Enu - Pt Tjb Power Services - Cation Train #b - Si000451 - 00564100.pdf 66e44

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 3i3n4

Overview 26281t

& View Enu - Pt Tjb Power Services - Cation Train #b - Si000451 - 00564100.pdf as PDF for free.

More details 6y5l6z

- Words: 729

- Pages: 4

Analytical Resources 21 Gul Lane Jurong Singapore 629416 Phone: 65-6505-6642 Fax: 65-6505-6781 Email: [email protected]

Final - Report Number: 564100 PT TJB POWER SERVICES PLTU TANJUNG JATI B - JAWA TENGAH - 59453 - INDONESIA Representative: Yuli Hartanto

Sample number: Date sampled: Date received: Date completed: Date authorized:

Sample taken from: Cation Train #B

SI000451 10-Feb-2012 27-Feb-2012 8-Mar-2012 8-Mar-2012

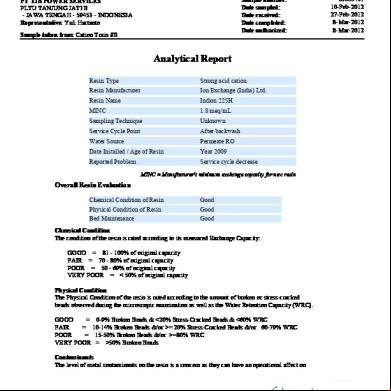

Analytical Report Resin Type

Strong acid cation

Resin Manufacturer

Ion Exchange (India) Ltd.

Resin Name

Indion 225H

MINC

1.8 meq/mL

Sampling Technique

Unknown

Service Cycle Point

After backwash

Water Source

Permeate RO

Date Installed / Age of Resin

Year 2009

Reported Problem

Service cycle decrease MINC = Manufacturer's minimum exchange capacity for new resin

Overall Resin Evaluation Chemical Condition of Resin Physical Condition of Resin Bed Maintenance

Good Good Good

Chemical Condition The condition of the resin is rated according to its measured Exchange Capacity: GOOD = 81 - 100% of original capacity FAIR = 70 - 80% of original capacity POOR = 50 - 69% of original capacity VERY POOR = < 50% of original capacity Physical Condition The Physical Condition of the resin is rated according to the amount of broken or stress-cracked beads observed during the microscopic examination as well as the Water Retention Capacity (WRC). GOOD = 0-9% Broken Beads & <20% Stress-Cracked Beads & <60% WRC FAIR = 10-14% Broken Beads &/or >= 20% Stress-Cracked Beads &/or 60-79% WRC POOR = 15-50% Broken Beads &/or >=80% WRC VERY POOR = >50% Broken Beads Contaminants The level of metal contaminants on the resin is a concern as they can have an operational affect on

Authorized by Tingnan Edwin Lin Page 1 of 4

Analytical Resources 21 Gul Lane Jurong Singapore 629416 Phone: 65-6505-6642 Fax: 65-6505-6781 Email: [email protected]

Final - Report Number: 564100 PT TJB POWER SERVICES PLTU TANJUNG JATI B - JAWA TENGAH - 59453 - INDONESIA Representative: Yuli Hartanto Sample taken from: Cation Train #B

Sample number: Date sampled: Date received: Date completed: Date authorized:

SI000451 10-Feb-2012 27-Feb-2012 8-Mar-2012 8-Mar-2012

the unit's performance. See the recommendation section for a suggested cleaning procedure. Recommendations Based on the types and amounts of contaminants present on the resin, we recommend application of C1000 - Cation Resin Cleaning Procedure. Clean-up procedures for Ion Exchange resins are located in the Knowledge Management System (KMS) of Lotus Notes. Search the KMS database for the procedure title. An alternative is to perform a more general search of the KMS. Type "Resin Cleaning" in the search keywords field and click on

. Then scan the resulting documents for the desired resin cleaning procedure document. Procedures are also available through Nalco sales representives and technicians.

