0065rtd_thermowell 1l1u3q

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3i3n4

Overview 26281t

& View 0065rtd_thermowell as PDF for free.

More details 6y5l6z

- Words: 30,002

- Pages: 80

Product Data Sheet

00813-0301-2654 Rev. June 20, 2001

Resistance Thermometers and Thermocouples

Temperature Sensors and Accessories Volume 3 NEW • New connection head with IP 68 • Extended DIN thermowell offering • Extended temperature range up to 600 °C for Series 65 RTDs with better long-term stability • New approvals for hazardous area applications • Extended extension piece offering • Calibration for measurement system: Sensor with connected transmitter

HSG-008_2C.TIF

• Extended accessories offering: “Complete Point SolutionsTM“ including assemblies with sensors, connection heads, extensions, and stand-alone thermowells or with mounted-on transmitter Models 144, 244, 644, or 3144/ 3244MV

HSG-004.tif

For Further Information about Rosemount Products: www.rosemount.com or www.fisher-rosemount.de/rtemp

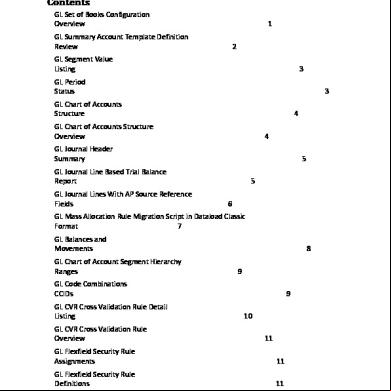

Table of Contents SECTION 1: INTRODUCTION Overview .......................................................................................................................................................... 3 General Ordering Information ........................................................................................................................ 4

SECTION 2: SENSORS AND ASSEMBLIES Rosemout “Complete Point SolutionsTM” ........................................................................................................ 5 Mounting Configurations ........................................................................................................................ 7 Series 65 Platinum RTD ................................................................................................................................. 9 Series 65 Platinum RTD WITHOUT Thermowell ......................................................................................... 9 Series 65 Platinum RTD WITH Series 95 Tubular Thermowell .................................................................. 15 Series 65 Platinum RTD WITH Series 96 Weld-in Barstock Thermowell ................................................... 22 Series 65 Platinum RTD WITH Series 96 Threaded Barstock Thermowell ................................................ 26 Series 65 Platinum RTD WITH Series 96 Flanged Barstock Thermowell .................................................. 31 Series 185 Thermocouple ..................................................................................................................... 36 Series 185 Thermocouple WITHOUT Thermowell (Ordering Information) ................................................ 37 Series 185 Thermocouple WITH Series 95 Tubular Thermowell (Ordering Information) ....................... 39 Series 185 Thermocouple WITH Series 96 Weld-in Barstock Thermowell (Ordering Information). .......... 43 Series 185 Thermocouple WITH Series 96 Threaded Barstock Thermowell (Ordering Information) ........ 45 Series 185 Thermocouple WITH Series 96 Flanged Barstock Thermowell (Ordering Information) .......... 48

SECTION 3: CALIBRATION Sensor-to-Transmitter Matching ........................................................................................................... 52 Calibration Options with Works Certificate .................................................................................................. 53 Calibration Options with DKD Certificate ..................................................................................................... 55 Calibration Certificates for Measuring Systems ........................................................................................... 57

SECTION 4: MOUNTING ACCESSORIES General Ordering Information ....................................................................................................................... 59 Connection Heads .......................................................................................................................................... 60 Extensions ...................................................................................................................................................... 63 Compression Fittings ..................................................................................................................................... 65 Thermowells ................................................................................................................................................... 66 Series 95 Tubular Thermowells (Ordering Information) .............................................................................. 67 Series 96 Weld-in Barstock Thermowells (Ordering Information) ............................................................... 69 Series 96 Thread-Mounted Barstock Thermowells (Ordering Information) ................................................ 70 Series 96 Flange-Mounted Barstock Thermowells (Ordering Information) ................................................. 72 Thermowell Strength Calculation Overview ................................................................................................. 74 Questionnaire ................................................................................................................................................. 75

SECTION 5: HAZARDOUS AREA APPROVALS CENELEC/KEMA Flameproof Approval ............................................................................................... . 77 CENELEC/ISSeP Flameproof Approval ................................................................................................ 77 BASEEFA Type N Non-Incendive Approval .................................................................................................. 77 CENELEC Intrinsically Safe Approval .......................................................................................................... 78

SECTION 6: IMPORTANT INFORMATION Sales Office Addresses .................................................................................................................................... 79

THERMOWELL STRENGTH CALCULATION REQUEST FORM (CDS)

2

Introduction

Section 1

Introduction

This Product Data Sheet (PDS) is intended to be a complete reference and ordering guide for Rosemount Temperature Sensors, Assemblies, and Accessories.

Section 2 SENSORS AND ASSEMBLIES Includes descriptions, specifications, and ordering information for Series 65 RTD, and Series 185 Thermocouples. It also includes information for ordering sensors, connection heads, extensions, and thermowells as complete assemblies.

Section 3 CALIBRATION Includes test specifications and ordering information for calibrated Series 65 RTDs and Series 185 Thermocouples. It also includes information for use of Calendar van Dusen constants for sensor-to-transmitter matching on calibrated Series 65 Platinum RTD.

Section 4 MOUNTING ACCESSORIES Includes descriptions, specifications and ordering information for extensions, connection heads and thermowells.

Section 5 HAZARDOUS AREA APPROVALS Includes descriptions of the CENELEC Flameproof, BASEEFA Type N Non-Incendive, and Intrinsic Safety Approvals. For assistance regarding the information in this PDS, the European Applications Group at either of the addresses below:

Rosemount Temperature GmbH Frankenstrasse 21 63791 Karlstein, Phone: +49 6188 992-0 Fax: +49 6188 992-112 Internet: www.rosemount.com

Overview This PDS entitled “ Temperature Sensors and Assemblies – Volume 3” contains details of temperature assemblies which confirm to German DIN standards. Many of the assemblies can be fitted with a Rosemount temperature transmitter. Series 65 and 185 assemblies are designed to meet the critical parameters of the following international standards: DIN EN 60751 (IEC 751) describes the electrical characteristics for platinum RTD temperature sensors. DIN EN 60584 (IEC 584) describes thermocouple characteristics. DIN 43772 specifies process connections, dimensions, and ratings of thermowells. DIN 43761 and 43762 define the construction of the temperature sensors (measuring inserts) themselves. Series 65 Platinum RTD temperature sensors are available with a standard measuring range from -50 to +450 °C with an option of an extended range capability from -196 to +600 °C, utilizing a wire-wound element. The wire-wound version offers better longterm stability and improved mechanical robustness against vibrations. Series 185 Thermocouples are available in types E, J, K, N, and T. The hot junctions are available as single elements grounded or ungrounded, and as dual elements ungrounded and isolated. Enhanced performance and optimal temperature measurement accuracy is available for Series 65 temperature sensors coupled with our range of Smart temperature transmitters through calibration schedules and Callendar van Dusen constants into the transmitters. Both the Series 65 and 185 sensors are manufactured from mineral insulated cable. All sensors are supplied in a variety of lengths and temperature ranges, with flying leads, terminal blocks, or ½-inch NPT spring-loaded adapter lead wire terminations. In addition to complete assemblies, this PDS offers a selection of separate accessory hardware including connection heads, extensions, and thermowells.

Fisher-Rosemount Ltd. Heath Place Bognor Regis, PO22 6SH, England Phone: +44 1243 863 121 Fax: +44 1243 845 202 E-mail: [email protected]

Rosemount and the Rosemount logo are ed trade marks of Rosemount Inc. Inconel and Monel are ed trade marks of International Nickel Co. Hastelloy is a ed trademark of Cabot Corp.

3

General Ordering Information

Using this data sheet, you can order complete temperature sensor systems, which include sensors, thermowells, extensions, and connection heads. You can also order each of these items separately, for the use with either an existing sensor or thermowell.

Hsg-007.tif

The following flowchart describes the ordering process for complete sensor systems – sensors with mounted-on thermowells – which can be found in different ordering tables, depending on the option chosed.

Figure 2: Sensor Product Range Overview.

Figure 1: Ordering Flowchart.

Start (Select one) ▲

▲

A sensor for an existing thermowell is required

▲

A sensor with a tubular thermowell is required

A sensor with a barstock thermowell is required ▲

Select the thermowell mounting style ▲

▲

▲

Threaded

Weld-in

Flanged

▲

▲

▲

▲

▲

Select a sensor (without thermowell) from the tables in Section 2: See page 13 for Series 65, and page 37 for Series 185

Select a sensor with tubular thermowell from the tables in Section 2: See page 18 for Series 65, and page 39 for Series 185

Select a sensor with weld-in barstock thermowell from the tables in Section 2: See page 24 for Series 65, and page 43 for Series 185

Select a sensor with threaded barstock thermowell from the tables in Section 2: See page 28 for Series 65, and page 45 for Series 185

Select a sensor with flanged barstock thermowell from the tables in Section 2: See page 33 for Series 65, and page 48 for Series 185

▲

▲

▲ ▲

▲

▲

Introduction

General Ordering Information

Finish

4

Section Sensors and Assemblies

Rosemount “Complete Point SolutionsTM”

To order individual mounting accessories, refer to Section 4: “Mounting Accessories”.

Figure 3: Sensors.

