Underwater Welding Ppt 2b463u

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3i3n4

Overview 26281t

& View Underwater Welding Ppt as PDF for free.

More details 6y5l6z

- Words: 986

- Pages: 27

1 Study of Various Methods and Parameters Involved in Underwater Welding Subject Code-ME1637 Under the guidance of: Dr. A K Das

Presented By: Abhishek Jain 1201076

Department of Mechanical Engineering National Institute of Technology

Contents

Introduction

Classification

Wet Welding

Dry Welding

Advantages

Disadvantages

Schematic Diagram of Apparatus Required

Risks

Applications

Effect of Wet environment on welds

Porosity Curve

References

2

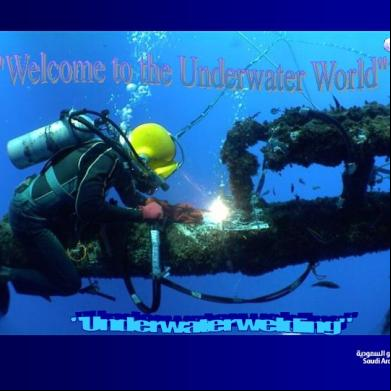

INTRODUCTION TO UNDERWATER WELDING

3

4

How can big ships or underwater Rigs be repaired ???? We can’t lift ships and then repair them.

INTRODUCTION

Underwater welding is an important tool for underwater fabrication works.

In 1946, special waterproof electrodes were developed in Holland by ‘Vander Willingen'’.

In recent years the number of offshore structures including oil drilling rigs, pipelines, platforms are being installed significantly.

5

CLASSIFICATION

Under water welding can be classified as :

i.

Dry welding

ii.

Wet welding

6

DRY WELDING

7

A chamber is created near the area to be welded and the welder does the job by staying inside the chamber.

It produces high quality weld ts .

The gas-tungsten arc welding process is used mostly for pipe works

Gas metal arc welding is the best process for this welding.

CLASSIFICATION OF DRY WELDING There are two basic types of dry welding : i.

Hyperbaric welding

ii.

Cavity welding

8

Hyper baric welding: It

is carried out in chamber sealed around the structure to be welded filled with a gas to push water back.

Gas

generally used is a breathable mixture of helium and oxygen.

The

area under the floor of the habitat is open to water, so hyper baric welding is termed as

“HABITAT-WELDING”

An image for Habitat Welding

9

1 0

Hyper = High, Baric = Pressure Hyper Baric welding means high Pressure Welding

Cavity welding:

Cavity welding is another approach to weld in water free environment.

Conventional arrangements for feeding wire and shielding gas

Introducing cavity gas and the whole is surrounded by a trumpet shaped nozzle through which high velocity conical jet of water es.

It avoids the need for a habitat chamber and it lends itself to automatic and remote control.

The process is very suitable for flat structures.

1 1

Advantages:-

1 2

Welder/diver is safe.

Non destructive testing of weld is easy.

Good quality welds are formed.

Surface monitoring of welders condition can be done.

Disadvantages:

The habitat welding requires large quantities of complex equipment and much equipment on the surface

Cost is extremely high hence cannot be afforded by normal or small firms.

Large habitat for underwater hyperbaric welding

1 3

WET WELDING

1 4

Key technology for repairing marine structure

Welding is performed under water directly exposed to the wet environment

Increased freedom movement makes more effective, efficient and economical

Supply is connected to the welder/driver via cables or hoses

1 5

Complete insulation of the cables and hoses are essential in case to prevent the chance for electric shock

MMA (Manual Metal Arc) welding is commonly used process in the repair of offshore platforms.

PRINCIPLE OF OPERATION

The work-piece is connected to the positive side of dc source (Anode) and electrode to the negative side (Cathode).

The two parts of the circuit are brought together and then slightly separated.

1 6

An electric current occurs in the gap and causes a sustained spark which melts the bare metal forming a weld pool.

The flux covering the electrode melts to provide a shielding gas.

Arc burns in the cavity formed inside the flux covering, which is designed to burn slower than the metal barrel to the electrode.

1 7

Advantages

The versatility and low cost.

Less costlier than dry welding.

Speed with which it is carried out.

No enclosures so no time is lost for building.

1 8

Disadvantages

Rapid quenching of the weld metal by the surrounding water.

Welders working under water are restricted in manipulating arc.

Hydrogen embrittlement causes cracks.

Poor visibility due to water contaminance.

1 9

RISKS V/S PRECAUTIONS Risk

of electric shock so precaution is taken for checking the electrical insulation of electrical welding equipments.

Hydrogen

and oxygen are produced by the arc in wet welding which are potentially explosive so precaution must be taken to avoid the build up of pockets of gas

The

life or health of the welder will be in risk from nitrogen introduction into the blood stream, hence precautions include the provision of an emergency air cylinder for the welder.

2 0

APPLICATIONS

Offshore construction for tapping sea resources.

Temporary repair work caused by ship’s collisions, or unexpected accidents.

Salvaging vessels sunk in the sea.

Construction of large ships beyond the capacity of existing docks.

Maintenance of oil rigs.

2 1

Figure showing schematic diagram for 2 underwater welding or cutting 2

EFFECT OF WET ENVIRONMENT

2 3

Water dissociates into Oxygen and Hydrogen which dissolves in the molten pool causing: Gas Inclusion Defects Porosity Water Inclusion as after some times hydrogen combines with oxygen forming water vapor.