Authorized by Tingnan Edwin Lin Page 2 of 4

Analytical Resources 21 Gul Lane Jurong Singapore 629416 Phone: 65-6505-6642 Fax: 65-6505-6781 Email: [email protected]

Final - Report Number: 564100 PT TJB POWER SERVICES PLTU TANJUNG JATI B - JAWA TENGAH - 59453 - INDONESIA Representative: Yuli Hartanto

Sample number: Date sampled: Date received: Date completed: Date authorized:

Sample taken from: Cation Train #B

SI000451 10-Feb-2012 27-Feb-2012 8-Mar-2012 8-Mar-2012

Capacity Measurements Results represent optimum exchange capacity, not necessarily its current Operating Capacity. Sample Preparation: Routine lab chemical clean-up procedure Ionic Form: H

Total Exchange Capacity (Wet) % Of Original Exchange Capacity Water Retention Capacity

1.7 meq/mL (37.06 Kilograins/ft³) 94 % 53 %

Physical Characteristics Normal Beads Broken Beads Stress Cracked Beads Internal Precipitate On Beads External Precipitate On Beads

99 % <1 % <1 % None Very small amounts

Stress Cracked Broken

Normal

Contaminants Iron (Fe) Strontium (Sr) Aluminum (Al) Lead (Pb) Chlorine (Cl) Bromine (Br)

Metals by X-Ray Fluorescence 1400 g/m³ 210 g/m³ 130 g/m³ 85 g/m³ 85 g/m³ 85 g/m³

The significance of the amount of metal contaminants varies with the type of resin. For this resin type, significant findings:

Small amounts: Al, Br, Cl, Pb Moderate amounts: Fe, Sr

Authorized by Tingnan Edwin Lin Page 3 of 4

Analytical Resources 21 Gul Lane Jurong Singapore 629416 Phone: 65-6505-6642 Fax: 65-6505-6781 Email: [email protected]

Final - Report Number: 564100 PT TJB POWER SERVICES PLTU TANJUNG JATI B - JAWA TENGAH - 59453 - INDONESIA Representative: Yuli Hartanto

Sample number: Date sampled: Date received: Date completed: Date authorized:

Sample taken from: Cation Train #B

SI000451 10-Feb-2012 27-Feb-2012 8-Mar-2012 8-Mar-2012

Additional Observations No particulates were seen in the supernatant.

Strong Acid Cation

Authorized by Tingnan Edwin Lin Page 4 of 4

Final - Report Number: 564100 PT TJB POWER SERVICES PLTU TANJUNG JATI B - JAWA TENGAH - 59453 - INDONESIA Representative: Yuli Hartanto

Sample number: Date sampled: Date received: Date completed: Date authorized:

Sample taken from: Cation Train #B

SI000451 10-Feb-2012 27-Feb-2012 8-Mar-2012 8-Mar-2012

Analytical Report Resin Type

Strong acid cation

Resin Manufacturer

Ion Exchange (India) Ltd.

Resin Name

Indion 225H

MINC

1.8 meq/mL

Sampling Technique

Unknown

Service Cycle Point

After backwash

Water Source

Permeate RO

Date Installed / Age of Resin

Year 2009

Reported Problem

Service cycle decrease MINC = Manufacturer's minimum exchange capacity for new resin

Overall Resin Evaluation Chemical Condition of Resin Physical Condition of Resin Bed Maintenance

Good Good Good

Chemical Condition The condition of the resin is rated according to its measured Exchange Capacity: GOOD = 81 - 100% of original capacity FAIR = 70 - 80% of original capacity POOR = 50 - 69% of original capacity VERY POOR = < 50% of original capacity Physical Condition The Physical Condition of the resin is rated according to the amount of broken or stress-cracked beads observed during the microscopic examination as well as the Water Retention Capacity (WRC). GOOD = 0-9% Broken Beads & <20% Stress-Cracked Beads & <60% WRC FAIR = 10-14% Broken Beads &/or >= 20% Stress-Cracked Beads &/or 60-79% WRC POOR = 15-50% Broken Beads &/or >=80% WRC VERY POOR = >50% Broken Beads Contaminants The level of metal contaminants on the resin is a concern as they can have an operational affect on