HSG_002BW.tif

The Rosemount Complete Point Solutions program provides fully-engineered measurement solutions, combining the best products and practices for improved performance, reliability, and cost of ownership. Series 65 RTD and Series 185 Thermocouple Temperature Sensors may be ordered as complete assemblies including sensors, connection heads, extensions, thermowells. One assembly model number, derived from one ordering table, completely defines the sensor type, the material, the length, and the style both of the extension fittings and of the thermowells. All sensor assemblies are sized and inspected by Rosemount to ensure complete component compatibility and performance.

These sensor assemblies can be used with Rosemount Series 144, 244, 644, and 3144/3244MV transmitters. To order Rosemount transmitters, refer to the appriopriate Transmitter Product Data Sheet, see information on page 78 in Section 5.

Sensors and Assemblies

2

Hsg-005.tif

Figure 4: Transmitters and Connection Heads.

5

Sensors and Assemblies

Figure 5: Schematic of Complete Sensor Assemblies.

Sensors and Assemblies

Head- or FieldMounted Transmitters

Sensor with Flying Leads, Terminal Block, or Spring-Loaded Adapter 2 x ½-inch NPT

IP 68, IP 65, or IP 54 Connection Heads

Integrated or Stand-alone Extensions

25_3b_abb05.tif

Threaded and Flanged Tubular Thermowells; Weld-in, Threaded, or Flanged Barstock Thermowells

6

Sensors and Assemblies

SERIES 65 PLATINUM RTD’S AND SERIES 185 THERMOCOUPLES You may order the Series 65 RTD’s and Series 185 Thermocouples with flying leads, a terminal block, or a ½-inch NPT spring-loaded adapter. Both versions of sensors with flying leads, with or without springs on the DIN-integral mounting plate, are designed to be used with a head-mount temperature transmitter attached directly to the sensor. The flying lead configuration facilitates the removal of sensor and transmitter as one assembly. The last generation of head-mount Rosemount transmitters (Model 244 and 644 Rev. 5, and the new Model 144) requires a measuring insert with flying leads and with no springs on DIN-integral mounting plate. The sensors provided with a terminal block require the mounting of the transmitter into the cover of connection head. The sensor and the transmitter are connected by additional leads.

The sensors with a ½-inch NPT spring-loaded adapter are for use in configurations where the sensor and the transmitter are mounted separately, or where a Rosemount field-mount transmitter is being used. The sensor with spring-loaded adapter ensures good ground with the thermowell. This shortens the response time and increases the resistance against vibrations.

Sensors and Assemblies

Mounting Configurations

Hazardous area approvals are available for all three types of sensors, but they depend on the configuration of the entire temperature measurement assembly (see Section 5: “Hazardous Area Approvals”).

Figure 6: Series 65 RTD and Series 185 Thermocouple Lead Wire Configurations. Series 65 RTD Single Element

Series 185 Thermocouple Dual Element 4 white

Pt 100

5 red

6 white

Single Element, Grounded

6 red 1 white

3 red 4 red

Wiring Diagram 4-Wire Circuit

1 white 2 red

Pt 100

Single Element, Ungrounded

25_3b_abb06.tif

Pt 100

3 red

Wiring Diagram 2 x 3-Wire Circuit

Dual Element, Ungrounded, Isolated

7

Sensors and Assemblies

Figure 7: Series 65 RTD and Series 185 Thermocouple Sensors – Dimensional Drawings. Flying Leads CENELEC EEx d Flameproof Approval

Sensors and Assemblies

41

No Approval

41

41

33

25

41

10

25

33

10

21

21

31

31

8.00 8.00-0.05

8.00

8.00-0.05

L

L

L

6

L

6

6

6

Code 1 / Add. Code ED

Code 0

Code 1

Sensor Lead Wire Termination Code 0 / Add. Code ED

Adapter 2 x ½-inch NPT, Spring-Loaded

Terminal Block CENELEC EEx d Flameproof Approval

No Approval

CENELEC EEx d Flameproof Approval

41

41

33

33

10

25 31

8.00

Detail View Measuring Tip 8 mm

11

8.00-0.05

L

L L 60

8 6

6

6

Code 2

Code 3 / Add. Code E9

Sensor Lead Wire Termination

Series

65 Single Element 65 Dual Element 185 Single Element 185 Dual Element Dimensions in millimeters

8

Sensor Outer Diameter

Number of Lead Wires

6.0 / 8.0 6.0 / 8.0 6.0 / 8.0 6.0 / 8.0

4 6 2 4

L

Lead Wire Length Single Element Codes 0, 1 Code 3 100 100 100 100

150 150 150 150

= Sensor Length

Dual Element Codes 0, 1, 3 200 200

25_3b_abb07.tif

Code 2 / Add. Code ED

Sensors and Assemblies

SPECIFICATIONS Immersion Length 60 mm minimum usable depth of immersion when tested according to IEC 751 Insulation Resistance 1,000 Megohms minimum insulation resistance when measured at 500 V dc and at room temperature Sheath Material 1.4541 (AISI 321 SST) with mineral-insulated cable construction. Ni-inner conductors. Filling of magnesium oxide powder between conductors and sheath Lead Wire PTFE insulated, silver-coated copper-wire strands 1 x 0.22 mm2 Identification Data The model and serial numbers are marked on the bottom side of sensor DIN-mounting plate or engraved directly on the spring-loaded adapter Self-Heating 0.15 K/mW when measured by the method defined in DIN EN 60751:1996 Temperature Range Depending on the sensor, the temperature range is either -50 to +450 °C with a thin-film RTD or -196 to +600 °C with a wire-wound RTD Nominal Resistance RTD’s with platinum measurement winding are used. In accordance with DIN EN 60751, the nominal resistance is defined as follows: • 100 Ω RTD at 0 °C • Temperature coefficient 3.85 x 10-3 (Ω x °C/Ω), averaged between 0 and 100 °C Limit Deviations Tolerance Class B: t = ± (0.30 + 0.005 x t) valid for the complete temperature range from -196 to +600 °C. Tolerance Class A: t = ± (0.15 + 0.02 x t) valid for the complete temperature range from -50 to +450 °C. Restricted tolerances beyond that can be achieved at a specified temperature point or range by selection. The long-term temperature at restricted tolerances is limited to 450 °C.

SERIES 65 PLATINUM RTD THERMOWELL

WITHOUT

With the Series 65 Platinum RTD for installation into a thermowell, the following thermometer types can be implemented:

Stand-Alone Sensor with the Following Options: • 3 versions of lead wire termination: - Flying leads with or without springs for direct mounting of head-mount transmitters - Terminal block - Spring-loaded adapter, 2 x ½-inch NPT • Standard without approval, resp. with manufacturer declaration for (Ex i) use in zone 1 acc. to DIN EN 50014 and DIN EN 50020. For compliance with the EEx d CENELEC/KEMA Flameproof Approval, the captive flame arrestor insert must be fully engaged into the suitable Rosemount connection head • 1 Pt 100 in 4-wire-connection and 2 Pt 100 in 3-wire-connection • Max. temperature with thin-film RTD up to 450 °C and with wire-wound RTD up to 600 °C • Standard diameter of the measuring insert is 6 mm. For larger sizes of bore in the thermowell, a bush with an outer diameter of 8 mm can be welded on the measuring insert tip (60 mm long) • As sensors can be used universally in many complete assembly designs, the sensor is basis for the standardized sensor lengths. The standard sensor lengths correspond to DIN 43772 (in mm): 145, 205, 315, 375, 405, 435, 555. Non-standard lengths are available up to 9995 mm • Sensor can be removed while the system is running without dismantling the complete assembly.

Sensor with Connection Head, without Extension • By combining tubular thermowells, see temperature sensors and ordering information on page 18 • With sealing screw M24 x 1.5 at the bottom of the connection head, to ensure IP ratings 54, 65 resp. 68. Optionally, a compression fitting with different thread sizes for sensor mounting into process can be ordered. Standard selection of compression fittings can be found in the ordering table on page 65 • Head-mount transmitters Rosemount model 144H, 244EH, and 644H to be integrated into connection heads • For the determination of the correct sensor length for thermowells on customer´s site, the different sizes of connection heads have to be taken into . Rosemount connection head acc. to DIN 43729 Form A, and all other connection heads acc. to DIN 43729 Form B 9

Sensors and Assemblies

Series 65 Platinum RTD

Sensors and Assemblies

Sensor with Connection Head and Extension

HSG_008BW.tif

Sensors and Assemblies

• DIN standard or nipple-union-nipple extension with ½-inch NPT can be ordered • By combining barstock thermowells, see temperature sensors acc. to ordering information on pages 13 and 37. Depending on the instrument connection of thermowells on customer‘s site, the following extension connection threads are available: - Parallel: M24 x 1.5, ½-inch BSPF, M18 x 1.5, M20 x 1.5 and - Tapered: ½-inch BSPT and ½-inch NPT - Without additional thermowell as version with stand-alone sensor

Figure 8: Sensors and Thermometers.

Table 1:

Transmitters Mounting into Connection Heads.

Transmitters

Connection Heads

Sensor Connections

Rosemount GR-A/BL TZ-A/BL BUKH GN-BL Aluminum Aluminum Stainless Stainless AlumiAlumi- Poly- AlumiLCD Meter Steel Steel LCD num num amide num Cover Meter Cover Codes

C, D

Flying Leads

Terminal Block

0 (new) 1 (old)1)

2

1, 2

G, H

3, 4

J

L

T

U

o -

o o o -

o -

o o o -

o o o o o o

o o o o o o

o -

o o o -

-

o o o

-

-

-

-

o -

o o o

-

o o o

-

-

Installation of 1 Transmitter 144H 144H 244EH 244EH 644EH 644EH

o o o -

Installation of 2 Transmitters 144H 244EH 644H (1) 2)

o2) o2) o2)

For sensor replacement only. Aluminum extension ring for dual-transmitter mounting required.

