* 1.4 for 4 bladed,

* 0.69 for 4 bladed,

1/3rd of tank

* 1.45 for 5 bladed,

* 0.78 for 5 bladed,

dia

* 1.6 for 6 bladed.

* 0.87 for 6 bladed.

* 1.35 for 3 bladed,

* 0.6 for 3 bladed,

* 1.4 for 4 bladed,

* 0.69 for 4 bladed,

1/3rd of tank

* 1.45 for 5 bladed,

* 0.78 for 5 bladed,

dia

* 1.6 for 6 bladed.

* 0.87 for 6 bladed.

Disc Blade Turbine

100 - 300 RPM

5.0

0.7 - 0.8

Flat Blade Turbine

100 - 300 RPM

5.0

0.7 - 0.85

1/3rd of tank dia 1/3rd of tank

dia Backward Blade Turbine

100 - 300 RPM

5.0

0.65 - 0.85

Paddle

50 RPM

5.0

0.03

Anchor

50 RPM

5.0

0.07

Gate

50 RPM

5.0

1.0

1/3rd of tank dia 80% of tank dia 80% of tank dia 80% of tank dia

AGITATOR COMPARISON CHART:

Today, the major concerns of the chemical and pharmaceutical industries are improving performance and reducing production costs. Agitation, mixing and heat transfer are major factors in maximizing the efficiency of a process. The various blade designs in our agitator product range have undergone significant research and testing, making it possible to use a scientific approach to agitation and heat exchange techniques that will optimize your process. The chart below illustrates the different types of blades available and the characteristics of each.

That's it.........!! Cheers..... if you understand,

Excel Sheet has been simulated for design of Agitator and you can it here,

HERE Any Queries feel free to ask,

Comments are most appreciated.!

Note: Some of the Data Interpreted here is not of my own, but from a generous Genius "Satish Lele"

Related Articles:

How to calculate Reactor Heat Transfer Area ? How to calculate Distillation Time cycle ? How to select a Vaccum pump ? How to Calculate Volume occupied by Torispherical Dish ?

About The Author Hi! I am Ajay Kumar Kalva, Currently serving as the CEO of this site, a tech geek by ion, and a chemical process engineer by profession, i'm interested in writing articles regarding technology, hacking and pharma technology. Follow Me on Twitter AjaySpectator & Computer Innovations Facebook

Share This:

CHILLING

AGITATOR

Google+

CALCULATIONS

Outlines for Deg a Chiller Plant

Types of Agitators, Agitator's Design and Signi cance

[How To] Design a Condenser

May 29, 2016

May 05, 2016

Apr 21, 2016

15 comments:

1.

UNKNOWN 1 JANUARY 2017 AT 17:37

which utility is suitable for condensing acetone vapours under vacuum and under atmposphere in condensor...chilled water 8 deg. centigrade or brine -10 degree centigrade.. Reply

Replies 1.

AJAY KUMAR 1 JANUARY 2017 AT 17:52

Hey Mr.Anonymous, if you are having two condensers, then go with chilled water for primary and chilled brine for secondary, and if you are able to maintain the vapour temperature above 15 deg C under vacuum, then go with -10 degC Brine or 5 degC chilled water, if the temperature below 15 degC then use chilled brine at -20 degC, and in case of the vacuum distillation, to have a equalisation line from secondary condenser to collection receiver, if the distillation is an atmospheric one, directly go with RT water at below 30 degC,

2.

ANSHU BHARGAVA 2 JANUARY 2017 AT 09:51

Can you explain theoretically and calculate and tell how to select utility as per the above post.pls. give ur mail id so that i can share the sketch..

3.

AJAY KUMAR 2 JANUARY 2017 AT 21:13

using a better utility for condenser will enhance the rate of distillation, for a chilled brine at -10 deg C, the temperature difference can be considered as 7-8 deg C, and for a utility like chilled water having a inlet temperature of 8 deg C, the temp difference will be around 3-4 degC, because the reaction mass temperature will be around 15-20 degC under vacuum, so mostly the vapours will reach equillibrium with utility outlet, and in the process of condensing the vapour will exchange only latent heat, whereas in case of -10 degC brine, there will be exchange of sensible heat also, and if you want to calculate it theoretically

then read the post in this link, then you will get a clear idea, http://pharmacalc.blogspot.com/2016/09/how-to-calculate-rate-of-distillation.html try to do a reverse calculation baon the fixed rate of distillation and find the LMTD of both cases, which uses brine at -10degC and chilled water at 8degC, then you will come to know the difference.

Reply

2.