(a)

(b)

V-groove wet weld deposited at 100 m depth (a) and its radiographic image (b)

Graph Between the Porosity and Water 2 Pressure during welding 4

CONCLUSION

2 5

• Most Underwater Structures are formed using this method as the method is economical, flexible, versatile, Speedy. • Combined additions of titanium, boron, and manganese increased the tensile strength of the steel wet welds due to microstructural refinement and increased hardenability thus providing new dimensions to underwater structures

REFERENCES

www.Wikipedia.org

Paper on Underwater Welding-Jyotsana Dutta Majumdar (IIT KGP 2006)

Manual for underwater welding, US Navy

www.howstuffworks.com

2 6

2 7

THANK YOU

Presented By: Abhishek Jain 1201076

Department of Mechanical Engineering National Institute of Technology

Contents

Introduction

Classification

Wet Welding

Dry Welding

Advantages

Disadvantages

Schematic Diagram of Apparatus Required

Risks

Applications

Effect of Wet environment on welds

Porosity Curve

References

2

INTRODUCTION TO UNDERWATER WELDING

3

4

How can big ships or underwater Rigs be repaired ???? We can’t lift ships and then repair them.

INTRODUCTION

Underwater welding is an important tool for underwater fabrication works.

In 1946, special waterproof electrodes were developed in Holland by ‘Vander Willingen'’.

In recent years the number of offshore structures including oil drilling rigs, pipelines, platforms are being installed significantly.

5

CLASSIFICATION

Under water welding can be classified as :

i.

Dry welding

ii.

Wet welding

6

DRY WELDING

7

A chamber is created near the area to be welded and the welder does the job by staying inside the chamber.

It produces high quality weld ts .

The gas-tungsten arc welding process is used mostly for pipe works

Gas metal arc welding is the best process for this welding.

CLASSIFICATION OF DRY WELDING There are two basic types of dry welding : i.

Hyperbaric welding

ii.

Cavity welding

8

Hyper baric welding: It

is carried out in chamber sealed around the structure to be welded filled with a gas to push water back.

Gas

generally used is a breathable mixture of helium and oxygen.

The

area under the floor of the habitat is open to water, so hyper baric welding is termed as

“HABITAT-WELDING”

An image for Habitat Welding

9

1 0

Hyper = High, Baric = Pressure Hyper Baric welding means high Pressure Welding

Cavity welding:

Cavity welding is another approach to weld in water free environment.

Conventional arrangements for feeding wire and shielding gas

Introducing cavity gas and the whole is surrounded by a trumpet shaped nozzle through which high velocity conical jet of water es.

It avoids the need for a habitat chamber and it lends itself to automatic and remote control.

The process is very suitable for flat structures.

1 1

Advantages:-

1 2

Welder/diver is safe.

Non destructive testing of weld is easy.

Good quality welds are formed.

Surface monitoring of welders condition can be done.

Disadvantages:

The habitat welding requires large quantities of complex equipment and much equipment on the surface

Cost is extremely high hence cannot be afforded by normal or small firms.

Large habitat for underwater hyperbaric welding

1 3

WET WELDING

1 4

Key technology for repairing marine structure

Welding is performed under water directly exposed to the wet environment

Increased freedom movement makes more effective, efficient and economical

Supply is connected to the welder/driver via cables or hoses

1 5

Complete insulation of the cables and hoses are essential in case to prevent the chance for electric shock

MMA (Manual Metal Arc) welding is commonly used process in the repair of offshore platforms.

PRINCIPLE OF OPERATION

The work-piece is connected to the positive side of dc source (Anode) and electrode to the negative side (Cathode).

The two parts of the circuit are brought together and then slightly separated.

1 6

An electric current occurs in the gap and causes a sustained spark which melts the bare metal forming a weld pool.

The flux covering the electrode melts to provide a shielding gas.

Arc burns in the cavity formed inside the flux covering, which is designed to burn slower than the metal barrel to the electrode.

1 7

Advantages

The versatility and low cost.

Less costlier than dry welding.

Speed with which it is carried out.

No enclosures so no time is lost for building.

1 8

Disadvantages

Rapid quenching of the weld metal by the surrounding water.

Welders working under water are restricted in manipulating arc.

Hydrogen embrittlement causes cracks.

Poor visibility due to water contaminance.

1 9

RISKS V/S PRECAUTIONS Risk

of electric shock so precaution is taken for checking the electrical insulation of electrical welding equipments.

Hydrogen

and oxygen are produced by the arc in wet welding which are potentially explosive so precaution must be taken to avoid the build up of pockets of gas

The

life or health of the welder will be in risk from nitrogen introduction into the blood stream, hence precautions include the provision of an emergency air cylinder for the welder.

2 0

APPLICATIONS

Offshore construction for tapping sea resources.

Temporary repair work caused by ship’s collisions, or unexpected accidents.

Salvaging vessels sunk in the sea.

Construction of large ships beyond the capacity of existing docks.

Maintenance of oil rigs.

2 1

Figure showing schematic diagram for 2 underwater welding or cutting 2

EFFECT OF WET ENVIRONMENT

2 3

Water dissociates into Oxygen and Hydrogen which dissolves in the molten pool causing: Gas Inclusion Defects Porosity Water Inclusion as after some times hydrogen combines with oxygen forming water vapor.

(a)

(b)

V-groove wet weld deposited at 100 m depth (a) and its radiographic image (b)

Graph Between the Porosity and Water 2 Pressure during welding 4

CONCLUSION

2 5

• Most Underwater Structures are formed using this method as the method is economical, flexible, versatile, Speedy. • Combined additions of titanium, boron, and manganese increased the tensile strength of the steel wet welds due to microstructural refinement and increased hardenability thus providing new dimensions to underwater structures

REFERENCES

www.Wikipedia.org

Paper on Underwater Welding-Jyotsana Dutta Majumdar (IIT KGP 2006)

Manual for underwater welding, US Navy

www.howstuffworks.com

2 6

2 7

THANK YOU