10

„o“ Combination allowed „-“ Combination not allowed

Sensor with Spring-loaded Adapter 2 x ½-inch NPT and Nipple-Union Extension, without Connection Head

New plants are often fitted with temperature sensors in two stages:

• In combination with barstock thermowells, see temperature sensors acc. to ordering information on pages 13 and 37, standard with connection thread ½-inch NPT • Without additional thermowell as version with stand-alone sensor • For mounting on the field-mount Rosemount transmitter Model 3144/3244MV • Optionally with EEx d CENELEC/ISSeP Flameproof Approval

• Installation of thermowells in connection with the vessel/pipeline construction • Addition of a sensor during a later instrumentation phase

If you wish to order individual parts such as connection heads and extensions, refer to Section 4: “Mounting Accessories.” Barstock thermowells have a thread to accommodate an appriopriate extension tube and an adapter for the connection head. We recommend that the Extension Length N should always be selected so that the Immersion Length U, the Extension Length N and the fixed length of 26 resp. 41 mm in the connection head add up to the Standard Sensor Length L.

L (Standard)

=

U

+

N

+ 41

(depends on (generally, DIN process) flexible) A-head

or

This procedure makes it possible to realize a uniform instrumentation concept in large plants. The following ordering table contains temperature sensors, which are suitable for installation into existing thermowells. To order individual thermowells, please refer to ordering tables on pages 67 up to 72.

NOTE: All above mentioned constructive designs are also valid for Series 185 Thermocouples. The two series differ only by the selection of the sensors. Series 185 Thermocouples are described in details on page 36.

26 DIN B-head

The thread length of extension connection thread with tapered thread size differs between hand and wrench tight, this affects the calculation of the suitable sensor length. The standardization of the type and the length of the sensor benefits the customer in of price and delivery time. A reduction in the number of different sensor lengths used in the plant also reduces spares inventory requirement. The exchange can be effected during the operation, without gearing into the medium.

Applications • • • • •

General machinery and apparatus engineering Chemical process engineering Power generation and heat distribution Food and beverage industries Sanitary, heating and air conditioning systems

11

Sensors and Assemblies

Sensors and Assemblies

Sensors and Assemblies

Figure 9: Series 65 RTD and Series 185 Thermocouples WITHOUT Thermowell – Dimensional Drawing.

Sensor Design

Connection Heads Model: Rosemount Model: BUKH Aluminum, Stainless Steel Polyamide Codes C, D, G, H, 1, 2, 3, 4 Code T

Model: TZ-A/BL Aluminum Code L

Sensors and Assemblies

Mounting Example

Model: GR-A/BL Aluminum Code J

Model: GN-BL Aluminum Code U

Sensor Lead Wire Terminations, see Figure 7

Extensions and Options Welded-on Threaded Connections Parallel (G, M) Tapered (R, NPT) Codes A, C, E, T Codes B, D

No Extension with Sealing Screw – Code V (Fig.); without Sealing Screw – Codes N, L, W

No Extension with Compression Fitting Code V, Add. M10-M17

Nipple-Union-Nipple Code F

Nipple-Union Code J

Measuring Insert Tips

L

= Sensor Length

Welded-on Sleeve 8 mm Add. Code M02

N K = Extension Length (tapered) NZ = Extension Length (parallel) Dimensions in millimeters

12

25_3b_abb09.tif

Straigth 6 mm

Sensors and Assemblies

Ordering Information: Series 65 Platinum RTD WITHOUT Thermowell (Part 1 of 2) 0065 Code C (2) D (2) G (2) H (2) J (2) L (2) T (2) U (3) 1 2 3 4 N Code 0 1 2 3 (4) Code 1 2 3 4 Code A B C D E T F J N L W V Code 0000 0080 0110 0135 0149 XXXX Code N Code 0145 0205 0275 0315 0375 0405 0435 0555 XXXX (1) (2) (3) (4) (5)

Description Resistance Thermometer, Pt 100, Class B Standard, suitable for Transmitter Mounting Connection Head Material IP Rating (1) Conduit Connection Thread Rosemount, Aluminum 68 M20 x 1.5 (cable entry) Rosemount, Aluminum 68 ½-inch NPT (cable entry) Rosemount, Stainless Steel 68 M20 x 1.5 (cable entry) Rosemount, Stainless Steel 68 ½-inch NPT (cable entry) GR-A/BL (BUZ), Aluminum 65 M20 x 1.5 TZ-A/BL (BUZH), Aluminum 65 M20 x 1.5 BUKH, Polyamide, Black 65 M20 x 1.5 GN-BL, Aluminum 54 M20 x 1.5 Rosemount, Aluminum with LCD Meter Cover 68 M20 x 1.5 (cable entry) Rosemount, Aluminum with LCD Meter Cover 68 ½-inch NPT (cable entry) Rosemount, Stainless Steel with LCD Meter Cover 68 M20 x 1.5 (cable entry) Rosemount, Stainless Steel with LCD Meter Cover 68 ½-inch NPT (cable entry) (Use for ordering sensor alone or sensor lead wire termination code 3) No Connection Head Sensor Lead Wire Termination Flying Leads – No Springs on DIN plate (For use with models 644 or 244E Rev. 5 or later, and model 144) Flying Leads – Springs on DIN plate (For use with models 644 or 244E Rev. 4 or earlier) Terminal Block – DIN 43762 Spring-Loaded Adapter – ½-inch NPT (For use with connection head option code N) Sensor Type Temperature Range [°C] (5) Single Element -50 to 450 Dual Element -50 to 450 Single Element -196 to 600 Dual Element -196 to 600 Extension Type Head Connection Instrument Connection Material DIN Standard M24 x 1.5 M24 x 1.5 Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 ½-inch BSPT (R ½-inch) Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 ½-inch BSPF (G ½) Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 ½-inch NPT Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 M20 x 1.5 Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 M18 x 1,5 Stainless Steel (min. length N = 35 mm) Nippel-Union-Nipple ½-inch NPT ½-inch NPT Stainless Steel (min. length N = 110 mm) Nippel-Union (No head) ½-inch NPT Stainless Steel (min. length N = 80 mm) No Extension (Stand-alone sensor, available only with extension length (N) code 0000) No Extension, Head Connection ½-inch NPT (Sensor & head assembly, available only with extension length (N) code 0000) No Extension, Head Connection M24 x 1.5 (Sensor & head assembly, available only with extension length (N) code 0000) No Extension, with Sealing Screw M24 x 1.5 (Sensor & head assembly, available only with extension length (N) code 0000) Extension Length (N) in Millimeters No Extension (For use with extension codes N, L, W, and V) 80 (Standard for extension type code J) 110 (Standard for extension type codes F and J) 135 (Standard for DIN extension used with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) 149 (Standard for DIN extension used with Form B connection head material codes J, L, T, and U) Non-Standard Extension Length Thermowell Material No Thermowell Sensor Length (L) in Millimeters 145 205 275 315 375 405 435 555 Non-Standard Sensor Length

To maintain IP 68 rating, you must use a suitable cable gland on the conduit connection thread, and all threads must be sealed wit a suitable sealing tape. Connection heads suitable for mounting a transmitter inside (Model 144, 244, and 644). Connection head suitable for mounting a transmitter inside (Model 144). For use with connection head code N and extension type codes J or N. Temperature range valid for tolerance Class B only.

13

Sensors and Assemblies

Model

Sensors and Assemblies

Series 65 Platinum RTD WITHOUT Thermowell (Part 2 of 2) Code A1 A2 A3 (6) A4 (6)

Sensors and Assemblies

Additional Options Single Element Class A Sensor from -50 to +450 °C Dual Element Class A Sensor from -50 to +450 °C Single Element Class 1/3 DIN B Sensor from 0 to 100 °C Dual Element Class 1/3 DIN B Sensor from 0 to 100 °C Approval Options ED (7) EEx d CENELEC/KEMA Flameproof Approval (for use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) E9 (8) EEx d CENELEC/ISSeP Flameproof Approval (for use with sensor lead wire termination code 3) N1 (9) EEx n BASEEFA Non-Incendive Approval (for use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) Accessory Options G1 External Ground Screw (only for use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) G2 Cable Gland for Cable Ø 6.5 - 13.9 mm; selection, see page 62 (only for use with Rosemount connection head material codes C, G, 1, 3) G3 Cover Chain (only available with Rosemount connection head material codes C, D, G, H) G6 Aluminum Extension Ring for Dual Transmitter Mounting in Connection Head (only for use with Rosemount connection head material codes C and D) M01 Ex i Temperature Sensor acc. to EN 50014 and EN 50020 with manufacturer declaration for (Ex i) use in Zone 1 M02 Sensor Ø 8 mm with Welded-on Sleeve M10–M17 Compression Fittings, see page 65 (not for use with option code M02) M99 Order Specific Drawing Mounting Options X1 Sensor Assembled to Specific Temperature Transmitter – hand tight, PTFE tape, fully wired (valid for Rosemount transmitter models 144H, 244EH, 644H, 3144, and 3244MV) Note: Specify the same option on the transmitter model number, if you order X1 with a transmitter. Calibration Options V10 Works Certificate – sensor calibration from -50 to 450 °C with A, B, C, and Callendar van Dusen constants V11 Works Certificate – sensor calibration from 0 to 100 °C with A, B, C, and Callendar van Dusen constants V13 Works Certificate – sensor calibration from 0 to 600 °C with A, B, C, and Callendar van Dusen constants V15 Works Certificate – sensor calibration from -196 to 600 °C with A, B, C, and Callendar van Dusen constants V16 Works Certificate – sensor calibration from -50 to 100 °C with A, B, C, and Callendar van Dusen constants X8 Works Certificate – sensor calibration over specified temperature range with A, B, C, and Callendar van Dusen constants X9 Works Certificate – sensor calibration for one customer specified temperature point K1 DKD Certificate – sensor calibration at a single specified temperature point K2 DKD Certificate – sensor calibration at two specified temperature points K3 DKD Certificate – sensor calibration at three specified temperature points K4 DKD Certificate – sensor calibration at four specified temperature points K5 DKD Certificate – sensor calibration at five specified temperature points KS1 DKD Certificate for transmitter and sensor combination at a single specified temperature point (10) KS2 DKD Certificate for transmitter and sensor combination at two specified temperature points (10) KS3 DKD Certificate for transmitter and sensor combination at three specified temperature points (10) KS4 DKD Certificate for transmitter and sensor combination at four specified temperature points (10) KS5 DKD Certificate for transmitter and sensor combination at five specified temperature points (10) WS1 Works Certificate for transmitter and sensor combination at a single specified temperature point (10) WS2 Works Certificate for transmitter and sensor combination at two specified temperature points (10) WS3 Works Certificate for transmitter and sensor combination at three specified temperature points (10) WS4 Works Certificate for transmitter and sensor combination at four specified temperature points (10) WS5 Works Certificate for transmitter and sensor combination at five specified temperature points (10) Other Options: • Other cable entries • Other tests (6)

