Alloy Steels Scm440 2w4b50

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3i3n4

Overview 26281t

& View Alloy Steels Scm440 as PDF for free.

More details 6y5l6z

- Words: 292

- Pages: 2

Gloria Material Technology Corp.

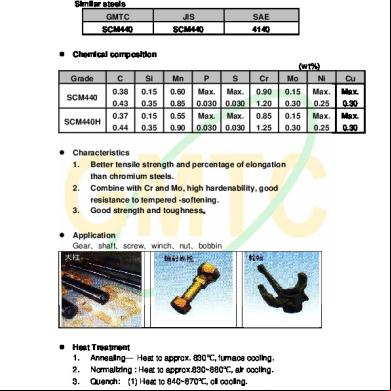

Alloy steels (SCM440) Similar steels

z

GMTC

JIS

SAE

SCM440

SCM440

4140

Chemical composition (wt%) Grade

C

Si

Mn

P

S

Cr

Mo

Ni

Cu

SCM440

0.38 0.43

0.15 0.35

0.60 0.85

Max. 0.030

Max. 0.030

0.90 1.20

0.15 0.30

Max. 0.25

Max. 0.30

SCM440H

0.37 0.44

0.15 0.35

0.55 0.90

Max. 0.030

Max. 0.030

0.85 1.25

0.15 0.30

Max. 0.25

Max. 0.30

z

Characteristics 1. Better tensile strength and percentage of elongation than chromium steels. 2. Combine with Cr and Mo, high hardenability, good resistance to tempered -softening. 3. Good strength and toughness。

z

Application Gear、shaft、screw、winch、nut、bobbin

z

Heat Treatment 1. Annealing— Heat to approx. 830℃, furnace cooling. 2. Normalizing : Heat to approx.830~880℃, air cooling. 3. Quench: (1) Heat to 840~870℃, oil cooling. 4. Tempering: Heat to approx. 550~650℃, water cooling.

GMTC G

R

O

U

P

1

z

Mechanical properties

Hardness HB Anneali Quench-Te ng mpering max.25 5 z

Impact Percentag Percentag Yield Tensile value e of e of area strength strength (charpy) 2 2 elongation reduction N/mm N/mm J/cm2 %

285-352

>830

>980

>12

>45

>59

Hardenability Curve

Temp.℃ mm Normali 1.5 3 5 7 9 11 13 15 20 25 30 35 40 45 50 Quench HRC zing Max. 60 60 60 59 58 58 57 56 55 53 51 49 47 46 44 870 845 Min. 53 53 52 51 50 48 46 43 38 35 33 33 32 31 30 Distance from quenched end (mm)

70

Hardness,HRC

60 50 40 30 20 10 0 1.5 3 5 7 9 11 13 15 20 25 30 35 40 45 50

Distance from quenched end,mm

z

Availability 1. Annealing、Spheroidizing and QT condition. 2. Available size range: φ660mm.

GMTC G

R

O

U

P

2

Alloy steels (SCM440) Similar steels

z

GMTC

JIS

SAE

SCM440

SCM440

4140

Chemical composition (wt%) Grade

C

Si

Mn

P

S

Cr

Mo

Ni

Cu

SCM440

0.38 0.43

0.15 0.35

0.60 0.85

Max. 0.030

Max. 0.030

0.90 1.20

0.15 0.30

Max. 0.25

Max. 0.30

SCM440H

0.37 0.44

0.15 0.35

0.55 0.90

Max. 0.030

Max. 0.030

0.85 1.25

0.15 0.30

Max. 0.25

Max. 0.30

z

Characteristics 1. Better tensile strength and percentage of elongation than chromium steels. 2. Combine with Cr and Mo, high hardenability, good resistance to tempered -softening. 3. Good strength and toughness。

z

Application Gear、shaft、screw、winch、nut、bobbin

z

Heat Treatment 1. Annealing— Heat to approx. 830℃, furnace cooling. 2. Normalizing : Heat to approx.830~880℃, air cooling. 3. Quench: (1) Heat to 840~870℃, oil cooling. 4. Tempering: Heat to approx. 550~650℃, water cooling.

GMTC G

R

O

U

P

1

z

Mechanical properties

Hardness HB Anneali Quench-Te ng mpering max.25 5 z

Impact Percentag Percentag Yield Tensile value e of e of area strength strength (charpy) 2 2 elongation reduction N/mm N/mm J/cm2 %

285-352

>830

>980

>12

>45

>59

Hardenability Curve

Temp.℃ mm Normali 1.5 3 5 7 9 11 13 15 20 25 30 35 40 45 50 Quench HRC zing Max. 60 60 60 59 58 58 57 56 55 53 51 49 47 46 44 870 845 Min. 53 53 52 51 50 48 46 43 38 35 33 33 32 31 30 Distance from quenched end (mm)

70

Hardness,HRC

60 50 40 30 20 10 0 1.5 3 5 7 9 11 13 15 20 25 30 35 40 45 50

Distance from quenched end,mm

z

Availability 1. Annealing、Spheroidizing and QT condition. 2. Available size range: φ660mm.

GMTC G

R

O

U

P

2