ANONYMOUS 6 JANUARY 2017 AT 22:26

Hello sir, I am chemical engineering student I am doing my final year project on extraction of oil from slurry in oil refineries.can you suggest us some ideas Reply

3.

AJAY KUMAR 7 JANUARY 2017 AT 06:59

so i think, it is something like Lube oils refining, right?? Thats a good one, and i too tried that during my project but finally got diverted, Give your best good luck, and regarding extraction any possible help i'll do, mail me @ [email protected] Reply

4.

HIRENKUMAR KAYASTH 1 FEBRUARY 2017 AT 19:55

Please tell me how to do piping? How to design pipeline Header and Tappings from it? Reply

Replies 1.

AJAY KUMAR 1 FEBRUARY 2017 AT 20:41

A x V = A1 x V1 + A2 x V2 + A3 x V3 +...................... But, V = V1 = V2 = V3 = .............. [this is as per thumb], A = A1 + A2 + A3 +................ D^2 = D1 ^2 + D2 ^2 + D3 ^2 + .............. that's it, the number of tappings given should satisfy the above derived eqn.

Regards, PHARMA ENGINEERING

Reply

5.

ANONYMOUS 3 MAY 2017 AT 14:52

what is the major difference between impeller,propellerand agitator Reply

Replies 1.

AJAY KUMAR 4 MAY 2017 AT 20:38

Mostly there wont be anything like a Propeller, may be i've mentioned above that's just for understanding purpose, because Propeller is what you see in a table fan, and the agitator that was usually called as propeller in pharma industry is strictly called as Retreat curve agitator,

Coming to your question, Impeller is nothing but an agitator, and for example if an retreat curve is having two agitators then it is said to have 2 impellers. That's it.

Reply

6.

ANSHU BHARGAVA 5 MAY 2017 AT 13:01

How can we calculate power for propeller & anchor used in glass lined reactor.... Reply

Replies 1.

AJAY KUMAR 6 MAY 2017 AT 10:04

Let it be a 10KL GLR, and the dia be 2.5m, and RPM is 110, by thumb dia of propeller will be 1/3rd of reactor dia, For Propeller, D = 2.5/3 = 0.83m, N = 110 rpm, rho = 1000 Cu.m / Kg, Np = 1.5 P = 1.5 x 1000 x ( ( 110/60 ) ^ 3 ) x ( 0.83 ^ 5 ) = 3641 Watts = 3.64 KW, For Anchor. D = 2.5 x 0.8 = 2m, N = 48 rpm, Np = 5, P = 5 x 1000 x ( (48/60) ^ 3 ) x ( 2 ^ 5 ) = 81920 Watts = 81.9 KW. That's it..........!!!!

Reply

7.

ANUJ GANDHI 4 JULY 2017 AT 17:31

Hi, Great site, and great work. We are a 30 year old manufacturing firm specializing in chemical and pharmaceutical reactors. We are currently looking for professionals who can independently design agitators for the process and mechanical aspect. If you know any such individuals, please ask them to reach out to me at [email protected]. Cheers Anuj Reply

8.

ANSHU BHARGAVA 7 JULY 2017 AT 17:08

how can we design spray ball ..how to select number of holes and flow from holes in spray ball? Reply

Replies 1.

AJAY KUMAR 12 JULY 2017 AT 14:07

Hello, as like previously mentioned, A*V = ( A1 * V1 ) + ( A2 * V2 ) + ( A3 * V3 )+................, V = V1 = V2 = V3 = ............, So, A = A1 + A2 + A3 + ........, (D^2) = (D1 ^2) + (D2 ^2) + (D3 ^2) + ........, D is line size, D1, D2, D3,....... are nozzle sizes, for how many nozzles the equation satisfied, those many nozzles you need to consider for a spray ball. Regards, PHARMA ENGINEERING

Reply

Add comment

Enter your comment...

Comment as:

Publish

M Erwin Yamashita (Google)

Preview

Sign out

Notify me

Links to this post Create a Link

Newer Post

Older Post

OUR TEES

ABOUT

Hi! I am Ajay Kumar Kalva, Currently serving as the CEO of this site, a tech geek by ion, and a chemical process engineer by profession, i'm interested in writing articles regarding technology, hacking and pharma technology.

agitator

Calculations

chilling

design

Documentation

DQ

iq

network analysis

Power consumption reaction kinetics

Followers

Us by Promoting Us

Labels

softwares

Ikuti

Created By Sora Templates | Distributed By Ajay Kumar Kalva

FTA OQ

pressure calculation scaleups

how to

pumps

simulation

timecycle for heating/cooling

Tons of Refrigeration

Pengikut (0)

OOS

Condenser

utilities

vacuum pump