Special tolerances available on request. For use with sensor lead wire termination code 2 or 0, if a Rosemount transmitter is being mounted directly on the DIN plate (see Section 5). (8) The ½-inch NPT spring-loaded adapter sensor with the E9 approval requires sensor lead wire termination code 3, and can only be supplied assembled to a Rosemount model 3144 or 3244MV smart temperature transmitter. (9) For complete assemblies or as replacement sensors for type N-series, component parts are not approved. If transmitter is mounted in the connection head, the sensor lead wire termination code 0 – flying leads – is requested. (10) Requires simultaneous use of mounting option code X1. (7)

Ordering Example Typical Model-No.:

14

Model

Connection Head

Sensor Lead Wire Termination

Sensor Type

Extension Type

Extension Length

Thermowell Material

Sensor Length

Additional Options

0065

C

2

3

D

0149

N

0315

A1

Sensors and Assemblies

SERIES 65 PLATINUM RTD 95 TUBULAR THERMOWELL

WITH

SERIES

Sensors and Assemblies

Series 65 RTDs with tubular thermowells are used primarily to measure temperatures in the operating range up to 600 °C, at moderate pressure up to 40 bar and moderate flow velocity up to 40 m/s in fluid and gaseous media in vessels and pipelines. The low chemical aggressivity allows the use of NiCr steel t-wells as standard. This design consists of an exchangable mineral insulated sensor which is fitted into a housing with connection head and welded thermowell Form 2G, 2F, 3G, and 3F acc. to DIN 43772. A thermowell variant is the design without extension (Type GN) which allows short immersion lengths up to 50 mm. The tapered thermowell design satisfies the standards laid down by DIN and the German Standard Committee of Measurement and Control Technology of the Chemicals Industry (NAMUR). This tapered design shortens the response time. The material for all tubular thermowell-designs is 316 Ti (1.4571).

Applications • • • • •

HSG_007BW.tif

This assembly with welded tubular thermowell can be combined from standardized components. The immersion lengths can be selected individually. The minimum and maximum immersion lengths can be obtained from Table 2. The length indication for each thermowell design given in Table 2 aims at the selection of standard sensor lengths according to DIN 43772.

Figure 10: Sensors with Tubular Thermowell.

General machinery and apparatus engineering Chemical process engineering Petroleum/natural gas supply and processing Power generation and heat distribution Food and beverage industries

The mechanical and thermal loading of thermowells depends on the medium to be measured, its temperature and flow rate as well as on the construction material, thermowell design and the immersion length.

The given standard values are valid for water, air or vapor, and vertical pressure under the assumption of proper design and careful manufacture. Media with other densities result in other ratings.

15

Sensors and Assemblies

Table 2:

Standard Length Combination: Series 65 RTD and Series 185 Thermocouple Assemblies with Tubular Thermowell.

Code Z - NAMUR (Dimension)

Sensors and Assemblies

L U U N U N

- Range - Standard - Standard - Standard - Standard

Tubular, stepped - Type 3G and 3F acc. to DIN 43772 (NAMUR), 12 x 2.5 mm tapered to 9 mm 110 - 130

with thread (1) with type DIN A/B conn. head with flange with type DIN A/B conn. head

Code Y - Type GN 9 (Dimension)

275 160 - 240 130 105 / 120 185 50 / 65

315 200 - 300 160 115 / 130 225 50 / 65

375 280 - 360 220 115 / 130 285 50 / 65

435 360 - 480 280 115 / 130 345 50 / 65

555 400 115 / 130 465 50 / 65

Tubular, without Extension, straight - previous Type GN, 9 x 1 mm

L U - Standard with thread

145 100

Code Y - Type GN 11 (Dimension)

205 160

275 230

405 360

555 510

Tubular, without Extension, straight - previous Type GN, 11 x 1 mm or 11 x 2 mm

L U - Standard with thread

145 100

205 160

275 230

405 360

555 510

Code Z - Type GB 9 (Dimension)

Tubular, straight - Type 2G acc. to DIN 43772 (previous Type GB), 9 x 1 mm

L U - Range U - Standard with thread

165 45 - 90

Code Z - Type GC 11 (Dimension)

Tubular, straight - Type 2G acc. to DIN 43772 (previous Type GC), 11 x 2 mm

L U - Range U - Standard with thread N - Standard with type DIN A/B conn. head

165 45 - 90

Code Z - Type (Dimension)

Tubular, straight - Type 2F acc: to DIN 43772 (previous Type FC), 11 x 2 mm

L U - Range U - Standard with flange N - Standard with type DIN A/B conn. head (1)

205 130 - 200 115 50 / 65 115 50 / 65

205 50 - 130

275 100 - 200

205 50 - 130

275 100 - 200

205 115 - 130

275 100 - 200

315 150 - 240 160

340 150 - 265 160 140 / 155

315 150 - 240 160 115 / 130

375 200 - 300

375 200 - 300

375 200 - 300

405 240 - 330 250

555 300 - 480 400

430 240 - 355 250 140 / 155

580 300 - 505 400 140 / 155

405 240 - 330 250 115 / 130

555 300 - 480 400 115 / 130

Min. length for tapered thread is: L - Uk = 95 mm. If it is less than 95 mm, choose the next Standard Sensor Length.

Table 3: Type

Loadings of Thermowells. Dimensions

Process Connection

Material

Max. Flow Velocity [m/s] Air

Water

Immersion Length [mm]

Max. Pressure [bar] (1)

At Temperature [°C]

0

100

200

300

400

GN, GB

9 x 1 mm 1.4571 (316 Ti)

Screw Socket G ½

25

3

160 250 400

50 40 18

48 40 18

44 40 18

40 40 18

36 36 18

GN, GC FC

11 x 2 mm 1.4571 (316 Ti)

Screw Socket G 1

40

5

160 250 400

100 50 18

95 50 18

92 50 18

88 50 18

80 50 18

NAMUR

12 x 2.5 mm 1.4571 (316 Ti)

Screw Socket G 1

40

5

160 220 280

100 100 100

100 100 100

100 100 100

100 78 55

100 78 55

(1)

16

For immersion length [mm]

Sensors and Assemblies

Figure 11: Series 65 RTD and Series 185 Thermocouple Assemblies with Tubular Thermowell – Dimensional Drawing. Connection Heads Model: Rosemount Model: BUKH Aluminum, Stainless Steel Polyamide Codes C, D, G, H, 1, 2, 3, 4 Code T

Model: TZ-A/BL Aluminum Code L

Sensors and Assemblies

Sensor Design

Mounting Example

Model: GR-A/BL Aluminum Code J

Model: GN-BL Aluminum Code U

Sensor Lead Wire Terminations, see Figure 7

Extensions and Options Welded-on Threaded Connections Parallel (G, M) Tapered (R, NPT) Code Z Code Z

Welded-on Flange Code Z

No Extension Type GN Code Y

Thermowells

L

= Sensor Length

N = Extension Length N K = Extension Length (tapered) NZ = Extension Length (parallel)

U = Immersion Length U K = Immersion Length (tapered) UZ = Immersion Length (parallel)

D

= Thermowell Outer Diameter Dimensions in millimeters

17

25_3b_abb11.tif

Forms GN, 2G(GB, GC), Forms 3G, 3F (NAMUR), 2F(FC), DIN 43772, straight DIN 43772, stepped Codes G50 - G97, H30 - H38 Codes G02-G42, L02-L32, H02-H26

Sensors and Assemblies

Ordering Information: Series 65 Platinum RTD WITH Series 95 Tubular Thermowell (Part 1 of 4) Model

Sensors and Assemblies

0065 Code C(2) D(2) G(2) H(2) J(2) L(2) T(2) U(3) 1 2 3 4 Code 0 1 2 Code 1 2 3 4 Code Y Z Code 0000 0050 0065 0105 0115 0120 0130 0140 0155 XXXX Code Y Code 0050 0075 0100 0115 0130 0160 0185 0220 0225 0230 0250 0280 0285 0345 0360 0400 0465 0510 XXXX