Authorized by Tingnan Edwin Lin Page 1 of 4

Analytical Resources 21 Gul Lane Jurong Singapore 629416 Phone: 65-6505-6642 Fax: 65-6505-6781 Email: [email protected]

Final - Report Number: 564100 PT TJB POWER SERVICES PLTU TANJUNG JATI B - JAWA TENGAH - 59453 - INDONESIA Representative: Yuli Hartanto Sample taken from: Cation Train #B

Sample number: Date sampled: Date received: Date completed: Date authorized:

SI000451 10-Feb-2012 27-Feb-2012 8-Mar-2012 8-Mar-2012

the unit's performance. See the recommendation section for a suggested cleaning procedure. Recommendations Based on the types and amounts of contaminants present on the resin, we recommend application of C1000 - Cation Resin Cleaning Procedure. Clean-up procedures for Ion Exchange resins are located in the Knowledge Management System (KMS) of Lotus Notes. Search the KMS database for the procedure title. An alternative is to perform a more general search of the KMS. Type "Resin Cleaning" in the search keywords field and click on

Authorized by Tingnan Edwin Lin Page 2 of 4

Analytical Resources 21 Gul Lane Jurong Singapore 629416 Phone: 65-6505-6642 Fax: 65-6505-6781 Email: [email protected]

Final - Report Number: 564100 PT TJB POWER SERVICES PLTU TANJUNG JATI B - JAWA TENGAH - 59453 - INDONESIA Representative: Yuli Hartanto

Sample number: Date sampled: Date received: Date completed: Date authorized:

Sample taken from: Cation Train #B

SI000451 10-Feb-2012 27-Feb-2012 8-Mar-2012 8-Mar-2012

Capacity Measurements Results represent optimum exchange capacity, not necessarily its current Operating Capacity. Sample Preparation: Routine lab chemical clean-up procedure Ionic Form: H

Total Exchange Capacity (Wet) % Of Original Exchange Capacity Water Retention Capacity

1.7 meq/mL (37.06 Kilograins/ft³) 94 % 53 %

Physical Characteristics Normal Beads Broken Beads Stress Cracked Beads Internal Precipitate On Beads External Precipitate On Beads

99 % <1 % <1 % None Very small amounts

Stress Cracked Broken

Normal

Contaminants Iron (Fe) Strontium (Sr) Aluminum (Al) Lead (Pb) Chlorine (Cl) Bromine (Br)

Metals by X-Ray Fluorescence 1400 g/m³ 210 g/m³ 130 g/m³ 85 g/m³ 85 g/m³ 85 g/m³

The significance of the amount of metal contaminants varies with the type of resin. For this resin type, significant findings:

Small amounts: Al, Br, Cl, Pb Moderate amounts: Fe, Sr

Authorized by Tingnan Edwin Lin Page 3 of 4

Analytical Resources 21 Gul Lane Jurong Singapore 629416 Phone: 65-6505-6642 Fax: 65-6505-6781 Email: [email protected]

Final - Report Number: 564100 PT TJB POWER SERVICES PLTU TANJUNG JATI B - JAWA TENGAH - 59453 - INDONESIA Representative: Yuli Hartanto

Sample number: Date sampled: Date received: Date completed: Date authorized:

Sample taken from: Cation Train #B

SI000451 10-Feb-2012 27-Feb-2012 8-Mar-2012 8-Mar-2012

Additional Observations No particulates were seen in the supernatant.

Strong Acid Cation

Authorized by Tingnan Edwin Lin Page 4 of 4