18

Description Resistance Thermometer, Pt 100, Class B, suitable for Transmitter Mounting Connection Head Material IP Rating (1) Conduit Connection Thread Rosemount, Aluminum 68 M20 x 1.5 (cable entry) Rosemount, Aluminum 68 ½-inch NPT (cable entry) Rosemount, Stainless Steel 68 M20 x 1.5 (cable entry) Rosemount, Stainless Steel 68 ½-inch NPT (cable entry) GR-A/BL (BUZ), Aluminum 65 M20 x 1.5 TZ-A/BL (BUZH), Aluminum 65 M20 x 1.5 BUKH, Polyamide, Black 65 M20 x 1.5 GN-BL, Aluminum 54 M20 x 1.5 Rosemount, Aluminum with LCD Meter Cover 68 M20 x 1.5 (cable entry) Rosemount, Aluminum with LCD Meter Cover 68 ½-inch NPT (cable entry) Rosemount, Stainless Steel with LCD Meter Cover 68 M20 x 1.5 (cable entry) Rosemount, Stainless Steel with LCD Meter Cover 68 ½-inch NPT (cable entry) Sensor Lead Wire Termination Flying Leads – No Springs on DIN plate (For use with models 644, 244E Rev. 5 or later, and model 144) Flying Leads – Springs on DIN plate (For use with models 644, 244E Rev. 4 or earlier) Terminal Block – DIN 43762 Sensor Type Temperature Range [°C] (4) Single Element -50 to 450 Dual Element -50 to 450 Single Element -196 to 600 Dual Element -196 to 600 Extension Type Tubular – No Extension (Previous form GN) Tubular – With Extension (Previous form GB, GC, FC, NAMUR) Extension Length (N) in Millimeters (For use with extension code Y) No Extension 50 Note: Standard extension length depends on thermowell design, 65 see Table 2 on page 16. 105 115 120 130 140 155 Non-Standard Extension Length Note: Non-standard lengths are available from 50 to 990 mm. Thermowell Material Max. Temparature Range AISI 316Ti (1.4571) Note: Loadings, see Table 3 on page 16. Immersion Length (U k,Uz,U) in Millimeters Note: Standard immersion length depends on thermowell design, 50 75 see Table 2 on page 16. 100 115 130 160 185 220 225 230 250 280 285 345 360 400 465 510 Non-Standard Immersion Length Note: Non-standard lengths are available from 50 to 2500 mm.

Sensors and Assemblies

Series 65 Platinum RTD WITH Series 95 Tubular Thermowell (Part 2 of 4)

(1) (2) (3) (4)

Mounting Type Thread, tapered Thread, tapered Thread, tapered Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, tapered Thread, tapered Thread, tapered Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Thread, parallel Flange, RF Flange, RF Flange, RF Flange, RF Flange, RF Flange, RF

Process Connection ½-inch BSPT (R ½-inch) ¾-inch BSPT (R ¾-inch) 1-inch BSPT (R 1-inch) ½-inch BSPF (G ½) ¾-inch BSPF (G ¾) 1-inch BSPF (G 1) M20 x 1.5 ½-inch NPT ¾-inch NPT 1-inch NPT 3/ -inch BSPF (G 3/8) 8 ½-inch BSPF (G ½) ¾-inch BSPF (G ¾) 1-inch BSPF (G 1) M18 x 1.5 M20 x 1.5 3/ -inch BSPF (G 3/8) 8 ½-inch BSPF (G ½) ¾-inch BSPF (G ¾) 1-inch BSPF (G 1) M18 x 1.5 M20 x 1.5 3/ -inch BSPF (G 3/8) 8 ½-inch BSPF (G ½) ¾-inch BSPF (G ¾) 1-inch BSPF (G 1) M18 x 1.5 M20 x 1.5 3/ -inch BSPF (G 3/8) 8 ½-inch BSPF (G ½) ¾-inch BSPF (G ¾) 1-inch BSPF (G 1) M18 x 1.5 M20 x 1.5 3/ -inch BSPF (G 3/8) 8 ½-inch BSPF (G ½) ¾-inch BSPF (G ¾) 1-inch BSPF (G 1) M18 x 1.5 M20 x 1.5 3/ -inch BSPF (G 3/8) 8 ½-inch BSPF (G ½) ¾-inch BSPF (G ¾) 1-inch BSPF (G 1) M18 x 1.5 M20 x 1.5 1-inch 150 lbs. 1.5-inch 150 lbs. 2-inch 150 lbs. 1-inch 300 lbs. 1.5-inch 300 lbs. 2-inch 300 lbs.

Stem Style Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Straight, GN, D. 9 x 1 mm Straight, GN, D. 9 x 1 mm Straight, GN, D. 9 x 1 mm Straight, GN, D. 9 x 1 mm Straight, GN, D. 9 x 1 mm Straight, GN, D. 9 x 1 mm Straight, GN, D. 11 x 1 mm Straight, GN, D. 11 x 1 mm Straight, GN, D. 11 x 1 mm Straight, GN, D. 11 x 1 mm Straight, GN, D. 11 x 1 mm Straight, GN, D. 11 x 1 mm Straight, GN, D. 11 x 2 mm Straight, GN, D. 11 x 2 mm Straight, GN, D. 11 x 2 mm Straight, GN, D. 11 x 2 mm Straight, GN, D. 11 x 2 mm Straight, GN, D. 11 x 2 mm Straight, GB, D. 9 x 1 mm Straight, GB, D. 9 x 1 mm Straight, GB, D. 9 x 1 mm Straight, GB, D. 9 x 1 mm Straight, GB, D. 9 x 1 mm Straight, GB, D. 9 x 1 mm Straight, GB, D. 11 x 1 mm Straight, GB, D. 11 x 1 mm Straight, GB, D. 11 x 1 mm Straight, GB, D. 11 x 1 mm Straight, GB, D. 11 x 1 mm Straight, GB, D. 11 x 1 mm Straight, GC, D. 11 x 2 mm Straight, GC, D. 11 x 2 mm Straight, GC, D. 11 x 2 mm Straight, GC, D. 11 x 2 mm Straight, GC, D. 11 x 2 mm Straight, GC, D. 11 x 2 mm Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR Stepped, NAMUR

Sensors and Assemblies

Code G02 G04 G06 G20 G22 G24 G91 G38 G40 G42 G50 G52 G54 G56 G58 G92 G60 (5) G62(5) G64(5) G66(5) G68(5) G93(5) G61 G63 G65 G67 G69 G94 G70 G72 G74 G76 G78 G95 G80 (5) G82 (5) G84(5) G86(5) G88(5) G96(5) G81 G83 G85 G87 G89 G97 L02 L08 L14 L20 L26 L32

IP 68 rating requires a suitable cable gland on the conduit connection thread. All threads must be sealed. Connection head suitable for mounting a transmitter (model 144, 244, and 644). Connection head suitable for mounting a transmitter (model 144). Temperature range valid for tolerance Class B only.

19

Sensors and Assemblies

Series 65 Platinum RTD WITH Series 95 Tubular Thermowell (Part 3 of 4)

Sensors and Assemblies

Code H02 H08 H14 H20 H26 H30 H32 H34 H36 H38 Code A1 A2 A3(6) A4(6) ED(7) N1(8) G1 G2 G3 G6 M01 M02 M99 Q8 R01 R03 R04 R16 R18 R19 X1

V10 V11 V13 V15 V16 X8 X9 K1 K2 K3 K4 K5

20

Mounting Type Process Connection Stem Style Flange, Form C DN 25 PN 16 Stepped, NAMUR Flange, Form C DN 25 PN 25/40 Stepped, NAMUR Flange, Form C DN 40 PN 16 Stepped, NAMUR Flange, Form C DN 40 PN 25/40 Stepped, NAMUR Flange, Form C DN 50 PN 40 Stepped, NAMUR Flange, Form C DN 25 PN 16 Straight, FC, D. 11 x 2 mm Flange, Form C DN 25 PN 25/40 Straight, FC, D. 11 x 2 mm Flange, Form C DN 40 PN 16 Straight, FC, D. 11 x 2 mm Flange, Form C DN 40 PN 25/40 Straight, FC, D. 11 x 2 mm Flange, Form C DN 50 PN 40 Straight, FC, D. 11 x 2 mm Additional Options Sensor Options Single Element Class A Sensor from -50 °C to +450 °C Dual Element Class A Sensor from -50 °C to +450 °C Single Element Class 1/3 DIN B Sensor from 0 °C to 100 °C Dual Element Class 1/3 DIN B Sensor from 0 °C to 100 °C Approval Options EEx d CENELEC/KEMA Flameproof Approval (for use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) EEx n BASEEFA Non-Incendive Approval (for use with Rosemount 644 connection head material codes C, D, G, H, 1, 2, 3, 4) Accessory Options External Ground Screw (only for use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) Cable Gland for Cable Ø 6.5 - 13.9 mm; selection, see page 62 (only for use with Rosemount connection head material codes C, G, 1, 3) Cover Chain (only available with Rosemount connection head material codes C, D, G, and H) Aluminum Extension Ring for Dual Transmitter Mounting in Connection Head (only for use with Rosemount connection head material codes C and D) Ex i Temperature Sensor acc. to EN 50014 and EN 50020 with manufacturer declaration for (Ex i) use in Zone 1 Sensor Ø 8 mm with Welded-on Sleeve Order Specific Drawing Thermowell Options Thermowell Material Certificate, DIN EN 10204 3.1B Thermowell Pressure Testing Thermowell Dye Penetration Testing Thermowell Special Cleaning Ring t Flange Face to ANSI B 16.5, codes LXX Flange with Groove acc. to DIN 2512 (Form N), codes HXX Flange with Tongue acc. to DIN 2512 (Form F), codes HXX Mounting Options Sensor Assembled to a Specific Temperature Transmitter – hand tight, PTFE tape, fully wired (valid for Rosemount transmitter model 144H, 244EH, 644H, 3144, and 3244MV) Note: Specify the same option on the transmitter model number, if you order X1 with a transmitter. Calibration Options Works Certificate – sensor calibration from -50 to 450 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from 0 to 100 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from 0 to 600 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from -196 to 600 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from -50 to 100 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration over specified temperature range with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration for one customer specified temperature point DKD Certificate – sensor calibration at a single specified temperature point DKD Certificate – sensor calibration at two specified temperature points DKD Certificate – sensor calibration at three specified temperature points DKD Certificate – sensor calibration at four specified temperature points DKD Certificate – sensor calibration at five specified temperature points

Sensors and Assemblies

Series 65 Platinum RTD WITH Series 95 Tubular Thermowell (Part 4 of 4) KS1 KS2 KS3 KS4 KS5 WS1 WS2 WS3 WS4 WS5

(5) (6) (7) (8)

(9)

Additional Options Calibration Options DKD Certificate for transmitter and sensor combination at a single specified temperature point (9) DKD Certificate for transmitter and sensor combination at two specified temperature points (9) DKD Certificate for transmitter and sensor combination at three specified temperature points (9) DKD Certificate for transmitter and sensor combination at four specified temperature points (9) DKD Certificate for transmitter and sensor combination at five specified temperature points (9) Works Certificate for transmitter and sensor combination at a single specified temperature point (9) Works Certificate for transmitter and sensor combination at two specified temperature points (9) Works Certificate for transmitter and sensor combination at three specified temperature points (9) Works Certificate for transmitter and sensor combination at four specified temperature points (9) Works Certificate for transmitter and sensor combination at five specified temperature points (9) Other Options: • Other cable entries • Other tests • Other process connections

Sensors and Assemblies

Code

This stem style requires 8 mm sensors and is only valid with option code M02. Special tolerances available on request. For use with sensor lead wire termination code 2 or 0, if a Rosemount transmitter is being mounted directly on the DIN plate (see Section 5). For complete assemblies or as replacement sensors for type N-series. Component parts are not approved. If transmitter is mounted in the connection head, the sensor lead wire termination code 0 – flying leads – is requested. Requires simultaneous use of mounting option code X1.

Ordering Example Model Typical Model-No.:

0065

Connection Sensor Lead Sensor Head Wire Termination Type L

2

1

Extension Type

Extension Length

Z

0115

Thermowell Immersion Material Length Y

0375

Mounting Type

Additional Options

G20

X1

21

Sensors and Assemblies

SERIES 65 PLATINUM RTD WITH WELD-IN BARSTOCK THERMOWELL

This design consists of a mineral insulated measuring insert, connection head, DIN extension and weld-in barstock thermowell Form 4 acc. to DIN 43772 (former DIN 43763 Form D) with an outer diameter of 24 mm. The design of the thermowell allows it to be optimized to meet the measurement and mechanical requirements, thus enabling it to withstand high levels of stress caused by pressure, flow and vibration. Four thermowell materials are offered as standard to meet the requirements of the steam vessel and pressure container regulation, see Ordering Information on page 24.

Applications • Power generation and heat distribution • Chemical process engineering

HSG_004BW.tif

Sensors and Assemblies

Series 65 RTD’s with weld-in thermowells are used primarily to measure temperatures of gas, water, or vapor in hot steam and high pressure process plants with corrosive media in pipes in the operating temperature range from 400 up to 570 °C and at 600 bar.

Figure 12: Thermometer with Weld-in Thermowell.

22

Sensors and Assemblies

Figure 13: Series 65 RTD and Series 185 Thermocouple Assemblies with Weld-in Thermowell – Dimensional Drawing. Sensor Design

Connection Heads Model: Rosemount Model: BUKH Aluminum, Stainless Steel Polyamide Codes C, D, G, H, 1, 2, 3, 4 Code T

Model: TZ-A/BL Aluminum Code L

Model: GR-A/BL Aluminum Code J

Sensors and Assemblies

Mounting Example

Model: GN-BL Aluminum Code U

Sensor Lead Wire Terminations, see Figure 7

Extensions Welded-on Thread Connection, parallel – M18 x 1.5 Code T

Thermowells

L

= Sensor Length

N U R

= Extension Length = Immersion Length = Lagging Length Dimensions in millimeters

23

25_3b_abb13.tif

Form 4, DIN 43772 (Form D Thermowell) Codes E01 - E05

Sensors and Assemblies

Ordering Information: Series 65 Platinum RTD WITH Series 96 Weld-in Barstock Thermowell (Part 1 of 2) Model

Sensors and Assemblies

0065 Code C(2) D(2) G(2) H(2) J(2) L(2) T(2) U(3) 1 2 3 4 Code 0 1 2 Code 1 2 3 4 Code T Code 0135 0149 XXXX Code K P Y Z Code 0065 0125 Code E01 E02 E04 E05 Code A1 A2 A3(5) A4(5) ED(6) N1 (7) (1) (2) (3) (4) (5) (6) (7)

Description Resistance Thermometer, Pt 100, Class B, suitable for Transmitter Mounting Connection Head IP Rating (1) Conduit Connection Thread Rosemount, Aluminum 68 M20 x 1.5 (cable entry) Rosemount, Aluminum 68 ½-inch NPT (cable entry) Rosemount, Stainless Steel 68 M20 x 1.5 (cable entry) Rosemount, Stainless Steel 68 ½-inch NPT (cable entry) GR-A/BL (BUZ), Aluminum 65 M20 x 1.5 TZ-A/BL (BUZH), Aluminum 65 M20 x 1.5 BUKH, Polyamide, Black 65 M20 x 1.5 GN-BL, Aluminum 54 M20 x 1.5 Rosemount, Aluminum with LCD Meter Cover 68 M20 x 1.5 (cable entry) Rosemount, Aluminum with LCD Meter Cover 68 ½-inch NPT (cable entry) Rosemount, Stainless Steel with LCD Meter Cover 68 M20 x 1.5 (cable entry) Rosemount, Stainless Steel with LCD Meter Cover 68 ½-inch NPT (cable entry) Sensor Lead Wire Termination Flying Leads – No Springs on DIN plate (For use with models 644, 244E Rev. 5 or later, and model 144) Flying Leads – Springs on DIN plate (For use with models 644, 244E Rev. 4 or earlier) Terminal Block – DIN 43762 Sensor Type Temperature Range [°C] (4) Single Element -50 to 450 Dual Element -50 to 450 Single Element -196 to 600 Dual Element -196 to 600 Extension Type Instrument Connection Material DIN Standard M18 x 1.5 Stainless Steel (min. length = 35 mm) Extension Length (N) in Millimeters 135 (For use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) 149 (For use with Form B connection head codes J, L, T, and U) Non-Standard Extension Length Thermowell Material Temperature Range [°C] AISI A 204 Size A (1.5415) 520 AISI 182-F22 (1.7380) 570 AISI 316Ti (1.4571) 400 AISI A 182-F11 (1.7335) 570 Immersion Length (U) in Millimeters 65 (For use with mounting type codes E01, and E04) 125 (For use with mounting type codes E02, and E05) Mounting Type Process Connection Stem Style D1, welded 24h7 Tapered D2, welded 24h7 Tapered D4, welded 24h7 Tapered D5, welded 24h7 Tapered Additional Options Sensor Options Single Element Class A Sensor from -50 to +450 °C Dual Element Class A Sensor from -50 to +450 °C Single Element Class 1/3 DIN B Sensor from 0 to 100 °C Dual Element Class 1/3 DIN B Sensor from 0 to 100 °C Approval Options EEx d CENELEC/KEMA Flameproof Approval (for use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) EEx n BASEEFA Non-Incendive Approval (for use with Rosemount 644 connection head material codes C, D, G, H, 1, 2, 3, 4)

IP 68 rating requires a suitable cable gland on the conduit connection thread. All threads must be sealed. Connection head suitable for mounting a transmitter (model 144, 244, and 644). Connection head suitable for mounting a transmitter (model 144). Temperature range valid for tolerance class B only. Special tolerances available on request. For use with sensor lead wire termination code 2 or 0, if a Rosemount transmitter is being mounted directly on the DIN plate, see Section 5. For complete series or as replacement sensors for type N-series. Component parts are not approved. If transmitter is mounted in the connection head, the sensor lead wire termination code 0 - flying leads - is requested.

24

Sensors and Assemblies

G1 G2 G3 G6 M01 M99 Q8 R01 R03 R04 R21 X1

V10 V11 V13 V15 V16 X8 X9 K1 K2 K3 K4 K5 KS1 KS2 KS3 KS4 KS5 WS1 WS2 WS3 WS4 WS5

(8)

Accessory Options External Ground Screw (only for use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) Cable Gland for Cable Ø 6.5 - 13.9 mm; selection, see page 62 (only for use with Rosemount connection head material codes C, G, 1, 3) Cover Chain (only available with Rosemount connection head material codes C, D, G, and H) Aluminum Extension Ring for Dual Transmitter Mounting in Connection Head (only for use with Rosemount connection head material codes C and D) Ex i Temperature Sensor acc. to EN 50014 and EN 50020 with manufacturer declaration for (Ex i) use in Zone 1 Order Specific Drawing Thermowell Options Thermowell Material Certificate, DIN EN 10204 3.1B Thermowell Pressure Testing Thermowell Dye Penetration Testing Thermowell Special Cleaning Wake Frequency – Thermowell Strength Calculation Mounting Options Sensor Assembled to a Specific Temperature Transmitter – hand tight, PTFE tape, fully wired (valid for Rosemount transmitter model 144H, 244EH, 644H, 3144, and 3244MV) Note: Specify the same option on the transmitter model number, if you order X1 with a transmitter. Calibration Options Works Certificate – sensor calibration from -50 to 450 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from 0 to 100 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from 0 to 600 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from -196 to 600 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from -50 to 100 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration over specified temperature range with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration for one customer specified temperature point DKD Certificate – sensor calibration at a single specified temperature point DKD Certificate – sensor calibration at two specified temperature points DKD Certificate – sensor calibration at three specified temperature points DKD Certificate – sensor calibration at four specified temperature points DKD Certificate – sensor calibration at five specified temperature points DKD Certificate for transmitter and sensor combination at a single specified temperature point (8) DKD Certificate for transmitter and sensor combination at two specified temperature points (8) DKD Certificate for transmitter and sensor combination at three specified temperature points (8) DKD Certificate for transmitter and sensor combination at four specified temperature points (8) DKD Certificate for transmitter and sensor combination at five specified temperature points (8) Works Certificate for transmitter and sensor combination at a single specified temperature point (8) Works Certificate for transmitter and sensor combination at two specified temperature points (8) Works Certificate for transmitter and sensor combination at three specified temperature points (8) Works Certificate for transmitter and sensor combination at four specified temperature points (8) Works Certificate for transmitter and sensor combination at five specified temperature points (8) Other Options: • Other cable entries • Other tests • Other process connections

Requires simultaneous use of mounting option code X1.

Ordering Example Model Typical Model-No.:

0065

Connection Sensor Lead Head Wire Term. J

0

Sensor Type

Extension Type

Extension Length

3

T

0149

Thermowell Immersion Material Length Z

0125

Mounting Type

Additional Options

E02

Q8, X1

25

Sensors and Assemblies

Series 65 Platinum RTD WITH Series 96 Weld-in Barstock Thermowell (Part 2 of 2)

Sensors and Assemblies

SERIES 65 PLATINUM RTD WITH THREADED BARSTOCK THERMOWELL

Applications • Power generation and heat distribution • Chemical process engineering

HSG_005BW.tif

Sensors and Assemblies

The mineral insulated sensor is installed in a threounted thermowell similar to Form 6 and 7 acc. to DIN 43772. The outer diameter of the tapered barstock thermowell depends on the type and size of the process connection thread (see Figures 41, 42). The design of the thermowell allows it to be optimized to meet measurement and mechanical requirements, thus enabling it to withstand high levels of stress caused by pressure, flow and vibration. Two standard thermowell materials – 316L (1.4404) and 316Ti (1.4571) – are available.

Figure 14: Thermometer with Threaded Barstock Thermowell.

26

Sensors and Assemblies

Figure 15: Series 65 RTD and Series 185 Thermocouple Assemblies with Threaded Barstock Thermowell – Dimensional Drawing. Sensor Design

Connection Heads Model: TZ-A/BL Aluminum Code L

Sensors and Assemblies

Model: Rosemount Model: BUKH Aluminum, Stainless Steel Polyamide Codes C, D, G, H, 1, 2, 3, 4 Code T

Mounting Example

Model: GR-A/BL Aluminum Code J

Model: GN-BL Aluminum Code U

Sensor Lead Wire Terminations, see Figure 7

Extensions and Options Welded-on Threaded Connections Parallel (G, M) Tapered (R, NPT) Codes A, C, E, T Codes B, D

Nipple-Union Code J

Nipple-Union-Nipple Code F

Thermowells

L

= Sensor Length

N K = Extension Length (tapered) NZ = Extension Length (parallel)

U K = Immersion Length (tapered) UZ = Immersion Length (parallel) Dimensions in millimeters

27

25_3b_abb15.tif

Similar to Form 6, DIN 43772, Similar toForm 7, DIN 43772, Parallel Threaded Conn. Tapered Threaded Conn. Codes G26 - G30, G90, G98 Codes G08 - G12, G44 - G48

Sensors and Assemblies

Ordering Information: Series 65 Platinum RTD WITH Series 96 Threaded Barstock Thermowell (Part 1 of 3) Model

Sensors and Assemblies

0065 Code C(2) D(2) G(2) H(2) J(2) L(2) T(2) U(3) 1 2 3 4 N Code 0 1 2 3(4) Code 1 2 3 4 Code A B C D E T F J N Code 0000 0080 0110 0135 0149 XXXX Code D Y Code 0055 0075 0115 0155 0215 0335 0425 XXXX

28

Description Resistance Thermometer, Pt100, class B, suitable for Transmitter Mounting Connection Head Material IP Rating (1) Conduit Connection Thread Rosemount, Aluminum 68 M20 x 1.5 (cable entry) Rosemount, Aluminum 68 ½-inch NPT (cable entry) Rosemount, Stainless Steel 68 M20 x 1.5 (cable entry) Rosemount, Stainless Steel 68 ½-inch NPT (cable entry) GR-A/BL (BUZ), Aluminum 65 M20 x 1.5 TZ-A/BL (BUZH), Aluminum 65 M20 x 1.5 BUKH, Polyamide, Black 65 M20 x 1.5 GN-BL, Aluminum 54 M20 x 1.5 Rosemount, Aluminum with LCD Meter Cover 68 M20 x 1.5 (cable entry) Rosemount, Aluminum with LCD Meter Cover 68 ½-inch NPT (cable entry) Rosemount, Stainless Steel with LCD Meter Cover 68 M20 x 1.5 (cable entry) Rosemount, Stainless Steel with LCD Meter Cover 68 ½-inch NPT (cable entry) No Connection Head (For use with sensor lead wire termination code 3) Sensor Lead Wire Termination Flying Leads – No Springs on DIN plate (For use with models 644, 244E transmitters revision 5 or later and model 144) Flying Leads – Springs on DIN plate (For use with models 644, 244E transmitters revision 4 or earlier) Terminal Block – DIN 43762 Spring-Loaded Adapter – ½-inch NPT (For use with connection head option code N) Sensor Type Temperature Range [°C] (5) Single Elements -50 to 450 Dual Elements -50 to 450 Single Elements -196 to 600 Dual Elements -196 to 600 Extension Type Head Connection Instrument Connection Material DIN Standard M24 x 1.5 M24 x 1.5 Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 ½-inch BSPT (R ½-inch) Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 ½-inch BSPF (G ½) Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 ½-inch NPT Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 M20 x 1.5 Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 M18 x 1.5 Stainless Steel (min. length N = 35 mm) Nipple-Union-Nipple ½-inch NPT ½-inch NPT Stainless Steel (min. length N = 110 mm) Nippel-Union (No head) ½-inch NPT Stainless Steel (min. length N = 80 mm) No Extension (For use with extension length N code 0000 and sensor lead wire termination code 3) Extension Length (N) in Millimeters No Extension (For use with extension type code N) 80 (Standard for extension type code J) 110 (Standard for extension type code F and J) 135 (Standard for DIN extension used with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) 149 (Standard for DIN extension used with Form B connection head material codes J, L, T, and U) Non-Standard Extension Length Thermowell Material AISI 316L (1.4404) AISI 316Ti (1.4571) Immersion Length (Uk,Uz) in Millimeters 55 Note: Tapered t-well parts are available up to 400 mm. 75 115 155 215 335 425 Non-Standard Immersion Length Note: Non-standard lengths are available from 55 to 1000 mm.

Sensors and Assemblies

Code G08 G10 G12 G26 G28 G30 G44 G46 G48 G90 G98 Code A1 A2 A3(6) A4(6) ED(7) E9(8) N1(9) G1 G2 G3 G6 M01 M99 Q8 R01 R03 R04 R06 R21 X1

V10 V11 V13 V15 V16 X8 X9 (1) (2) (3) (4) (5) (6) (7) (8)

(9)

Mounting Style Process Connection Stem Style Thread, tapered ½-inch BSPT (R ½-inch) Tapered Thread, tapered ¾-inch BSPT (R ¾-inch) Tapered Thread, tapered 1-inch BSPT (R 1-inch) Tapered Thread, parallel ½-inch BSPF (G ½) Tapered Thread, parallel ¾-inch BSPF (G ¾) Tapered Thread, parallel 1-inch BSPF (G 1) Tapered Thread, tapered ½-inch NPT Tapered Thread, tapered ¾-inch NPT Tapered Thread, tapered 1-inch NPT Tapered Thread, parallel M24 x 1.5 Tapered Thread, parallel M20 x 1.5 Tapered Additional Options Sensor Options Single Element Class A Sensor from -50 to +450 °C Dual Element Class A Sensor from -50 to +450°C Single Element Class 1/3 DIN B Sensor from 0 to 100 °C Dual Element Class 1/3 DIN B Sensor from 0 to 100 °C Approval Options EEx d CENELEC/KEMA Flameproof Approval (for use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) EEx d CENELEC/ISSeP Flameproof Approval (for use with sensor lead wire termination code 3) EEx n BASEEFA Non-Incendive Approval (for use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) Accessory Options External Ground Screw (only for use with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) Cable Gland for Cable Ø 6.5 - 13.9 mm; selection, see page 62 (only for use with Rosemount connection head material codes C, G, 1, 3) Cover Chain (only available with Rosemount 644 connection head material codes C, D, G, and H) Aluminum Extension Ring for Dual Transmitter Mounting in Connection Head (only for use with Rosemount connection head material codes C and D) Ex i Temperature Sensor acc. to EN 50014 and EN 50020 with manufacturer declaration for (Ex i) use in Zone 1 Order Specific Drawing Thermowell Options Thermowell Material Certification, DIN EN 10204 3.1B Thermowell Pressure Testing Thermowell Dye Penetration Testing Thermowell Special Cleaning Stainless Steel Plug and Chain Wake Frequency – Thermowell Strength Calculation Mounting Options Sensor Assembled to a Specific Temperature Transmitter – hand tight, PTFE tape, fully wired (valid for Rosemount transmitter model 144H, 244EH, 644H, 3144, and 3244MV) Note: Specify the same option on the transmitter model number, if you order X1 with a transmitter. Calibration Options Works Certificate – sensor calibration from -50 to 450 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from 0 to 100 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from 0 to 600 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from -196 to 600 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration from -50 to 100 °C with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration over specified temperature range with A, B, C, and Callendar van Dusen constants Works Certificate – sensor calibration for one customer specified temperature point

IP 68 rating requires a suitable cable gland on the conduit connection thread. All threads must be sealed. Connection head suitable for mounting a transmitter (model 144, 244, and 644). Connection head suitable for mounting a transmitter (model 144). For use with connection head code N and extension type code J or N. Temperature range valid for tolerance class B only. Special tolerances available on request. For use with sensor lead wire termination code 2 or 0, if a Rosemount transmitter is being mounted directly on the DIN plate, see Section 5. The ½-inch NPT spring-loaded adapter sensor with the E9 approval requires sensor lead wire termination code 3, and can only be supplied assembled to a Rosemount model 3144 or 3244MV smart temperature transmitter. For complete series or as replacement sensors for type N-series. Component parts are not approved. If transmitter is mounted in the connection head, the sensor lead wire termination code 0 – flying leads – is requested.

29

Sensors and Assemblies

Series 65 Platinum RTD WITH Series 96 Threaded Barstock Thermowell (Part 2 of 3)

Sensors and Assemblies

Series 65 Platinum RTD WITH Series 96 Threaded Barstock Thermowell (Part 3 of 3)

Sensors and Assemblies

K1 K2 K3 K4 K5 KS1 KS2 KS3 KS4 KS5 WS1 WS2 WS3 WS4 WS5

(10)

DKD Certificate – sensor calibration at a single specified temperature point DKD Certificate – sensor calibration at two specified temperature points DKD Certificate – sensor calibration at three specified temperature points DKD Certificate – sensor calibration at four specified temperature points DKD Certificate – sensor calibration at five specified temperature points DKD Certificate for transmitter and sensor combination at a single specified temperature point (10) DKD Certificate for transmitter and sensor combination at two specified temperature points (10) DKD Certificate for transmitter and sensor combination at three specified temperature points (10) DKD Certificate for transmitter and sensor combination at four specified temperature points (10) DKD Certificate for transmitter and sensor combination at five specified temperature points (10) Works Certificate for transmitter and sensor combination at a single specified temperature point (10) Works Certificate for transmitter and sensor combination at two specified temperature points (10) Works Certificate for transmitter and sensor combination at three specified temperature points (10) Works Certificate for transmitter and sensor combination at four specified temperature points (10) Works Certificate for transmitter and sensor combination at five specified temperature points (10) Other Options: • Other cable entries • Other tests

Requires simultaneous use of mounting option code X1.

Ordering Example Model Typical Model-No.:

30

0065

Connection Sensor Lead Head Wire Term. D

0

Sensor Type

Extension Type

Extension Length

4

B

0135

Thermowell Immersion Material Length D

0215

Mounting Type

Additional Options

G26

X1

Sensors and Assemblies

SERIES 65 PLATINUM RTD WITH FLANGED BARSTOCK THERMOWELL

Sensors and Assemblies

The mineral insulated sensor is installed in a flangemounted thermowell. The flanges conform to ASME/ANSI B16.5 and DIN 2519. The outer diameter of the tapered barstock thermowell depends on the type and the size of the process connection thread (see Figure 43). The design of the thermowell allows it to be optimized to meet measurement and mechanical requirements, thus enabling it to withstand high levels of stress caused by pressure, flow and vibration. Two standard thermowell materials – 316L (1.4404)) and 316Ti (1.4571) – are available.

Applications

25WD_08.TIF

• Power generation and heat distribution • Chemical process engineering

Figure 16: Thermometer with Flanged Barstock Thermowell.

31

Sensors and Assemblies

Figure 17: Series 65 RTD and Series 185 Thermocouple Assemblies with Flanged Barstock Thermowell – Dimensional Drawing. Sensor Design

Connection Heads Model: Rosemount Model: BUKH Aluminum, Stainless Steel Polyamide Codes C, D, G, H, 1, 2, 3, 4 Code T

Model: TZ-A/BL Aluminum Code L

Sensors and Assemblies

Mounting Example

Model: GR-A/BL Aluminum Code J

Model: GN-BL Aluminum Code U

Sensor Lead Wire Terminations, see Figure 7

Extensions and Options Welded-on Threaded Connections Parallel (G, M) Tapered (R, NPT) Codes A, C, E, T Codes B, D

Nipple-Union Code J

Nipple-Union-Nipple Code F

Thermowells

L

32

= Sensor Length

N = Extension Length N K = Extension Length (tapered) NZ = Extension Length (parallel)

U

= Immersion Length

Dimensions in millimeters

25_3b_abb17.tif

Similar to Form 4F, DIN 43772, Flange Code L04 - L88, H10 - H28

Sensors and Assemblies

Ordering Information: Series 65 Platinum RTD WITH Series 96 Flanged Barstock Thermowell (Part 1 of 3) 0065 Code C(2) D(2) G(2) H(2) J(2) L(2) T(2) U(3) 1 2 3 4 N Code 0 1 2 3(4) Code 1 2 3 4 Code A B C D E T F J N Code 0000 0080 0110 0135 0149 XXXX Code D Y Code 0080 0140 0200 0320 0500 XXXX 1) (2) (3) (4) (5)

Description Resistance Thermometer, Pt 100, Class B, suitable for Transmitter Mounting Connection Head Material IP Rating (1) Conduit Connection Thread Rosemount, Aluminum 68 M20 x 1.5 (cable entry) Rosemount, Aluminum 68 ½-inch NPT (cable entry) Rosemount, Stainless Steel 68 M20 x 1.5 (cable entry) Rosemount, Stainless Steel 68 ½-inch NPT (cable entry) GR-A/BL (BUZ), Aluminum 65 M20 x 1.5 TZ-A/BL (BUZH), Aluminum 65 M20 x 1.5 BUKH, Polyamide, Black 65 M20 x 1.5 GN-BL, Aluminum 54 M20 x 1.5 Rosemount, Aluminum with LCD Meter Cover 68 M20 x 1.5 (cable entry) Rosemount, Aluminum with LCD Meter Cover 68 ½-inch NPT (cable entry) Rosemount, Stainless Steel with LCD Meter Cover 68 M20 x 1.5 (cable entry) Rosemount, Stainless Steel with LCD Meter Cover 68 ½-inch NPT (cable entry) No Connection Head (For use with sensor lead wire termination code 3) Sensor Lead Wire Termination Flying Leads – No Springs on DIN plate (For use with models 644, 244E transmitters rev. 5 or later and model 144) Flying Leads – Springs on DIN plate (For use with models 644, 244E transmitters rev. 4 or earlier) Terminal Block – DIN 43762 Spring-Loaded Adapter – ½-inch NPT (For use with connection head option code N) Sensor Type Temperature Range [°C] (5) Single Elements -50 to 450 Dual Elements -50 to 450 Single Elements -196 to 600 Dual Elements -196 to 600 Extension Type Head Connection Instrument Connection Material DIN Standard M24 x 1.5 M24 x 1.5 Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 ½-inch BSPT (R ½-inch) Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 ½-inch BSPF (G ½) Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 ½-inch NPT Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 M20 x 1.5 Stainless Steel (min. length N = 35 mm) DIN Standard M24 x 1.5 M18 x 1.5 Stainless Steel (min. length N = 35 mm) Nipple-Union-Nipple ½-inch NPT ½-inch NPT Stainless Steel (min. length N = 110 mm) Nippel-Nnion (No head) ½-inch NPT Stainless Steel (min. length N = 80 mm) No Extension (For use with extension length (N) Code 0000 and sensor lead wire termination code 3) Extension Length (N) in Millimeters No Extension (For use with extension type code N) 80 (Standard for extension type code J) 110 (Standard for extension type code F and J) 135 (Standard for DIN extension used with Rosemount connection head material codes C, D, G, H, 1, 2, 3, 4) 149 (Standard for DIN extension used with Form B connection head material codes J, L, T, and U) Non-Standard Extension Length Thermowell Material AISI 316L (1.4404) AISI 316Ti (1.4571) Immersion Length (Uk,Uz) in Millimeters 80 140 200 320 500 Non-Standard Immersion Length Note: Non-standard lengths are available from 80 to 900 mm.

IP 68 rating requires a suitable cable gland on the conduit connection thread. All threads must be sealed. Connection head suitable for mounting a transmitter (model 144, 244, and 644). Connection head suitable for mounting a transmitter (model 144). For use with connection head code N and extension type code J or N. Temperature range valid for tolerance class B only.

33

Sensors and Assemblies

Model

Sensors and Assemblies